Automatic material distributing and conveying device of cold-drawn steel tubes

A feeding device and technology for steel pipes, applied in the field of equipment for conveying raw material pipes for cold-drawn steel pipe production lines, can solve the problems of low automation, harsh operating environment, and high labor intensity, and achieve high automation, good operating environment, and low labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

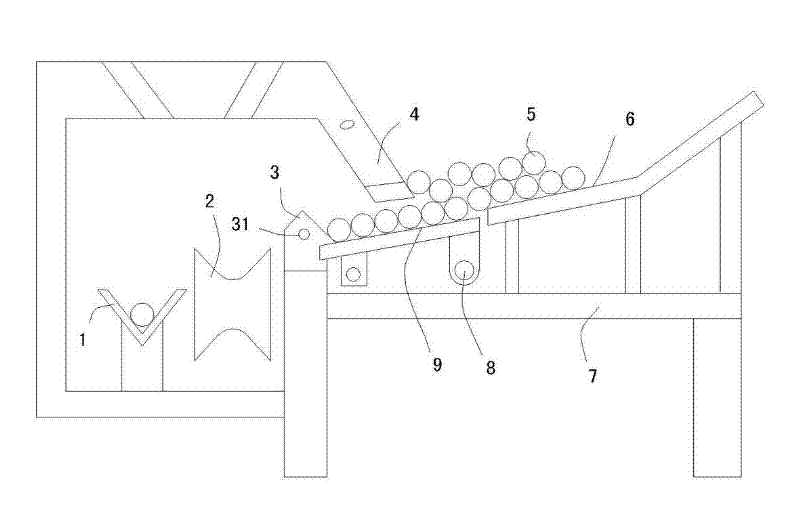

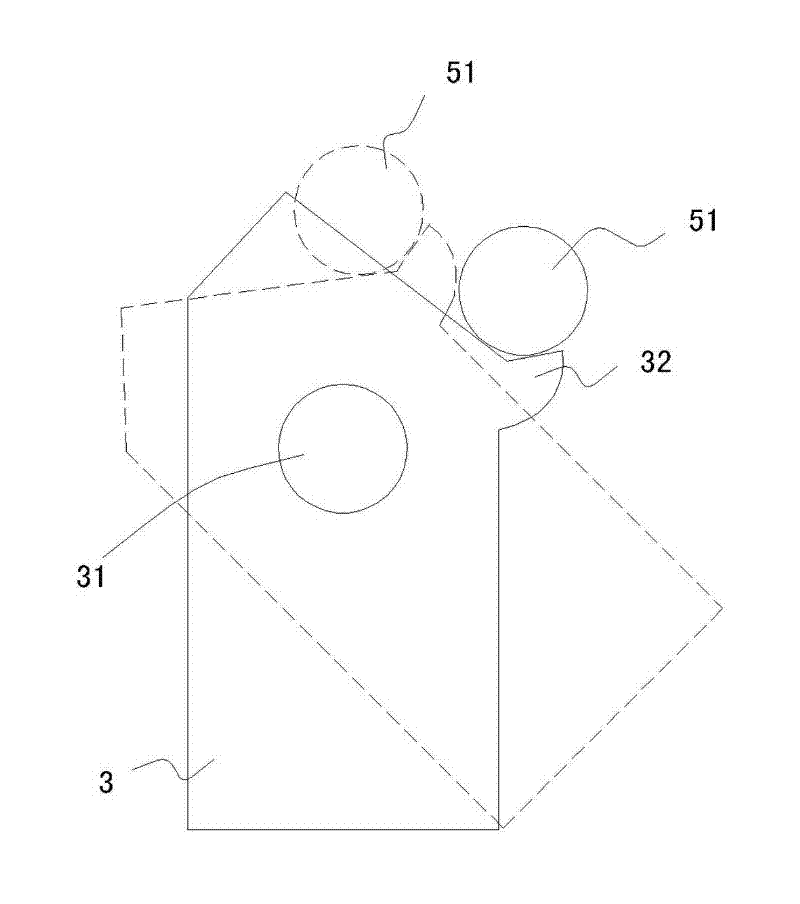

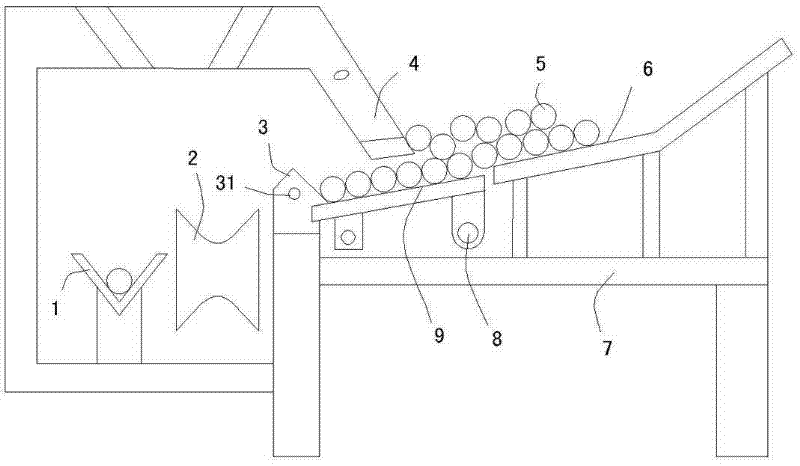

[0012] see figure 1 , and combined with figure 2 . This cold-drawn steel pipe automatic distributing and feeding device is composed of a frame 7, a vertical turning device 3 and an axial feeding device. The top of the frame 7 is a fixed inclined surface 6, which is used to preset the source steel pipe 5. The horizontal inclination angle of the fixed inclined surface 6 is preferably 10 degrees, so that a suitable self-gravity component can be obtained. The vibrating inclined surface 9 is fixed separately via the fixed shaft 8 and connected with the vibrating motor to obtain vibrating power. The horizontal inclination angle of the vibrating inclined surface 9 should be consistent with the fixed inclined surface 6, and be installed downstream of the fixed inclined surface 6.

[0013] The restrictor plate 4 is arranged above the entrance of the vibrating inclined surface 9, and the distance between its end and the vibrating inclined surface 9 should be slightly larger than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com