Method for preparing soft magnetic mesoporous nickel-zinc ferrite microspheres

A technology of nickel-zinc ferrite and microspheres, which is applied in the field of preparation of mesoporous magnetic microspheres, can solve the problems of difficult particle size, shape and structure, high requirements for reaction conditions, low reproducibility, etc. Low cost, high safety factor, and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

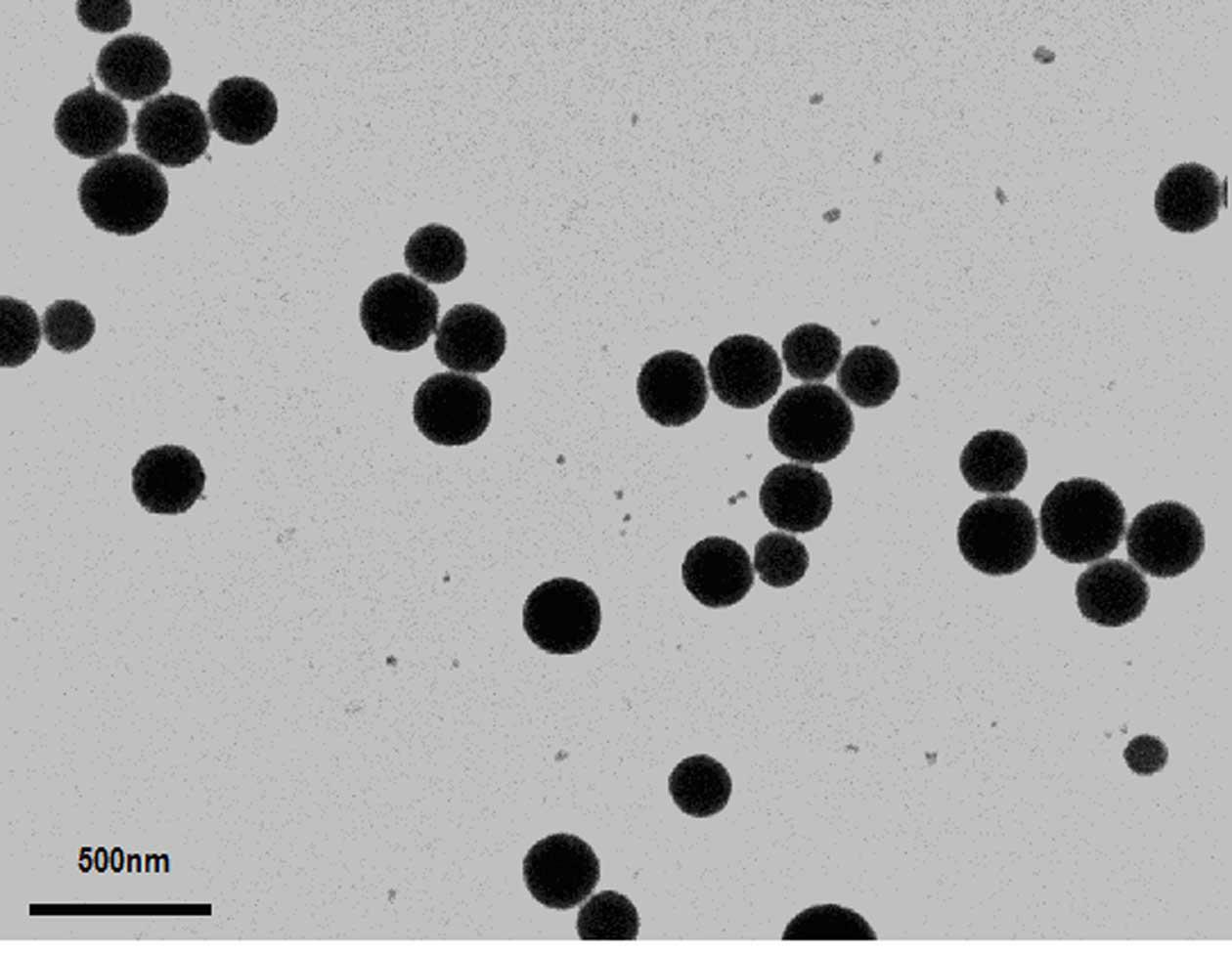

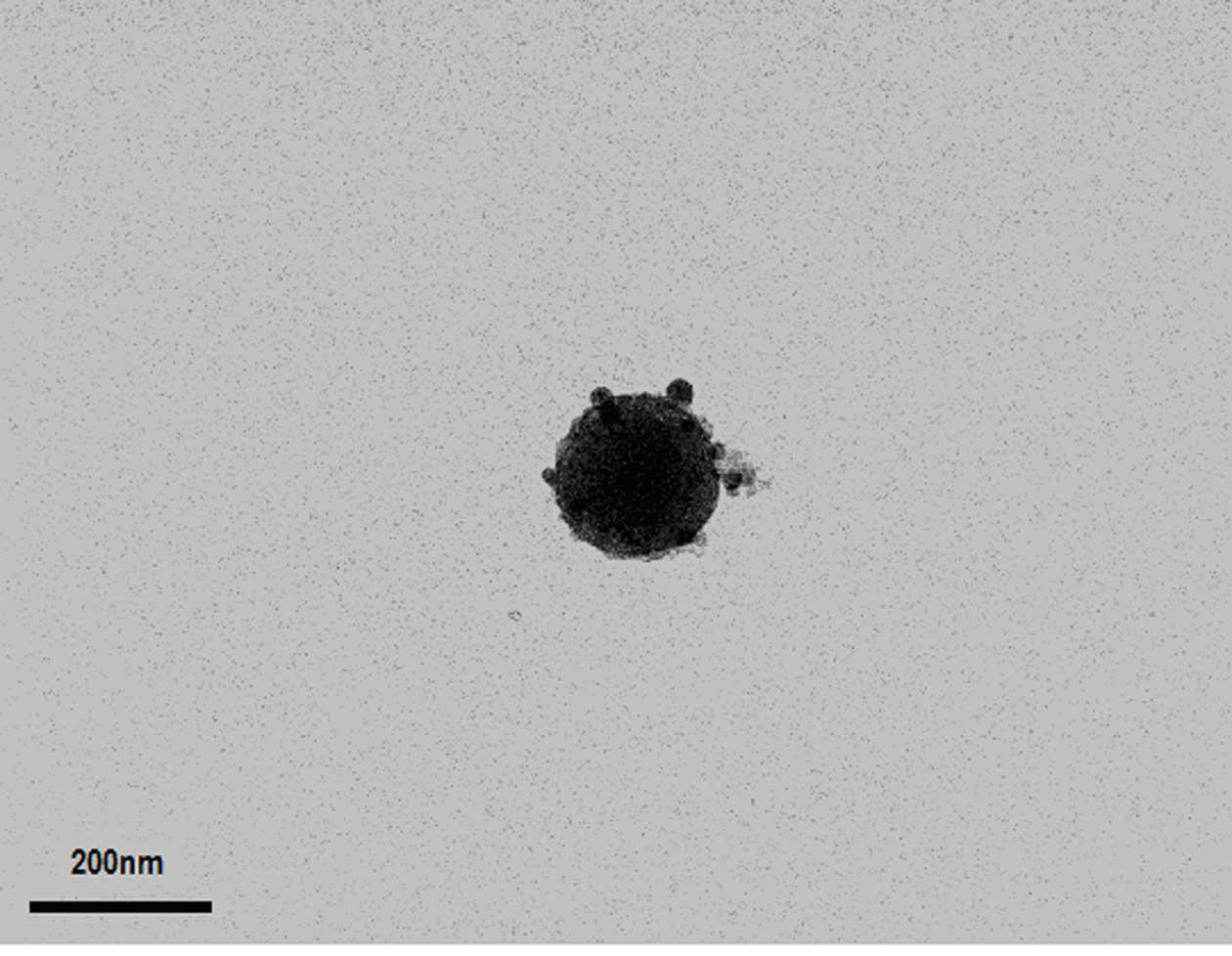

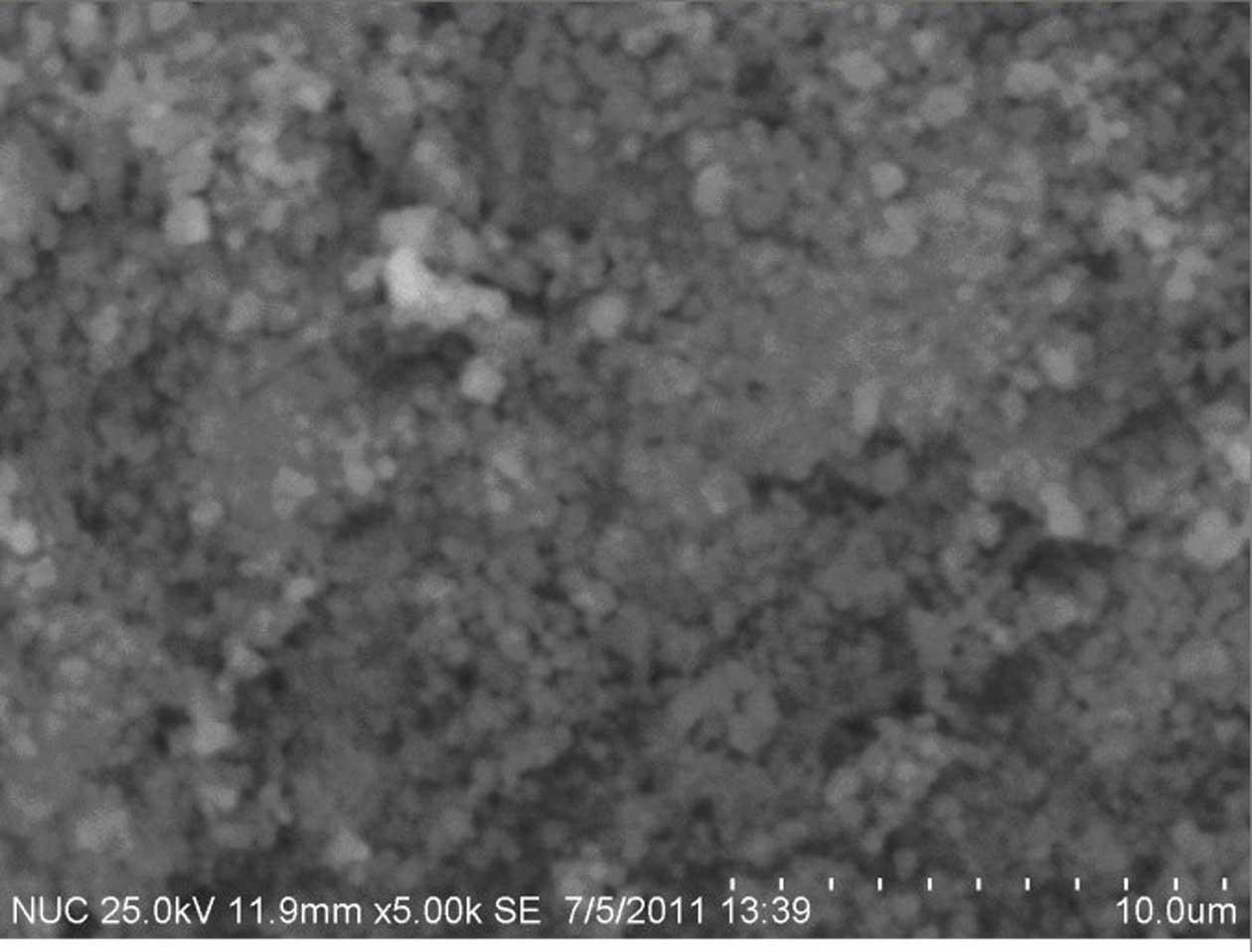

Image

Examples

Embodiment 1

[0035] A method for preparing soft magnetic mesoporous nickel-zinc ferrite microspheres, comprising the steps of:

[0036] (1) Dissolve glucose in deionized water to prepare a glucose solution with a mass concentration of 0.1g / ml, transfer the prepared glucose solution to a high-pressure reactor, and conduct a hydrothermal reaction at 180°C for 8 hours, and then transfer to In a high-speed centrifuge, and at a speed of 16000rpm, separate for 10min to obtain solid C microspheres;

