Method for cleanly producing glutamic acid, gamma-polyglutamic acid and organic fertilizer

A technology of polyglutamic acid and clean production, which is applied in the direction of organic fertilizers, methods based on microorganisms, and the preparation of organic compounds, can solve the problems of high operating costs, heavy burdens on enterprises, and low economic benefits, and reduce the cost of environmental protection The effect of pressure, increasing the economic benefits of enterprises, and improving the competitiveness of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

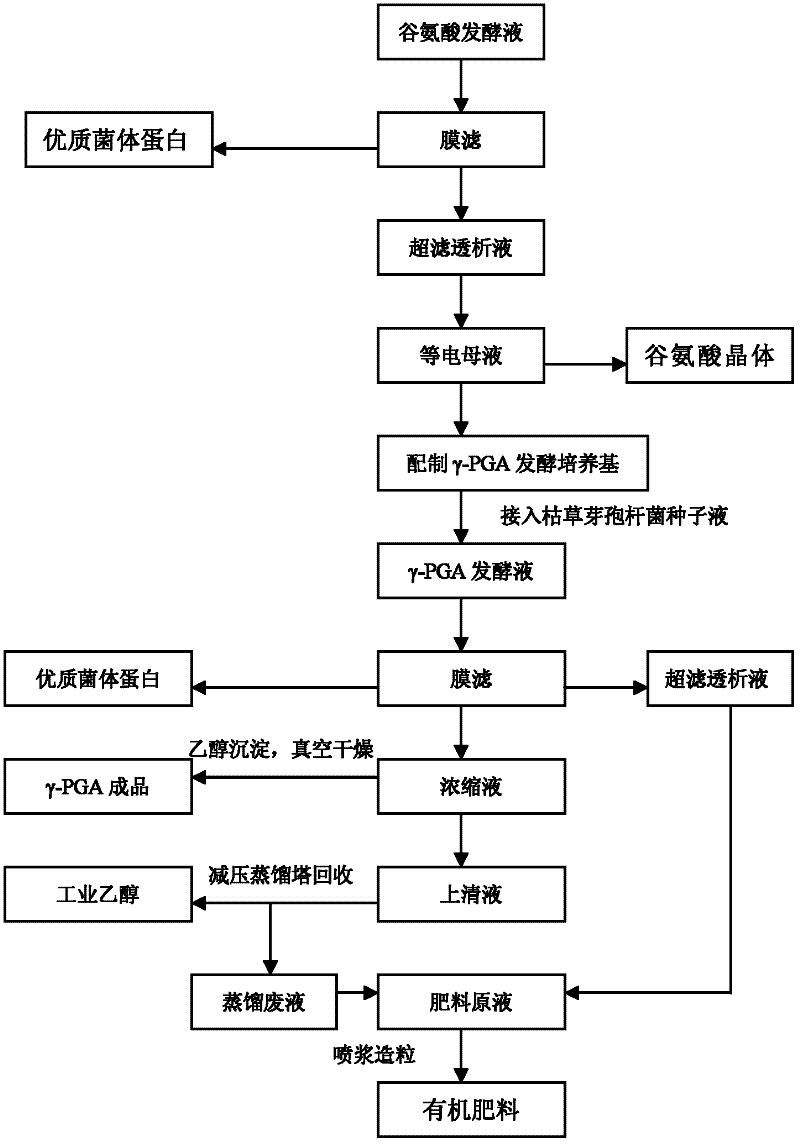

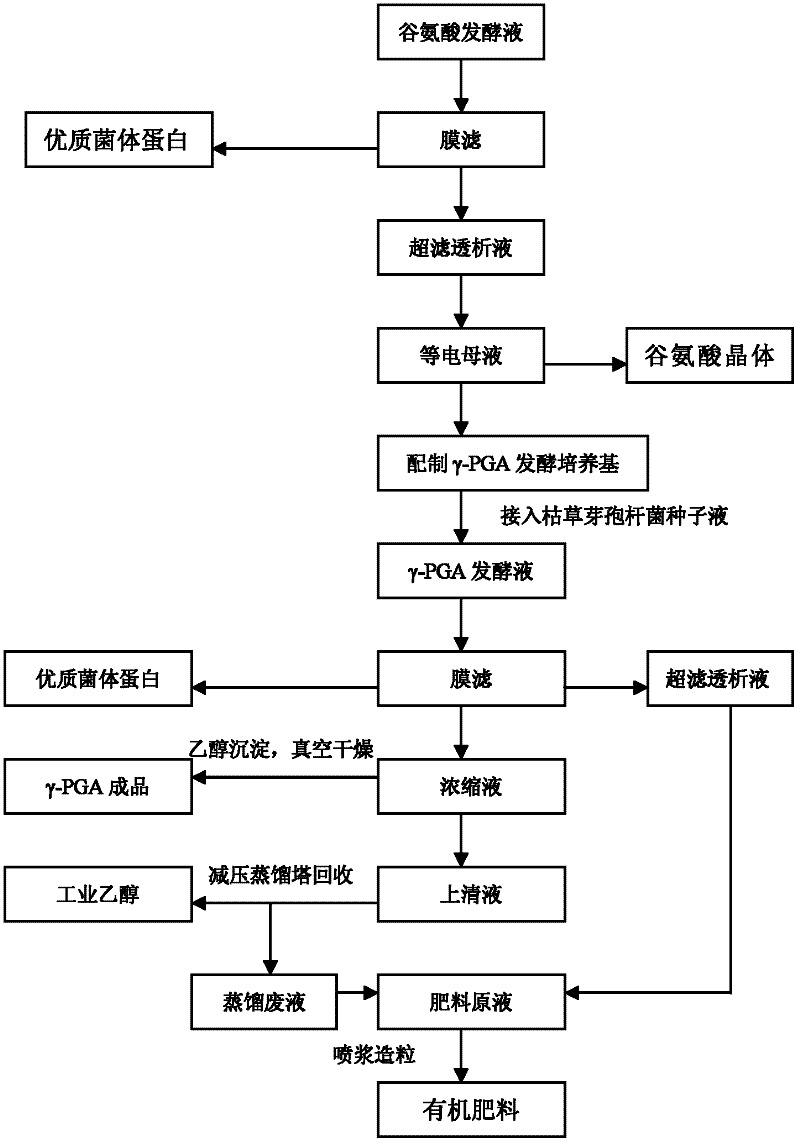

[0024] Refer to attached figure 1 The production process flow of the present invention is described.

[0025] Filter 60L glutamic acid fermentation broth through microfiltration membrane to remove bacteria and other foreign proteins in glutamic acid fermentation broth, obtain 120L microfiltration dialysate and bacterial protein, and filter 120L microfiltration dialysate through ultrafiltration membrane Obtain 30L of ultrafiltration dialyzate and concentrated solution, mix the concentrated solution and bacterial protein and dry to obtain 1.18kg of high-quality bacterial protein feed, wherein the microfiltration temperature and ultrafiltration temperature are both 20-60°C, microfiltration The difference between the feed liquid inlet pressure and outlet pressure is 0.1-0.4Mpa; the above-mentioned microfiltration membrane is a ceramic membrane with a molecular weight cut-off of 2000-50000MW, a pore size of 0.1-10μm, and a microfiltration temperature of 20-60°C; The ultrafiltratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com