Diamond cutter slow-feeding and fast-retracting device based on air static pressure guide rail component

A technology of diamond tools and aerostatic pressure, which is used in grinding drive devices, parts of grinding machine tools, manufacturing tools, etc. problem, to achieve the effect of simple and accurate slow forward and fast backward operation, self-locking, high-precision repeated positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

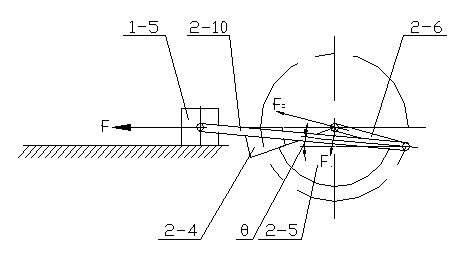

[0022] Specific implementation mode one: as Figure 1-Figure 9 , a diamond tool slow-forward and fast-reverse device based on an aerostatic guideway component, the device includes an aerostatic guideway component 1, a slow-forward and fast-reverse component 2, and a machine tool base 3,

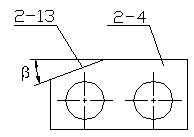

[0023]The slow-forward and fast-rewind part 2 includes an operating hand wheel 2-1, an extension rod 2-2, a bearing support seat 2-3 with a built-in diagonal contact bearing, a limit block 2-4, a sector block 2-5, a short Connecting rod 2-6, guide rail connector 2-7, first bearing 2-9, long connecting rod 2-10, second bearing 2-11; aerostatic guide rail part 1 and slow forward and fast rewind part 2 all set On the upper surface of the machine tool base 3, the middle part of the upper surface of the machine tool base 3 is provided with a through long groove 3-1 along its width direction, and the left side of the machine tool base 3 near the front end of the left side is along the The length d...

specific Embodiment approach 2

[0026] Specific implementation mode two: as figure 1 , image 3 and Figure 6a-Figure 6c , Specific Embodiment 1 A diamond cutter slow-forward and fast-reverse device based on aerostatic guideway components, the aerostatic guideway component 1 includes slide plates 1-5, four thrust plates and a plurality of small Orifice restrictor 1-4, four thrust plates are left side thrust plate 1-1, right side thrust plate 1-7, left upper thrust plate 1-3 and right upper thrust plate 1-6, slide The plate 1-5 is located in the middle of the upper surface of the machine base 3, the left side of the slide plate 1-5 is integrally formed with a left boss 1-9, and the right side of the slide plate 1-5 is integrally formed with a right boss 1 -10, the left thrust plate 1-1 is located on the left side of the left boss 1-9, the right thrust plate 1-7 is located on the right side of the right boss 1-10, and the left upper thrust plate 1-3 is placed on On the left side thrust plate 1-1 and the lef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com