Multi-continuous-electrode electrolytic tank for preparation of high-performance aluminum material

A continuous electrode and aluminum material technology, which is applied in the field of high-performance aluminum material preparation devices, can solve the problems of high energy consumption, high performance requirements, complex process, and high cost, and achieve low operating costs, long-term normal work, and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

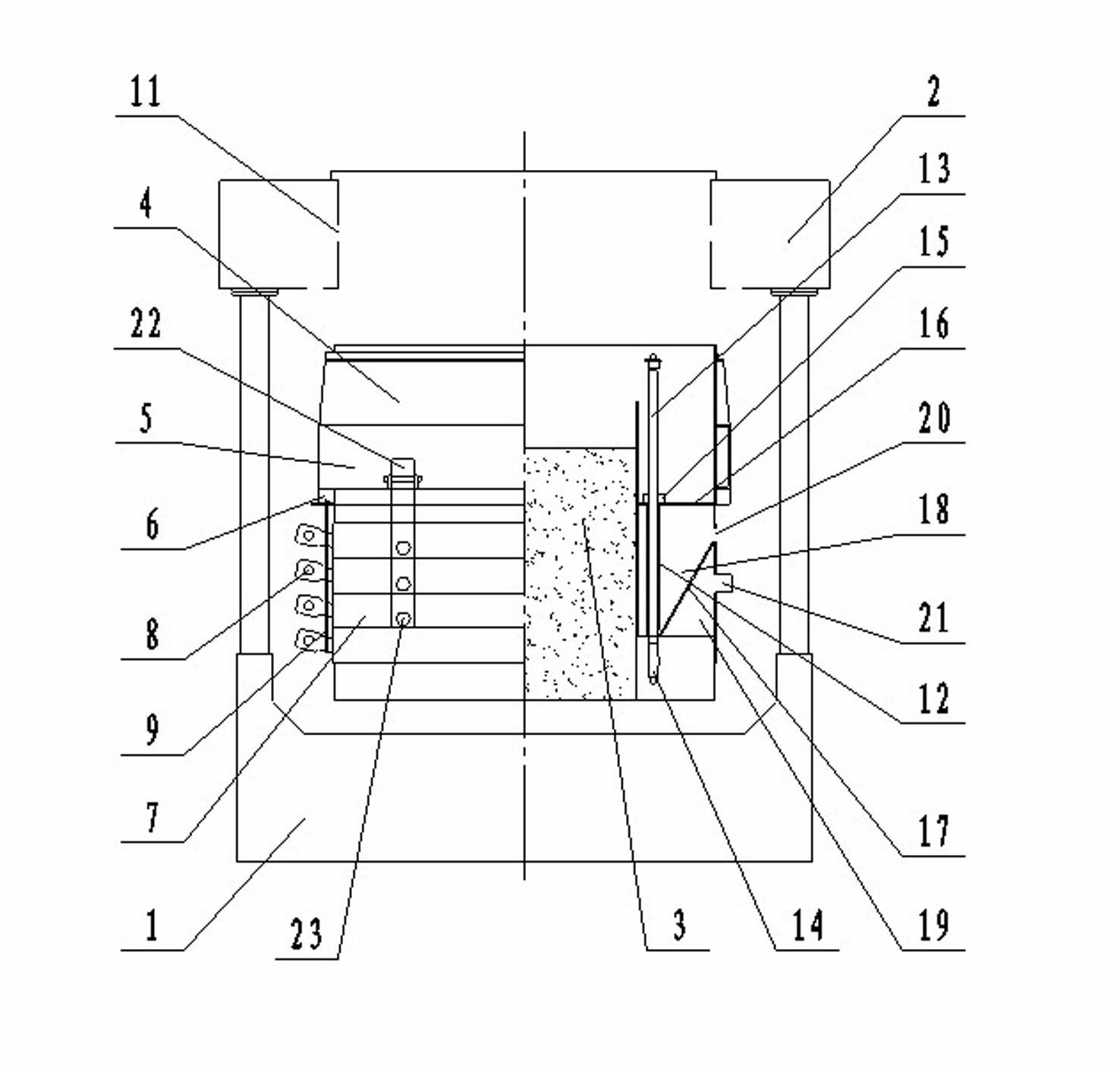

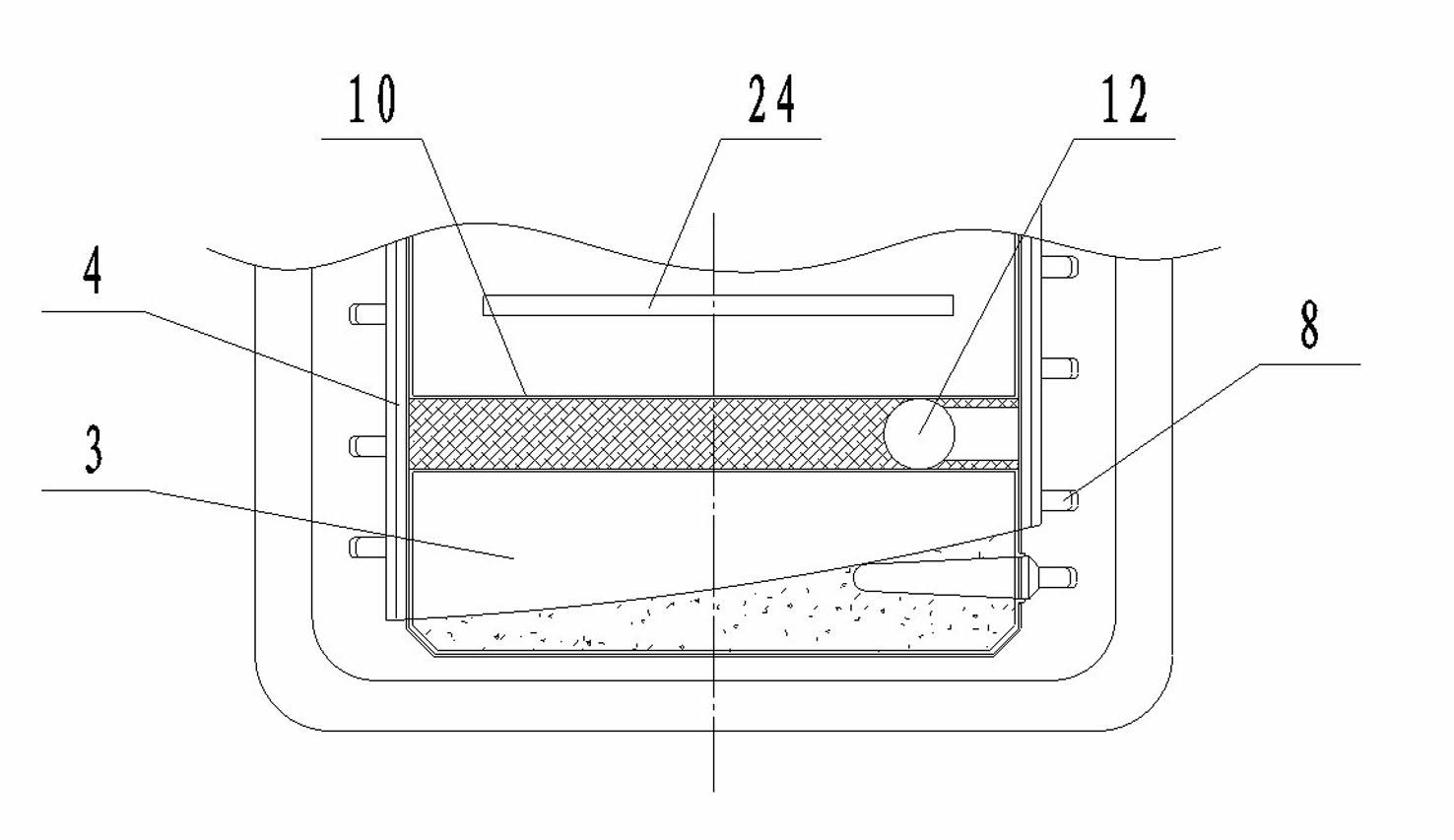