[0037] (2) Take NiCl 2 ·6H 2 O, ZnCl 2 ·6H 2 O and FeCl 3 ·6H 2 O and be dissolved in ethylene glycol together, fully stir 40min, then add ammonium acetate, fully stir again 30min, finally obtained orange cloudy liquid, the molar concentration ratio of metal salt ion in this orange cloudy liquid is Ni 2+ :Zn 2+ :Fe 3+ =1:1:4, the amount of ammonium acetate added is 0.05g / ml;

[0038] (3) Take the C microspheres obtained in step (1) and dissolve them in the orange turbid solution obtained in ...

Embodiment 2

[0050] A method for preparing soft magnetic mesoporous nickel-zinc ferrite microspheres, comprising the steps of:

[0051] (1) Dissolve glucose in deionized water to prepare a glucose solution with a mass concentration of 0.05g / ml, transfer the prepared glucose solution into a high-pressure reactor, and conduct a hydrothermal reaction at 190°C for 10 hours, and then transfer to In a high-speed centrifuge, and separated at a speed of 16,000rpm for 5min, the solid C microspheres were finally obtained;

[0052] (2) Take NiCl 2 ·6H 2 O, ZnCl 2 ·6H 2 O and FeCl 3 ·6H 2 O and be dissolved in ethylene glycol together, fully stir 30min, then add ammonium acetate again, fully stir 35min again, finally obtained orange cloudy liquid, the molar concentration ratio of metal salt ion in this orange cloudy liquid is Ni 2+ :Zn 2+ :Fe 3+ =1:1:4, the amount of ammonium acetate added is 0.025g / ml;

[0053] (3) Take the C microspheres obtained in step (1) and dissolve them in the orange ...

Embodiment 3

[0061] A method for preparing soft magnetic mesoporous nickel-zinc ferrite microspheres, comprising the steps of:

[0062] (1) Dissolve glucose in deionized water to prepare a glucose solution with a mass concentration of 0.15g / ml, transfer the prepared glucose solution to a high-pressure reactor, and conduct a hydrothermal reaction at 200°C for 12 hours, and then transfer to In a high-speed centrifuge, and at a speed of 17,000 rpm, separate for 8 minutes to obtain solid C microspheres;

[0063] (2) Take NiCl 2 ·6H 2 O, ZnCl 2 ·6H 2 O and FeCl 3 ·6H 2 O and be dissolved in ethylene glycol together, fully stir 35min, then add ammonium acetate, fully stir again 40min, finally obtained orange cloudy liquid, the molar concentration ratio of metal salt ion in this orange cloudy liquid is Ni 2+ :Zn 2+ :Fe 3+ =1:1:4, the amount of ammonium acetate added is 0.01g / ml;

[0064] (3) Take the C microspheres obtained in step (1), and dissolve them in the orange turbid solution obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com