Super-high strength cold rolled steel belt suitable for rolling formation and manufacture method of super-high strength cold rolled steel belt

An ultra-high-strength, roll-forming technology, which is applied in the field of roll-formed ultra-high-strength cold-rolled steel strip and its manufacturing, can solve the problem of large anisotropy of bending performance, difficulty in obtaining part shape, uneven structure and performance, etc. problem, to achieve low anisotropy, moderate hardenability, and a small number of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with embodiment.

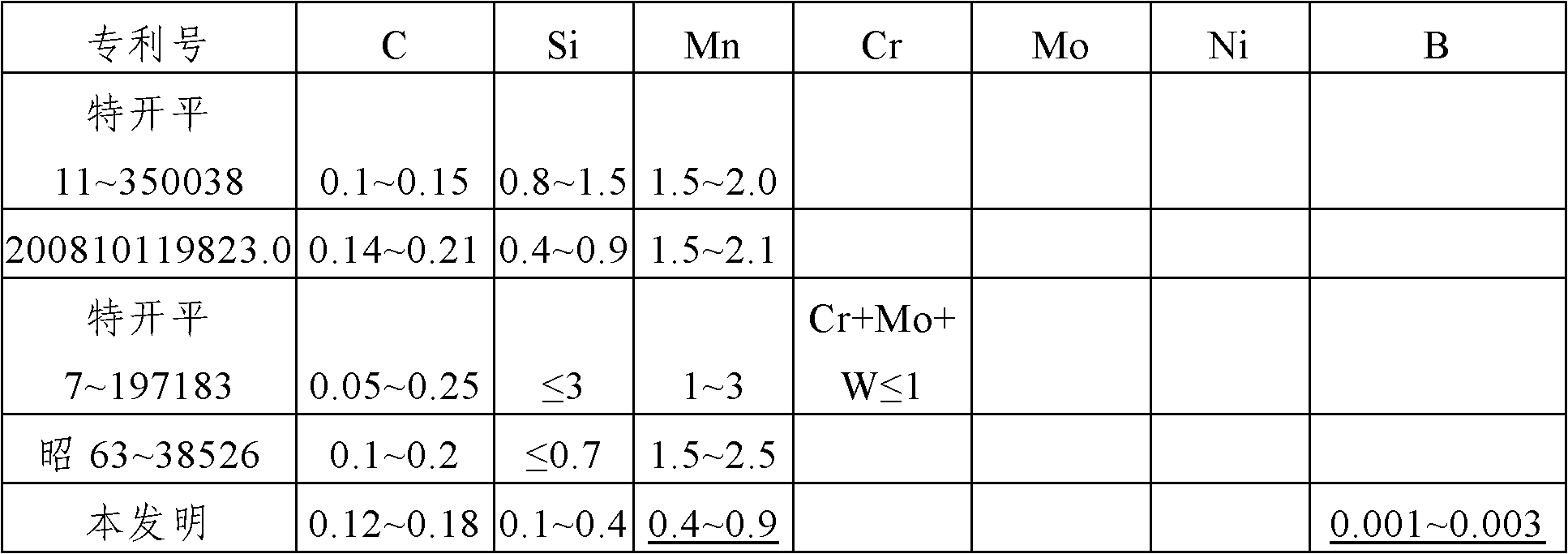

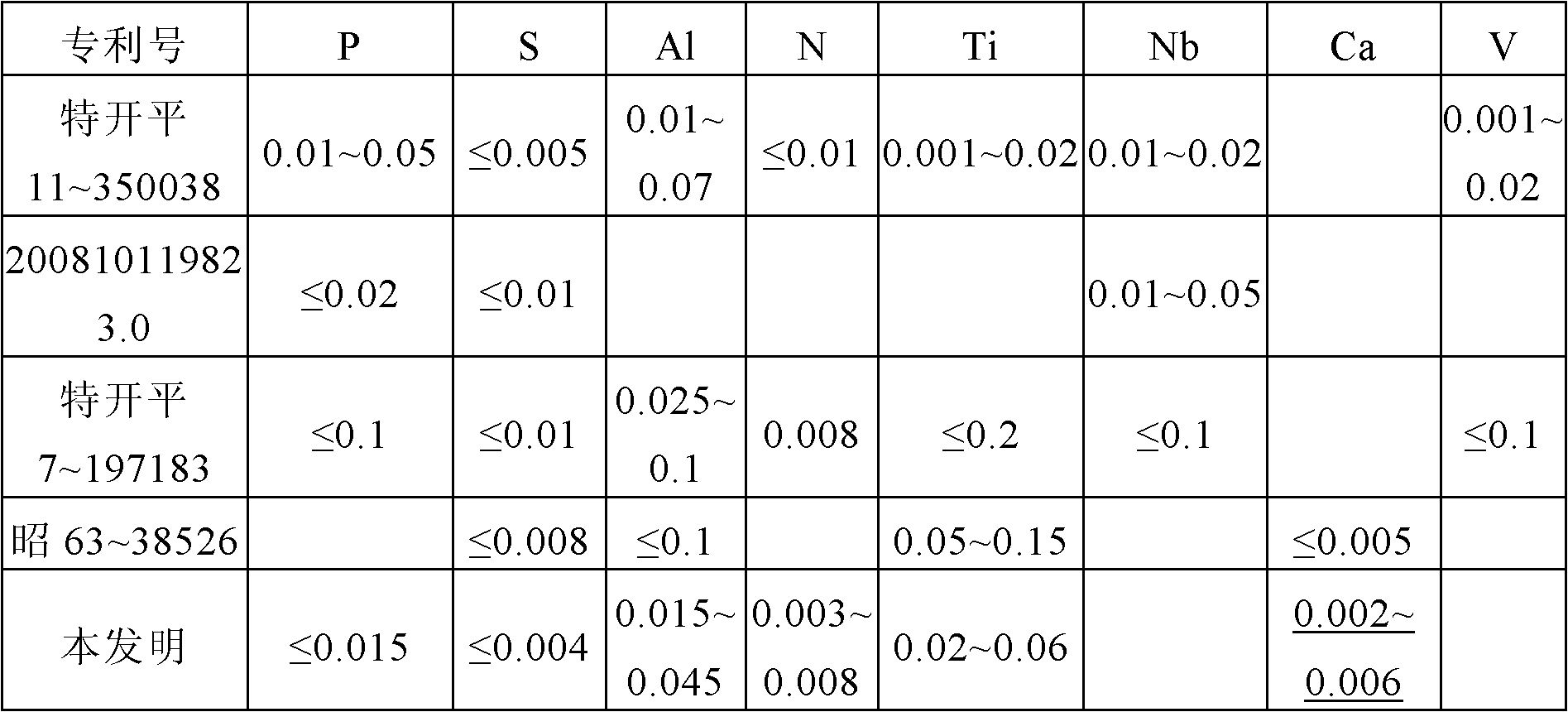

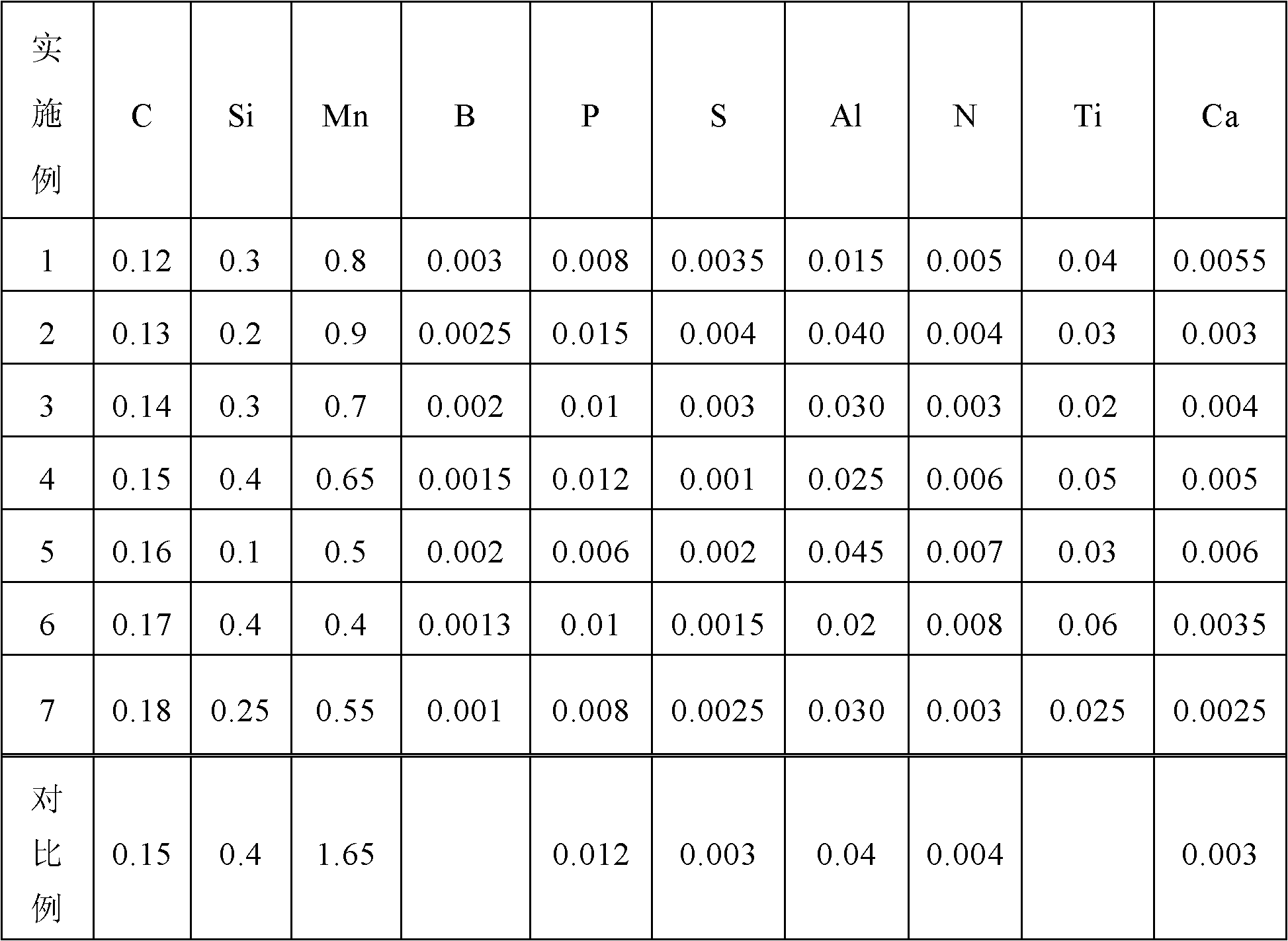

[0050] See Table 3 for the chemical composition of the steel in the embodiment of the present invention. The technical conditions of the steel of the present invention are shown in Table 4, and the strength obtained after smelting, hot rolling, cold rolling, annealing and smoothing of the steel of the present invention is shown in Table 5. As can be seen from Table 5, according to the present invention can produce the high-strength steel of strength more than 980MPa, compared with commercially available high-strength steel of equal strength (comparative example 1), cold bending performance is good, bending performance anisotropy is low, can Better meet the requirements of roll forming. Suitable for the manufacture of high-strength body parts. In terms of band structure control, cold-bending anisotropy control and cost, the steel of the invention is different from and superior to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com