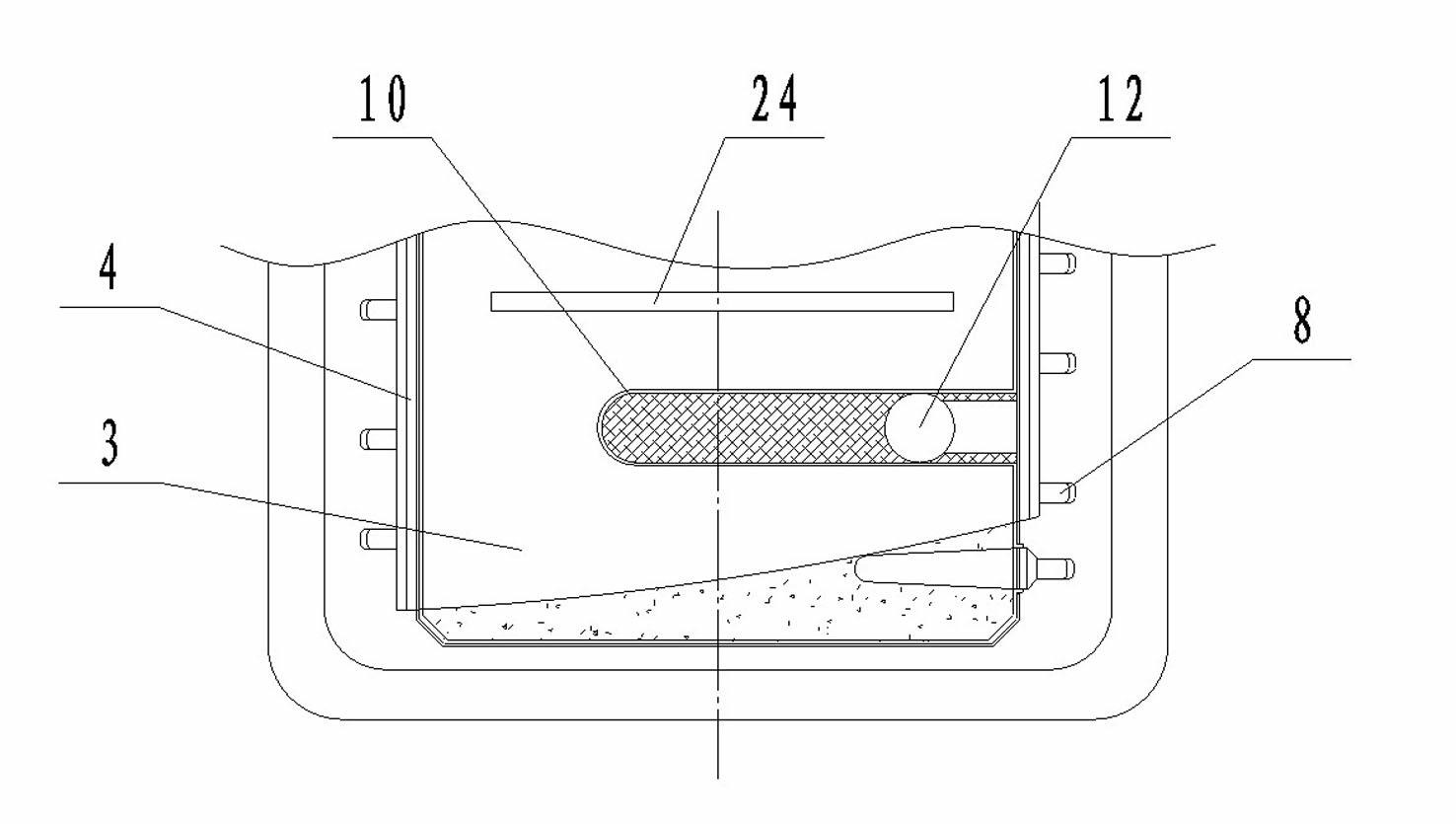

[0018] A multi-continuous electrode electrolytic cell for the preparation of high-performance aluminum materials, including a continuous electrode device, a cathode device 1, and a metal platform 2 located above the continuous electrode device, the number of continuous electrode devices is one or more, and a single continuous electrode device is composed of four sides The wall is covered with aluminum foil or aluminum plates and consists of several electrode bodies 3 and electrode boxes distributed front and back. The upper part of the electrode box is provided with one or more sleeve-shaped metal frames 4 that are sleeved around the electrode body 3, and the outer wall of the metal frame 4 is set. There is a load-bearing fastening ring 5, and load-bearing hook connectors 6 are fixed around the lower side of the load-bearing fastening ring 5. The lower part of the electrode box is provided with a number of sealing cover frames 7 arranged up and down. The main body 3 is formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com