Silicon tetrachloride purification method and apparatus thereof

A technology for purifying silicon tetrachloride and polytetrafluoroethylene, applied in the direction of halogenated silicon compounds, halogenated silanes, etc., can solve the problems of large equipment investment, large photon transmission loss, complex process, etc., to reduce height and increase contact Large area, strong anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: rectification packed tower

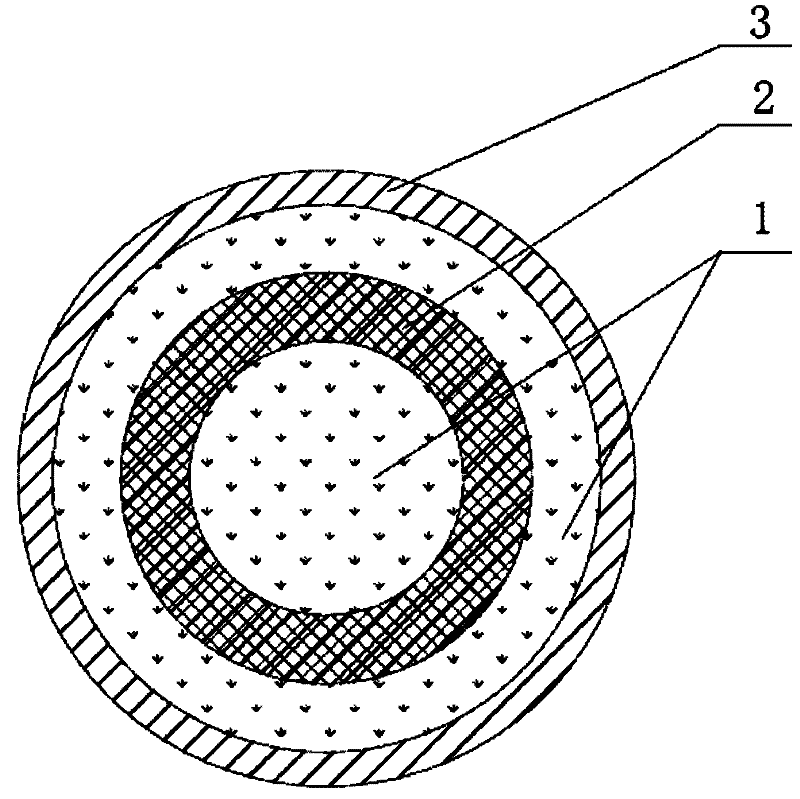

[0025] see figure 1 . The height of the packed tower is 8.6m, of which the packing part is 6m high and 0.76m in diameter, and the tower shell is made of 316L stainless steel. The rectification tower includes a tower shell, light radiation air cooler packing, packing support device and heating device (0.7m in height, 0.4m in diameter). Cylindrical packing is evenly placed upright on the packing support device in the tower, and each layer of packing support device Put 500 cylindrical fillers on top, the fillers are made of poly-p-phenylene terephthalamide fibers, polytetrafluoroethylene, and 316L steel. formamide fiber and polytetrafluoroethylene. The outer diameter of the outer shell of the cylindrical filler is 3mm, and a hollow polytetrafluoroethylene cylinder is coaxially placed inside. The wall thickness of the cylinder is 0.4mm, and the inner diameter is 1.5mm. The middle and outer sides of the cylinder are filled with p...

Embodiment 2

[0028] The raw material is crude silicon tetrachloride separated from the by-products of polysilicon production, the purity of which is 99.5%, and it is purified by rectification. The incoming material first passes through the silica gel adsorption column, and then enters the rectification tower. After 8 hours of total reflux, the temperature at the top of the tower is controlled to reach 53-55°C, and when the temperature of the tower kettle reaches 60-65°C, the material starts to be discharged. The reflux ratio is 20:1, and the intermediate product obtained from the middle outlet is the obtained high Pure tetrachlorosilicon product, packaged after condensation. Impurities such as trichlorosilane produced by rectification are discharged from the tail gas outlet.

[0029] In the product, the purity of silicon tetrachloride reaches ppb level, and the impurity content is: W Cr = 0.05ppb; W Fe = 2ppb; W co = 0.1ppb; W cu = 0.1ppb; W Mn = 0.02ppb; W Ni = 1.5ppb; W V = 0.5pp...

Embodiment 3

[0032]The raw material is crude silicon tetrachloride separated from the by-products of polycrystalline production, the purity of which is 99.4%, and it is purified by rectification. The incoming material first passes through the silica gel adsorption column, and then enters the rectification tower. After 9 hours of full reflux, the temperature at the top of the tower is controlled to reach 51-52°C, and when the temperature of the tower kettle reaches 65-70°C, the material starts to be discharged. The reflux ratio is 30:1, and the intermediate product obtained from the middle outlet is the obtained high Pure tetrachlorosilicon product, packaged after condensation. Impurities such as trichlorosilane produced by rectification are discharged from the tail gas outlet.

[0033] In the product, the purity of silicon tetrachloride reaches ppb level, and the impurity content in it is: W Cr = 0.08ppb; W Fe = 3ppb; W co = 0.4ppb; W cu = 0.6ppb; W Mn = 0.06ppb; W Ni = 1.6ppb; W V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com