Large-caliber solar plastic lens splicing die

A plastic lens and mould-joining technology, which is applied to home appliances, other home appliances, optical components, etc., can solve the problems of difficult production and processing of large-diameter solar plastic lens molds, and achieve the effect of flexible manufacturing and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

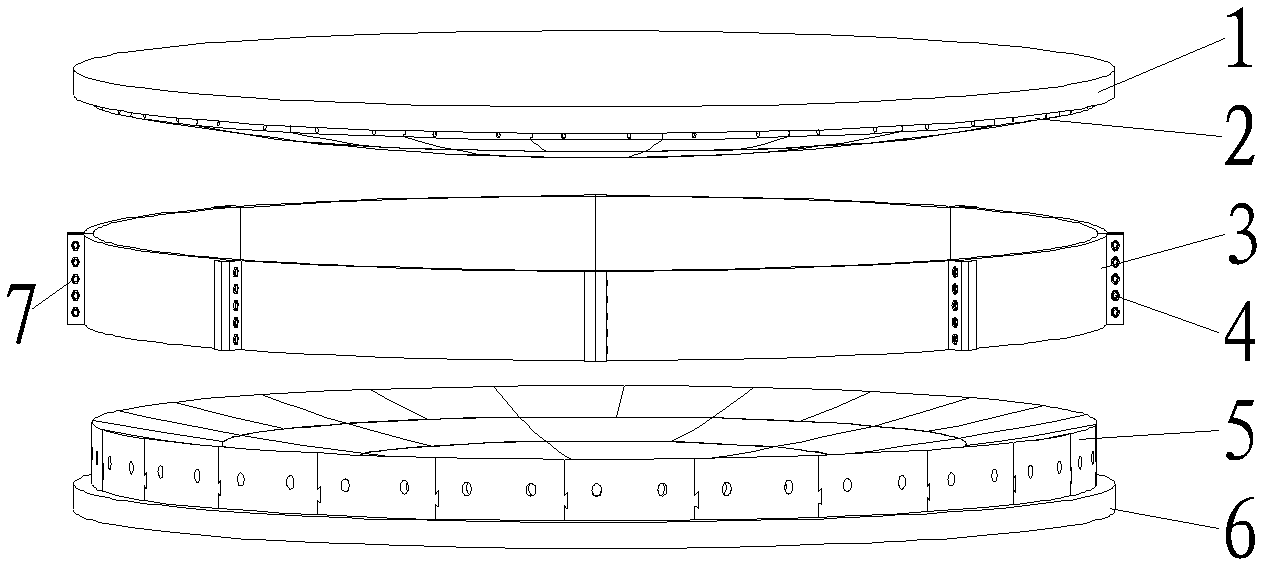

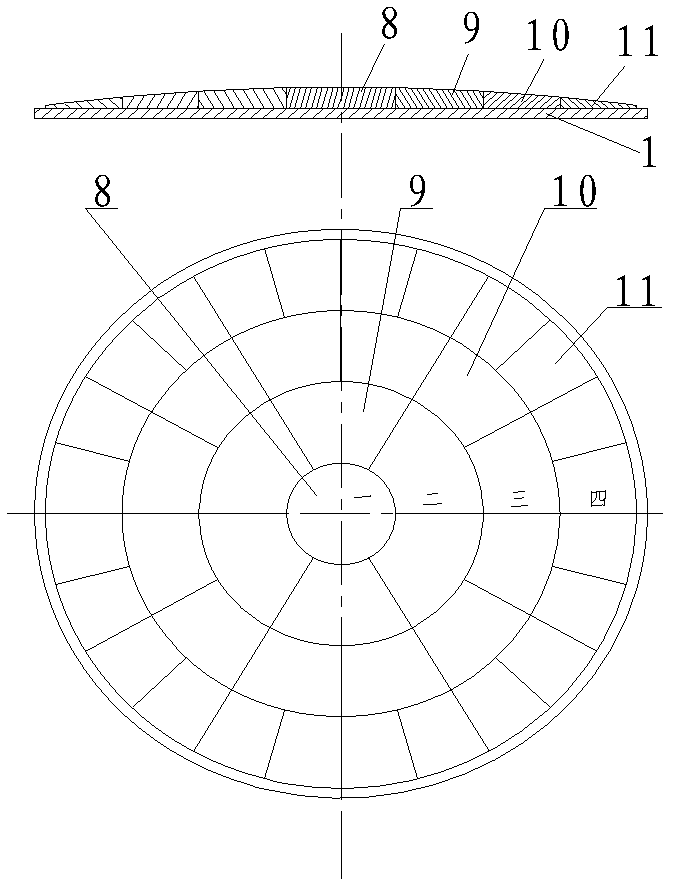

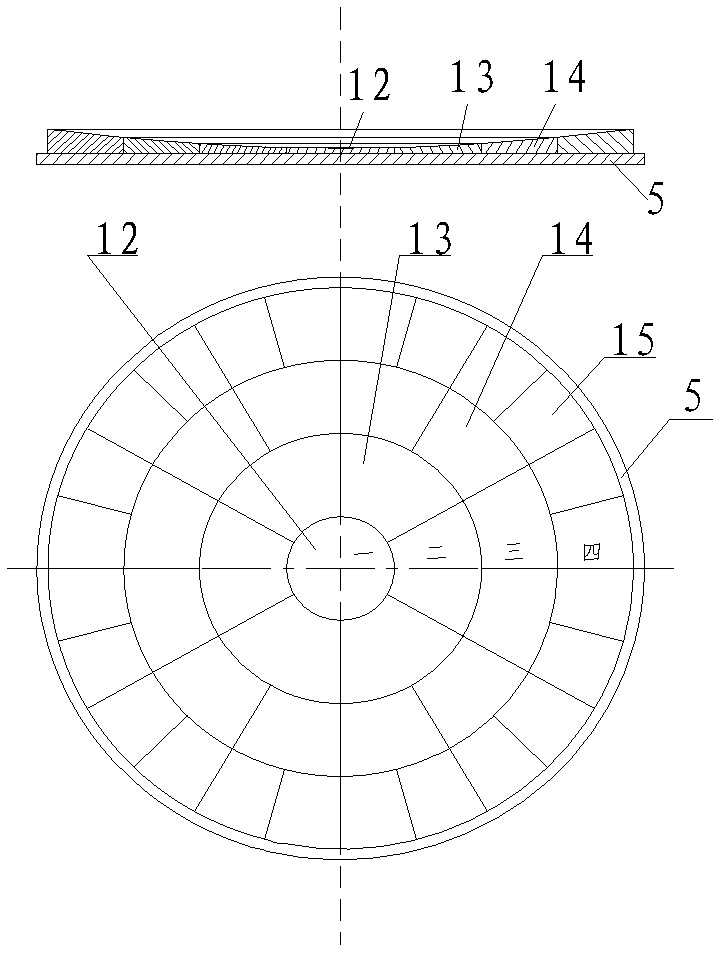

[0027] Such as Figure 1-11 As shown, the embodiment of the present invention is provided with punch base 1, punch mold 2, side mold 3, die mold 5, die base 6, hexagon socket bolt 4, nut 7; Wherein, punch mold 2 is made of From the inside to the outside, there are one-level punch die block 8, two-stage punch die block 9, three-stage punch die block 10 and four-stage punch die block 11; Part or all of the sub-mold blocks in the second-level concave mold sub-mold block 13, the third-level concave mold sub-mold block 14, and the fourth-level concave mold sub-mold block 15 are spliced. The punch base 1 and the die base 6 are fixed on the injection molding platform, the first-level die sub-mold block 12, the second-level die sub-mold block 13, the third-level die sub-mold block 14, and the fourth-level die sub-mold The block 15 is spliced and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com