Fast mixing reactor and application thereof

A technology of mixing reactors and reactors, applied in fluid mixers, mixers, chemical/physical/physical-chemical stationary reactors, etc., can solve the problems of poor reaction effect, uniform mixing, and increased side reactions, etc. Achieve the effect of fast mixing, fast mixing and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

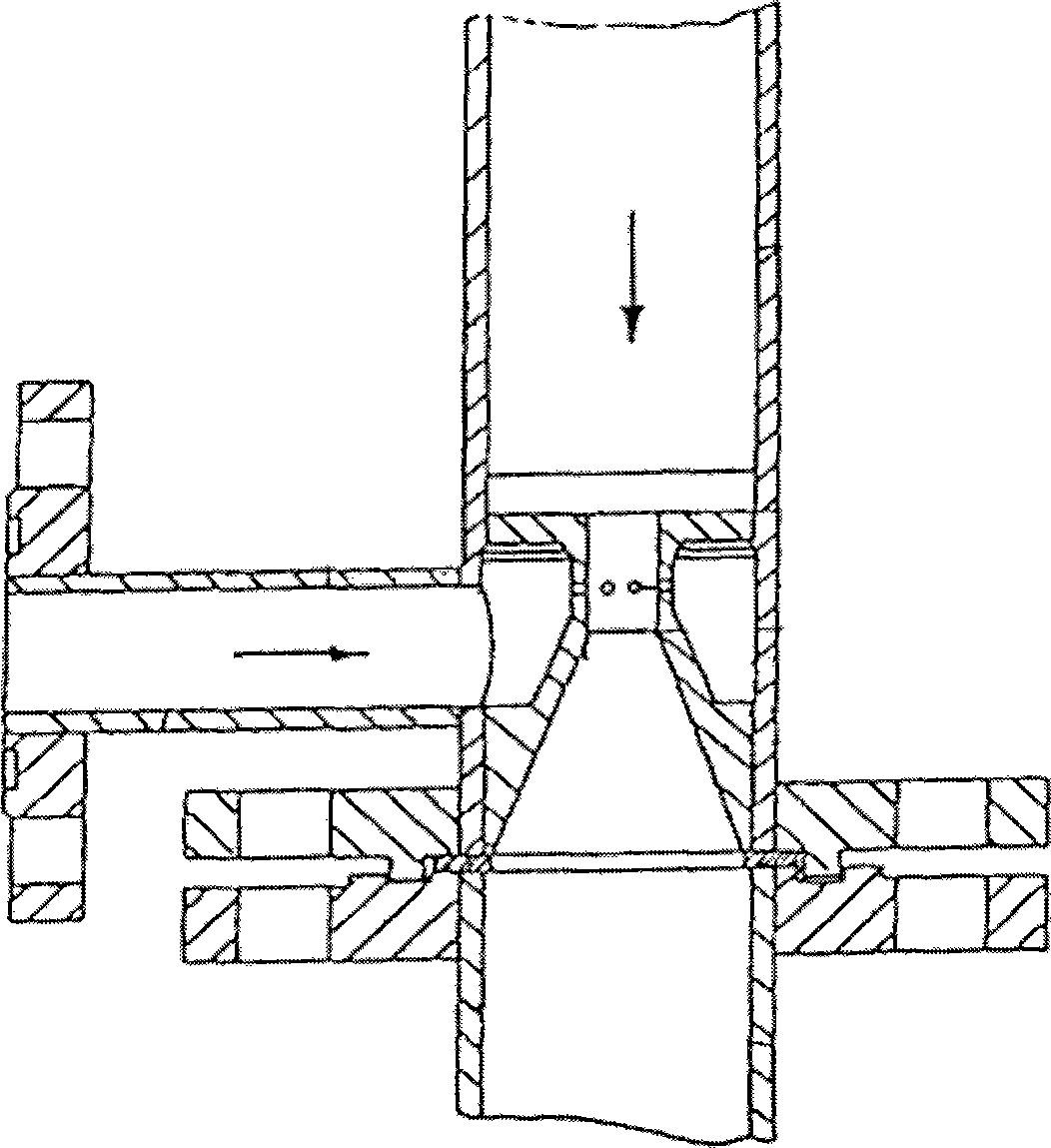

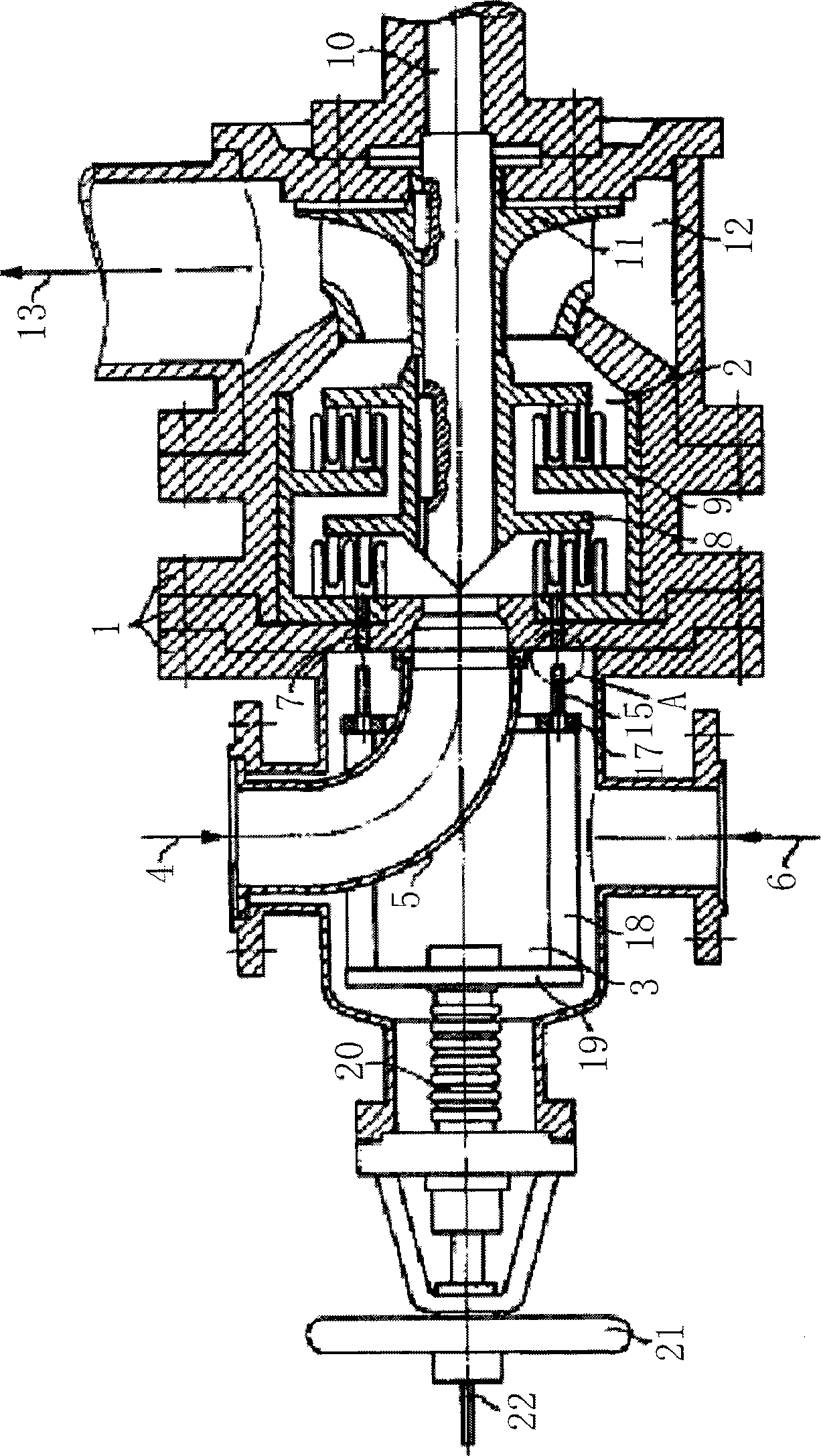

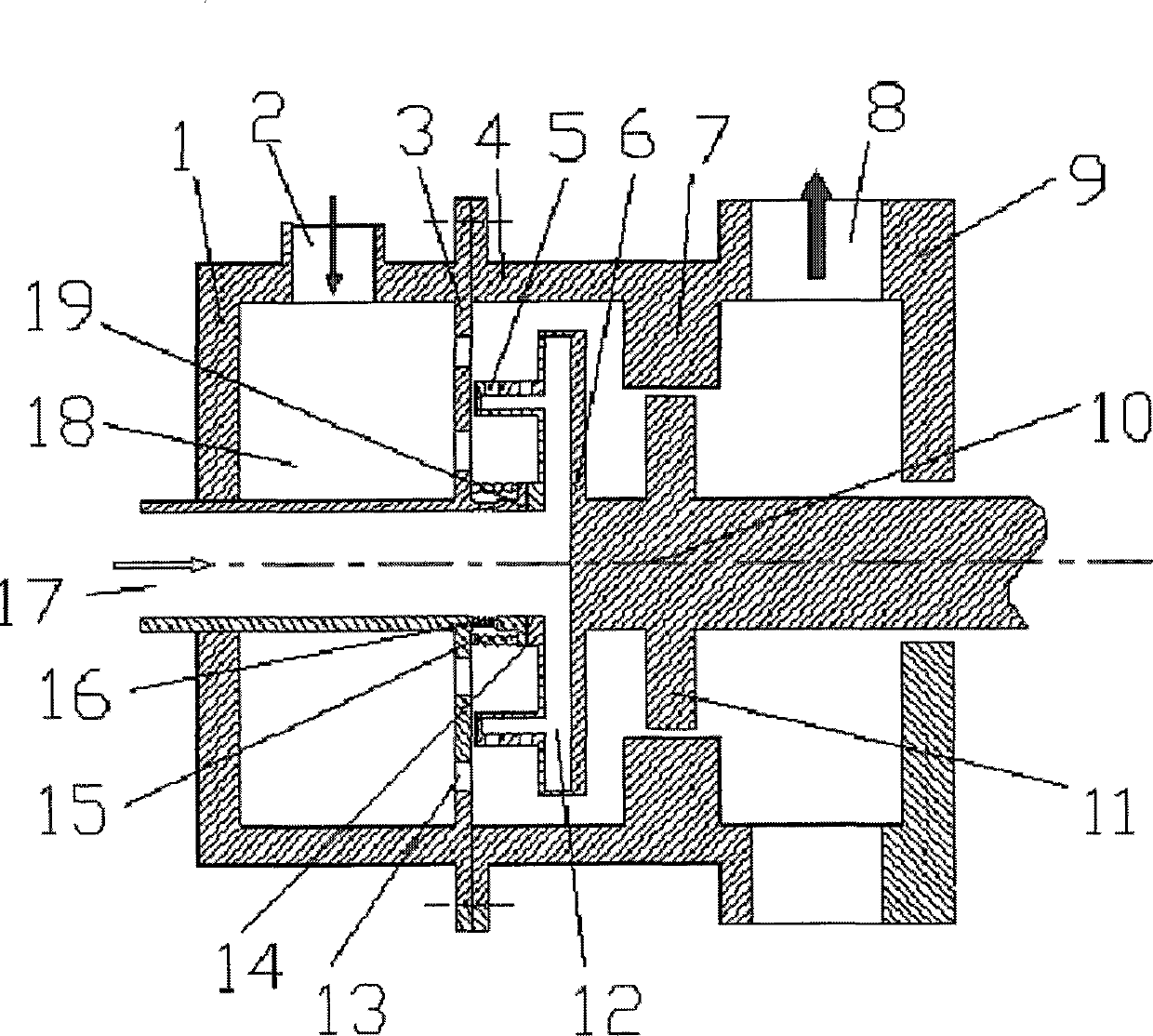

[0063] use image 3 The rapid mixing reactor shown was used for production trials of MDI. Among them, the first feed distributor such as Figure 6c As shown, some diameters are evenly distributed on the first feed distributor as circular channels of 20mm, and the outlet velocity of the phosgene solution through the first feed distributor circular channels is 6m / s; The opening method of the second feed injection port is as follows: Figure 5c As shown, the diameter of the opening is 10mm, the outlet velocity of the amine solution through the second feed injection port is 16m / s; the rotational speed of the rotating shaft is 1200rpm. The reactor is tested on the MDI device, the