Bacillus subtilis, preparation, preparation method of preparation, and application of bacillus subtilis and preparation

A Bacillus subtilis and preparation technology, applied in the field of biological pesticides, can solve the problems of poor drug resistance and safety, poor antibacterial effect, and need to improve the killing or inhibition effect, and achieve a significant control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

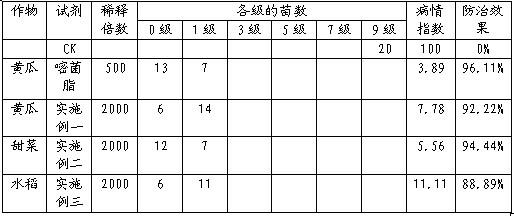

Examples

Embodiment 1

[0031] A wettable powder prepared by:

[0032] 1. Liquid fermentation culture

[0033] ①Strain activation

[0034] After the strain was taken out from the -70°C refrigerator, it was activated and cultured through 3 transfers, and the medium was liquid seed medium PSA;

[0035] ②Preparation of seed solution

[0036] Pick a single colony and culture it in a new liquid seed medium PSA at 28°C and 180rpm for 15 hours;

[0037] ③ Inoculate the cultured liquid bacteria into the liquid medium at an inoculation amount of 0.5%;

[0038] ④ 200rpm, cultured at 20°C for 3 days;

[0039] ⑤ The fermented liquid obtained through step ④ is fermented and cultivated to obtain mother powder by drying, then adding carrier fillers, auxiliary agents, stabilizers and protective agents in proportion, and crushing to obtain the preparation;

[0040] The formula of the liquid medium is: by weight percentage, maltose 0.2%; corn flour, 0.5%; soybean flour, 0.4%; tryptone, 0.5%; CaCl 2 , 0.02%; MnSO...

Embodiment 2

[0047] A wettable powder prepared by:

[0048] 1. Liquid fermentation culture

[0049] ①Strain activation

[0050] After the strain was taken out from the -70°C refrigerator, it was activated and cultured through 3 transfers, and the medium was liquid seed medium LB;

[0051] ②Preparation of seed solution

[0052] Pick a single colony and culture it in a new liquid seed medium LB at 30°C and 200rpm for 18 hours;

[0053] ③Inoculate the cultured liquid bacteria into the liquid culture medium according to the inoculum amount of 2%;

[0054] ④ 230rpm, cultured at 25°C for 2 days;

[0055] ⑤ The fermented liquid obtained through step ④ is fermented and cultivated to obtain mother powder by drying, and then adding carrier fillers, auxiliary agents, stabilizers and protective agents in proportion and pulverizing to obtain the preparation;

[0056]The formula of the liquid medium is: by weight percentage, maltose 0.3%; corn flour, 0.6%; soybean flour, 0.6%; tryptone, 0.8%; CaCl ...

Embodiment 3

[0063] A wettable powder prepared by:

[0064] 1. Liquid fermentation culture

[0065] ①Strain activation

[0066] After the strain was taken out from the -70°C refrigerator, it was activated and cultured through 3 transfers, and the medium was liquid seed medium PSA;

[0067] ②Preparation of seed solution

[0068] Pick a single colony and culture it in a new liquid seed medium PSA at 35°C and 220rpm for 20 hours;

[0069] ③ Inoculate the cultured liquid bacteria into the liquid culture medium at an inoculum volume of 4%;

[0070] ④ 250rpm, culture at 30°C for 1 day;

[0071] ⑤ The fermented liquid obtained through step ④ is fermented and cultivated to obtain mother powder by drying, and then adding carrier fillers, auxiliary agents, stabilizers and protective agents in proportion and pulverizing to obtain the preparation;

[0072] The formula of the liquid medium is: by weight percentage, maltose 0.4%; corn flour, 0.8%; soybean flour, 0.9%; tryptone, 1.0%; CaCl 2 , 0.08...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com