Novel automatic gantry welding machine

An automatic and gantry technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of inability to adapt to large-scale, continuous and uninterrupted welding operations, poor equipment integration, and low production efficiency, and achieve improved welding. Work efficiency, ensure welding quality, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

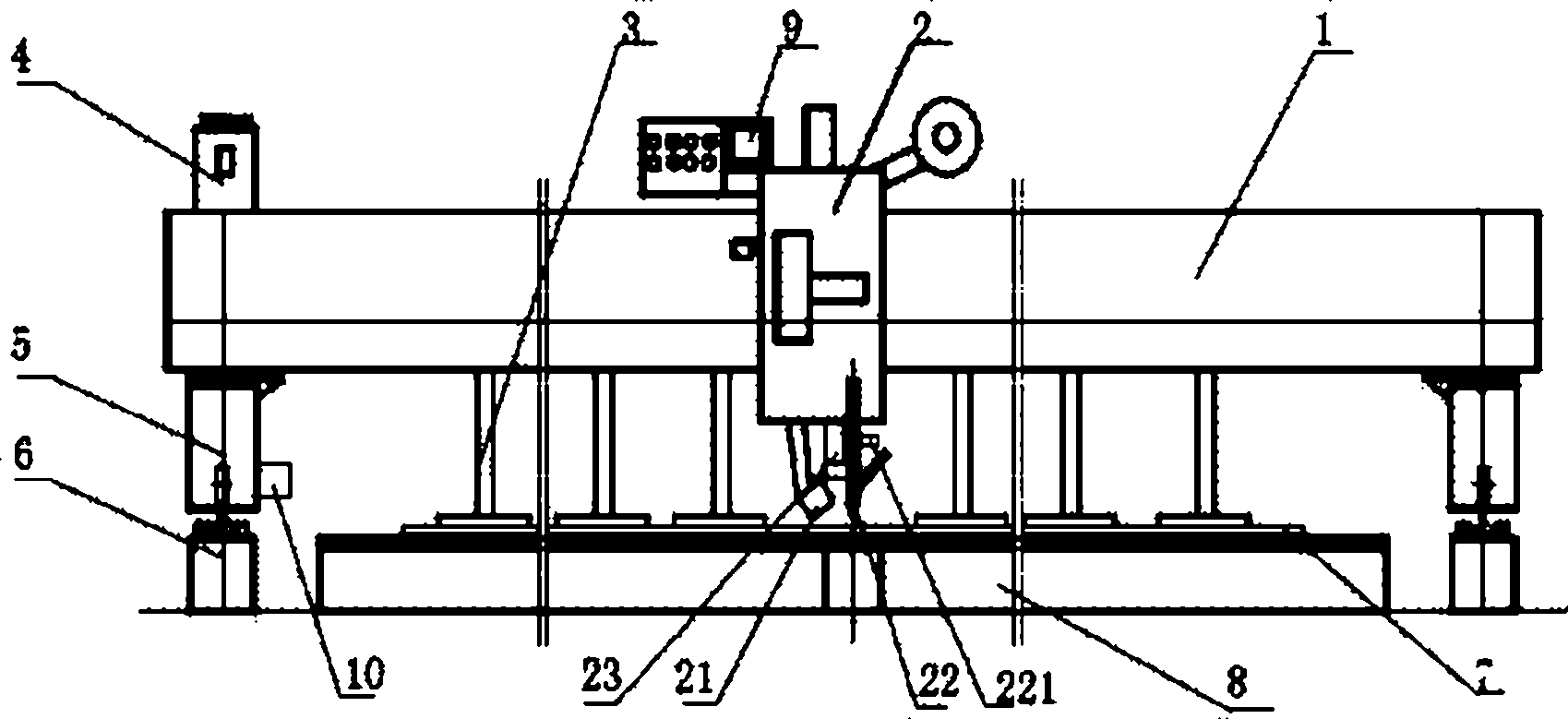

[0019] Such as figure 1 and figure 2 As described, the present invention includes a gantry 1, a welding head 2, a welding wire delivery device 21 and a welding torch 22, a hydraulic pressing device 3, a hydraulic station 4, a traveling mechanism 5, and a track assembly 6 are installed on the welding head 2, and also includes Install adjustment and work platform system 8, install adjustment and work platform system 8 and include left work platform 81, right work platform 82, be fixed welding support beam 7 in the middle of left work platform 81 and right work platform 82, on left work platform 81 and the bottom of right working platform 82 are provided with hydraulic lifting device 84. An infrared centering device 10 can also be provided on one side of the traveling mechanism 5, an infrared correction device 221 can also be installed on the gun body of the welding torch 22, and the welding head 2 also includes a control operation instrument 9 that can be used to control the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com