test load is 220,000 tons of MDI / year, the feed rate of the amine solution is 24t / h, chlorobenzene is used as the reaction solvent, and the mass concentration of the chlorobenzene solution of the amine is 33%. The chlorobenzene solution of amine is sprayed into the reactor shell through the rotating hol...

Embodiment 2

[0065] use image 3 The rapid mixing reactor shown was used for production trials of MDI. Among them, the first feed distributor such as Figure 6b As shown, arc-shaped slits with different inner diameters are uniformly distributed on the first feed distributor, and the radial width of the slits is 2 mm; the exit velocity of the phosgene solution passing through the arc-shaped slits is 10 m / s. The opening method of the second feed injection port on the hollow impeller material distributor is as follows: Figure 5b As shown, the injection port is a rectangle of 3mm×8mm; the exit velocity of the amine solution through the second feed injection port is 22m / s. The rotational speed of the rotating shaft was 1400 rpm. The reactor is tested on the MDI device, the test load is 300,000 tons of MDI / year, the feed rate of the amine solution is 33t / h, chlorobenzene is used as the reaction solvent, and the mass concentration of the chlorobenzene solution of the amine is 33%. The chloro...

Embodiment 3

[0068] use Figure 4 The rapid mixing reactor shown was tested for the production of polymethylene polyphenyl polyamines. Among them, the first feed distributor such as Figure 6b As shown, arc-shaped slits with different inner diameters are evenly distributed on the first feed distributor, and the radial width of the slits is 6 mm; the outlet velocity of the mixed solution of aniline hydrochloride and circulating fluid through the arc-shaped slit is 5m / s. The opening method of the second feed injection port on the hollow impeller material distributor is as follows: Figure 5b As shown, the injection port is a rectangle of 3mm×8mm; the exit velocity of the formaldehyde solution through the second feed injection port is 20m / s. The rotational speed of the rotating shaft was 2400 rpm. Adopt this reactor to test on the device of polymethylene polyphenyl polyamine, test load is 300,000 tons of polyamine / year, formaldehyde solution (mass fraction 37%) feed rate is 16t / h, formald...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com