Compression refuse collector and hydraulic system thereof

A hydraulic system and hydraulic oil technology, which is applied in the hydraulic system field of compressed garbage trucks, can solve the problems of slow moving speed of the compression mechanism, large flow fluctuation, and confluence working conditions, etc., and achieve beautiful and concentrated appearance, stable operating flow, Effect of reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

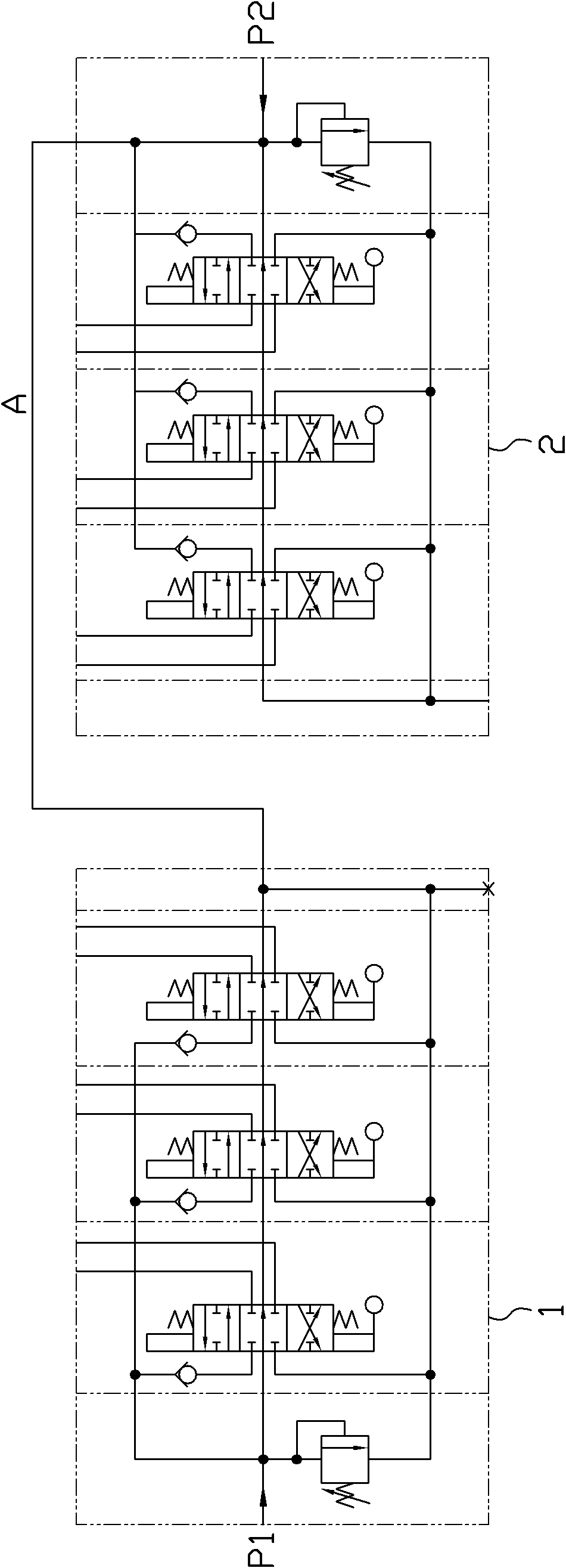

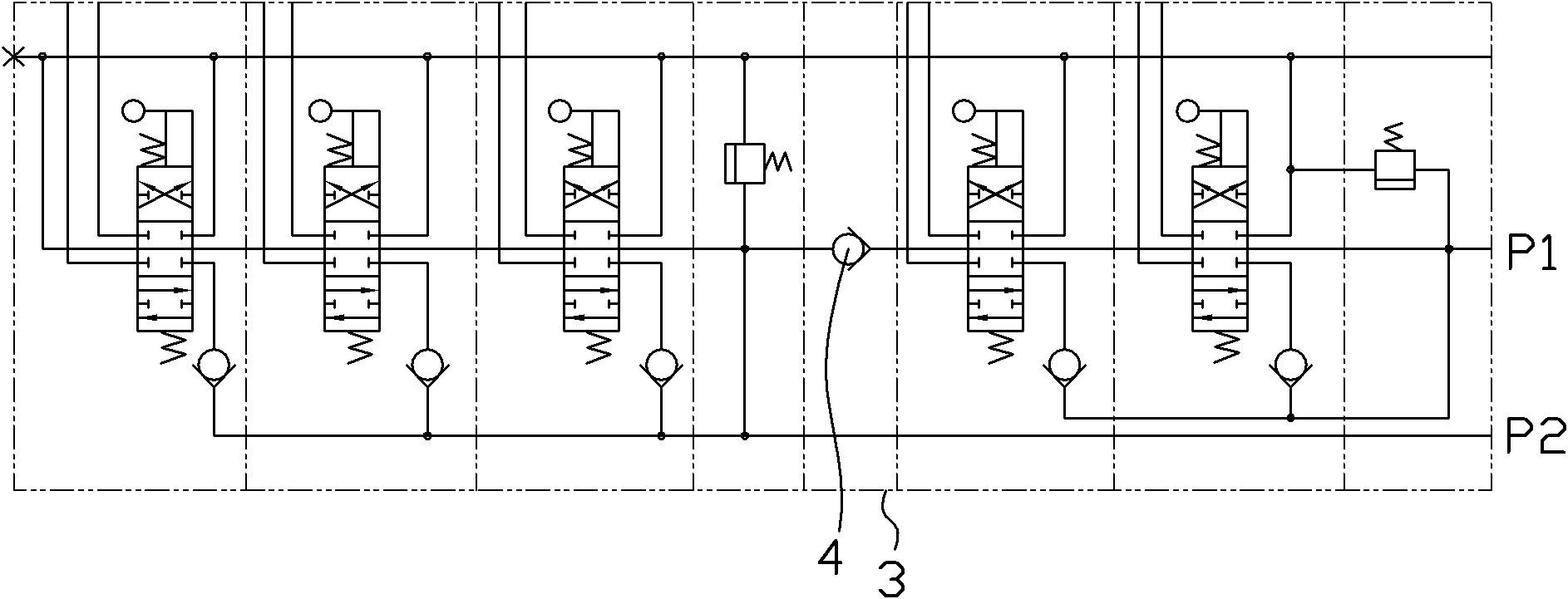

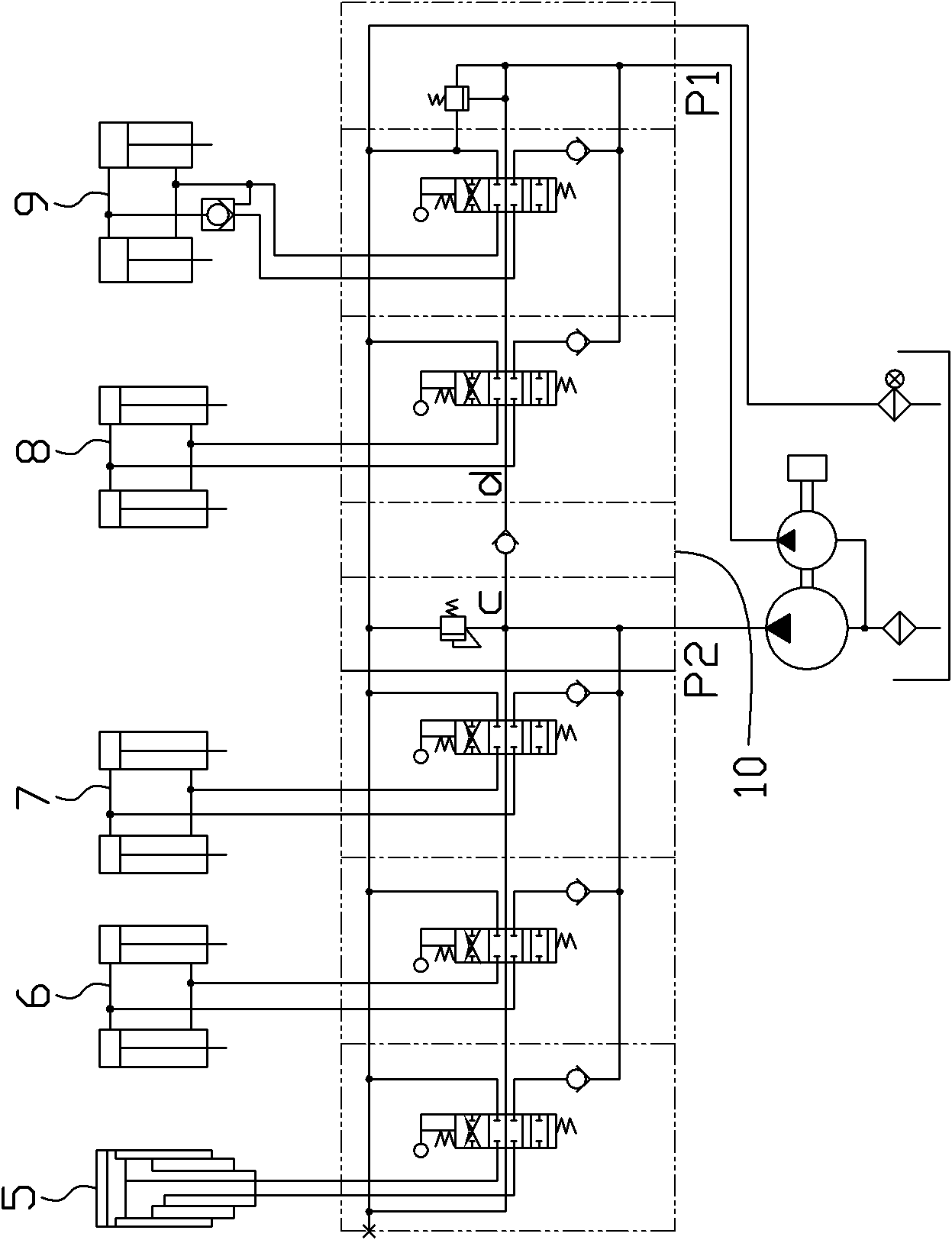

[0022] Figure 4 It is a schematic diagram of the principle of the hydraulic system of the compression garbage truck in the embodiment of the present invention. Please refer to Figure 4 , In this embodiment, the hydraulic system includes a main valve 20 , a double oil pump 30 , an oil tank 40 , a first oil cylinder system 50 , a second oil cylinder system 52 , and a total oil passage 60 . The dual oil pump 30 includes a first oil pump 32 and a second oil pump 34 . The oil tank 40 is connected with the double oil pump 30 , and the double oil pump 30 is connected with the main valve 20 . The main oil passage 60 includes a first oil inlet P1, a second oil inlet P2, a first oil return port T1, and a second oil return port T2. In this embodiment, the hydraulic oil in the main oil passage 60 passes through the first oil return port T2. Oil can be returned through the first oil return port T1, of course, oil can also be returned through the second oil return port T2 according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com