Waterproof construction method and system for bottom plate of high-water-level basement

A basement floor and construction method technology, which is applied in infrastructure engineering, construction, etc., can solve problems such as labor and material costs, and achieve the effects of simple materials, cost saving, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

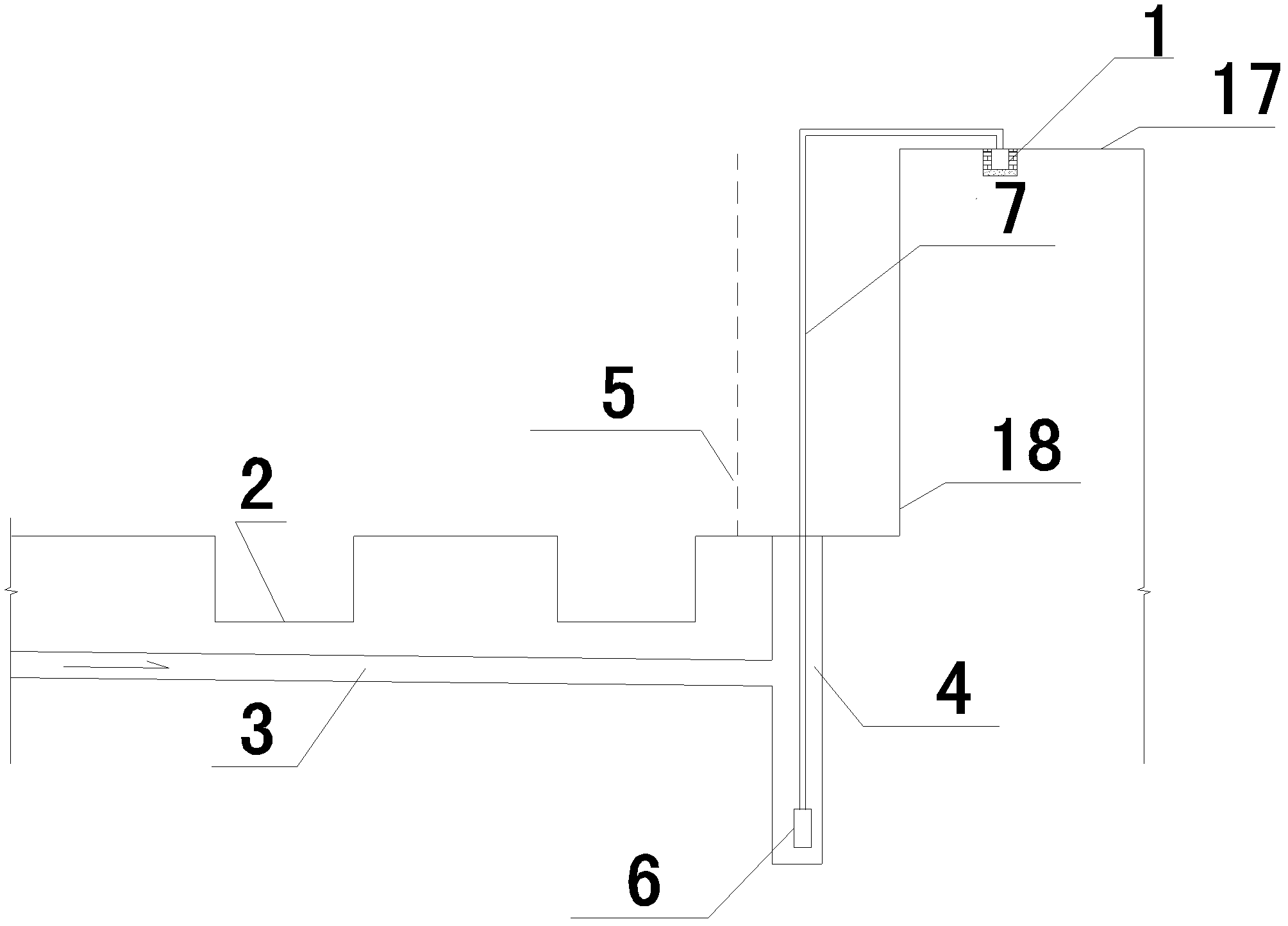

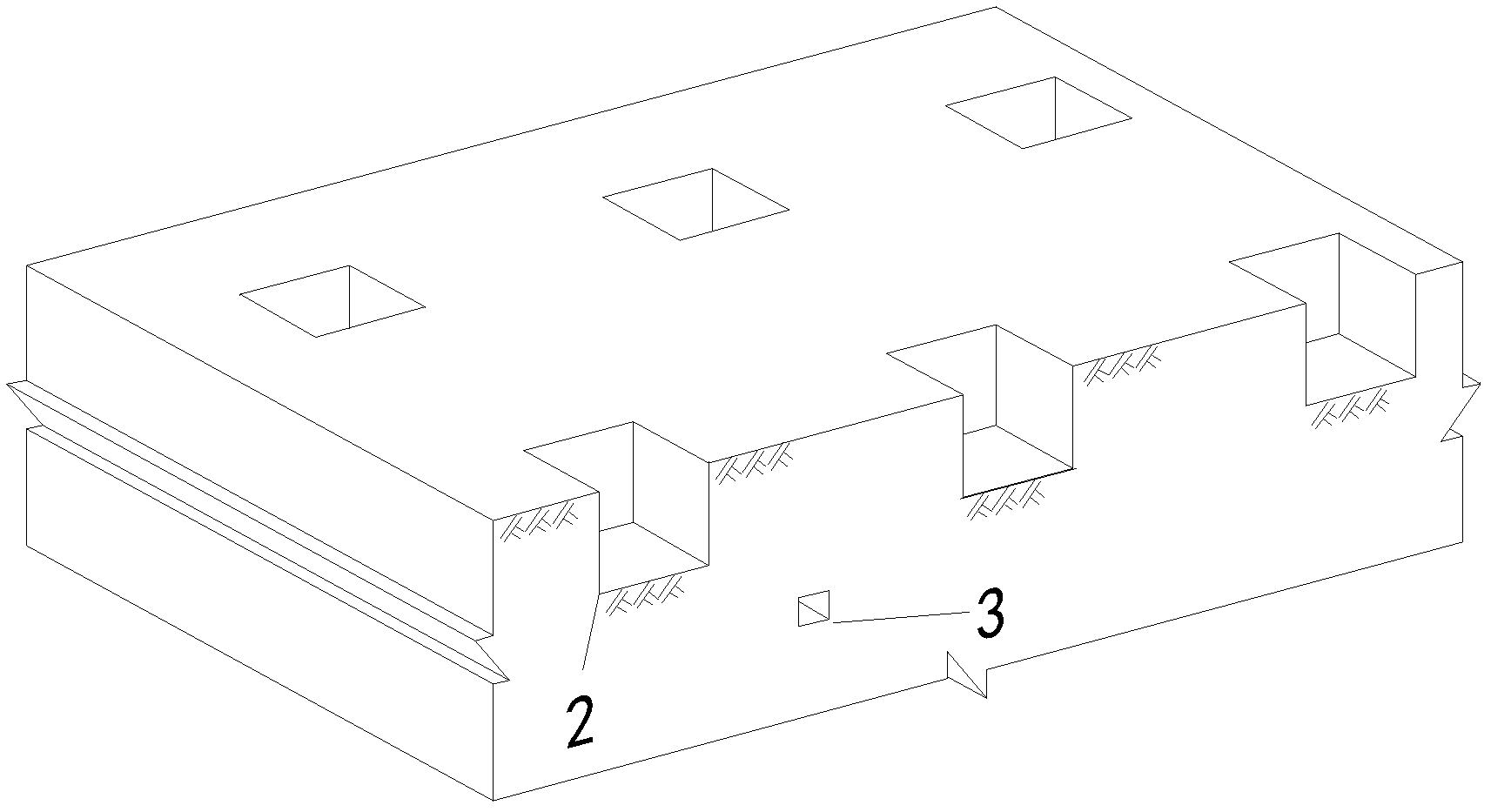

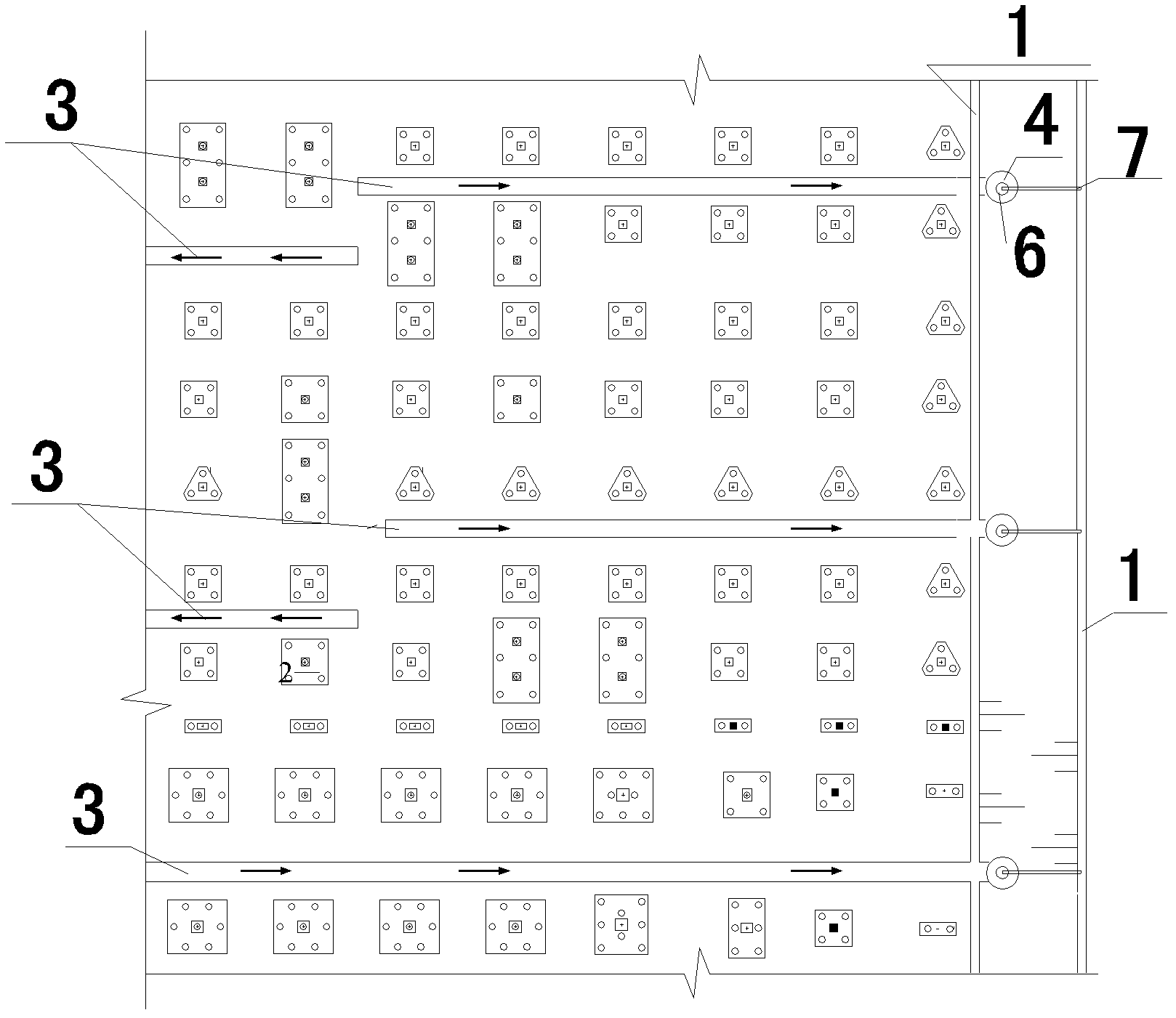

[0038] Such as Figure 1~5 Shown, a kind of high water level basement basement waterproof construction method comprises the following steps:

[0039] (1) First, use the water-stop curtain of the foundation pit support to stop the water in the soil layer in the depth range of the foundation pit 18 from the periphery of the foundation pit 17, and at the same time, set a through hole on the ground 17 of the foundation pit support and the periphery of the bottom of the foundation pit. gutter 1;

[0040] (2) Set up more than one drainage ditch 3 made of loose bricks and fiber nets below the interval between the pile caps of the basement floor, and the bottom 2 of the pile caps is 500-1000 mm from the top of the drainage ditch 3;

[0041](3) Corresponding dewatering wells 4 are arranged at the outlet of the drainage ditch 3 around the foundation pit 1, and the dewatering wells 4 are arranged outside the outermost edge 5 of the basement foundation. It communicates with the drainage...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 lies in that the planar layout of the drain ditch 3 in the step (2) is a curved structure, and the outlet end of the drain ditch 3 communicates with the dewatering well 4 in the step (3). That is to say, the drainage ditch 3 in the present embodiment can be bent between the caps, as long as the water can be sent to the dewatering well 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com