Preparation method of toothpaste abrasive silicon dioxide

A silicon dioxide, pure silicon dioxide technology, applied in the direction of silicon dioxide, silicon oxide, cosmetic preparations, etc., can solve the problems of high abrasiveness and transparency effects, and achieve moderate abrasiveness, good transparency, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Prepare 500g of sodium silicate solution with a weight percent of silicon dioxide of 12%, at a temperature of 40°C

[0016] Add 210g of 20% (weight) sulfuric acid solution, react for 2 hours, adjust the pH value to 3-4 with 20% (weight) sulfuric acid; add 0.6g of ethylene glycol, heat up to 70°C and keep for 2 hours;

[0017] Then wash with water, and use a high-speed disperser at 2700 rpm to beat and disperse the filter cake for 1 hour; flash dry and pulverize to a particle size of 8-10 microns to obtain toothpaste abrasive silica;

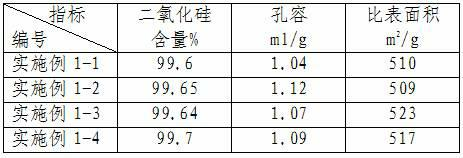

[0018] Its physical and chemical properties are as follows

[0019] Embodiment 1: Physicochemical property table of toothpaste friction agent silicon dioxide

[0020]

Embodiment 2

[0022] Prepare 500g of sodium silicate solution with a silicon dioxide content of 15% (weight), add 515g of 10% sulfuric acid (weight) solution at a temperature of 50°C, react for 4 hours, and adjust the pH value to 3-4 with sulfuric acid , add 1.5g of sorbitol, raise the temperature to 80°C, and keep it warm for one hour; then filter, wash with water, and use a high-speed disperser at 2600 rpm to beat and disperse the filter cake for 1 hour; use flash drying and pulverization to obtain Toothpaste abrasive silica with an average particle size of 9-10 microns. Its experimental data are as follows.

[0023] Embodiment 2: Physicochemical property table of toothpaste friction agent silicon dioxide

[0024]

Embodiment 3

[0026] Formulated with a silica content of 13

[0027] % (weight) sodium silicate solution 500g, add and prepare 15% sulfuric acid (weight) solution 303g at a temperature of 50°C, react for 3 hours, adjust the pH value to 4-5 with sulfuric acid, add 1.5g of pentaerythritol, and heat up to 80°C, keep warm for one hour; then filter, wash with water, and use a high-speed disperser at 2400 rpm to beat and disperse the filter cake for 1.5 hours; use

[0028] Flash drying and pulverization obtain toothpaste abrasive silicon dioxide with an average particle size of 8-10 microns. Its experimental data are as follows.

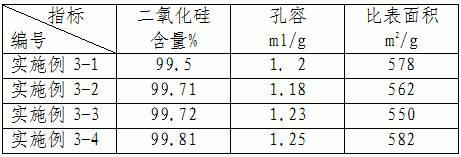

[0029] Embodiment 3: Table of physical and chemical properties of silicon dioxide, abrasive agent for toothpaste

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com