Continuous production process and equipment for liquid detergent

A technology of liquid detergent and production process, applied in the direction of dissolving, mixing machines, chemical instruments and methods, etc., can solve the problems of washing water consumption, loss of materials, etc., and achieve the effect of saving power consumption and testing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

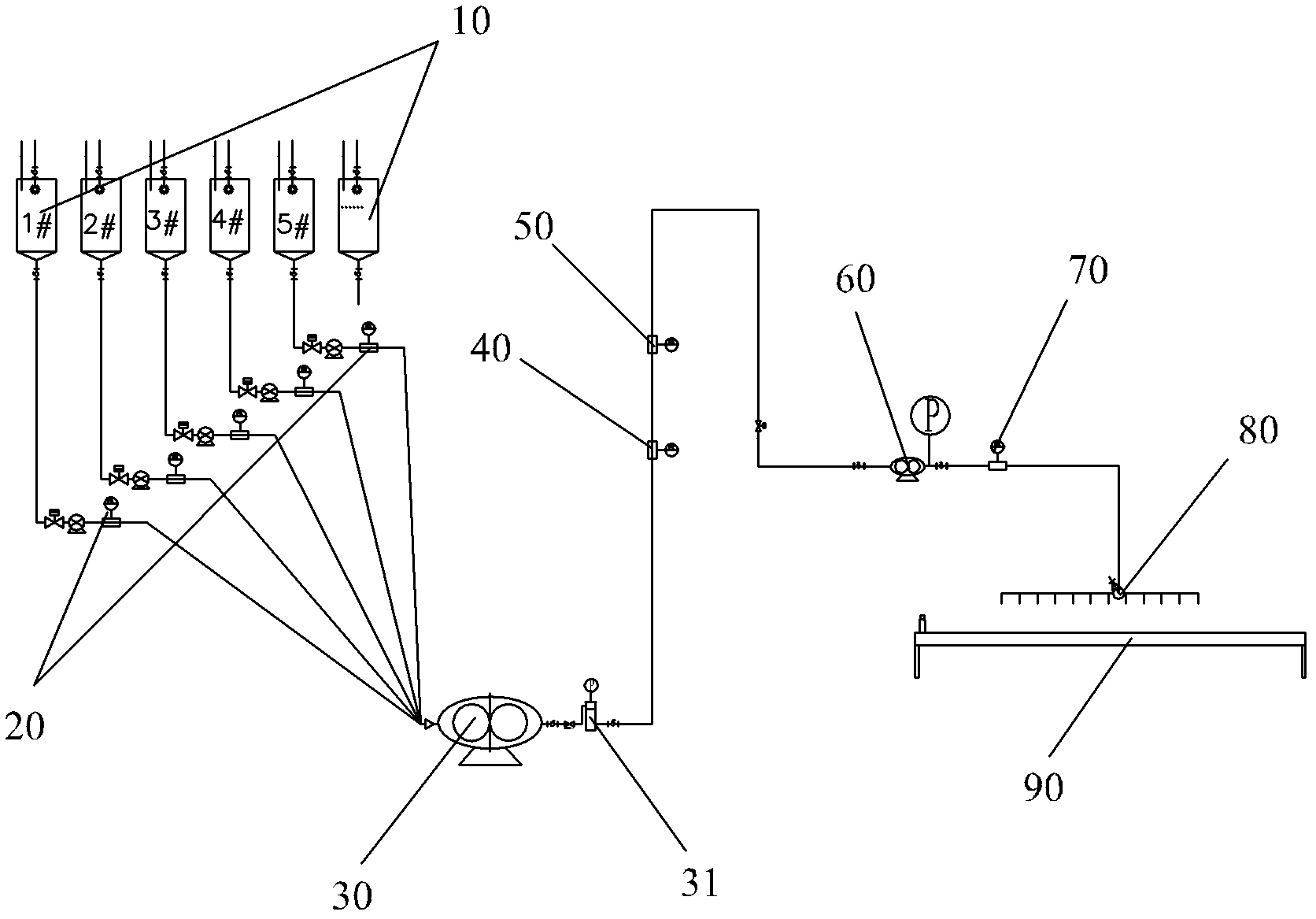

[0041] see figure 2 Shown is the structural diagram of the equipment required for the continuous production process of the liquid detergent of the present invention. The liquid raw material is directly transported to the raw material storage tank 10 for standby, and the solid raw material needs to be pre-dissolved in a suitable solvent and then transported to the raw material storage tank for standby. The raw materials of the liquid detergent are metered by the first mass flow meter 20 and continuously and quantitatively added to the dynamic mixer 30 according to a specific ratio. The pH value and viscosity of the raw material liquid are measured by an online pH meter 40 and an online viscometer 50 connected to the pipeline after the dynamic mixer 30 . The second mass flow meter 70 connected to the pipeline after the filling delivery pump 60 is connected to the filling working line 80 , and finally delivered by the delivery line 90 arranged below the filling working line 80 ...

Embodiment 2

[0054] (Continuous production process and equipment of dishwashing detergent products)

[0055] Taking dishwashing detergent products as an example, the operation process of applying the continuous production process of the present invention is shown in Table 1 below. Table 1 includes the normal production process and the switching process of two products on the production device.

[0056] Table 1 Table of two dishwashing detergent formulations

[0057]

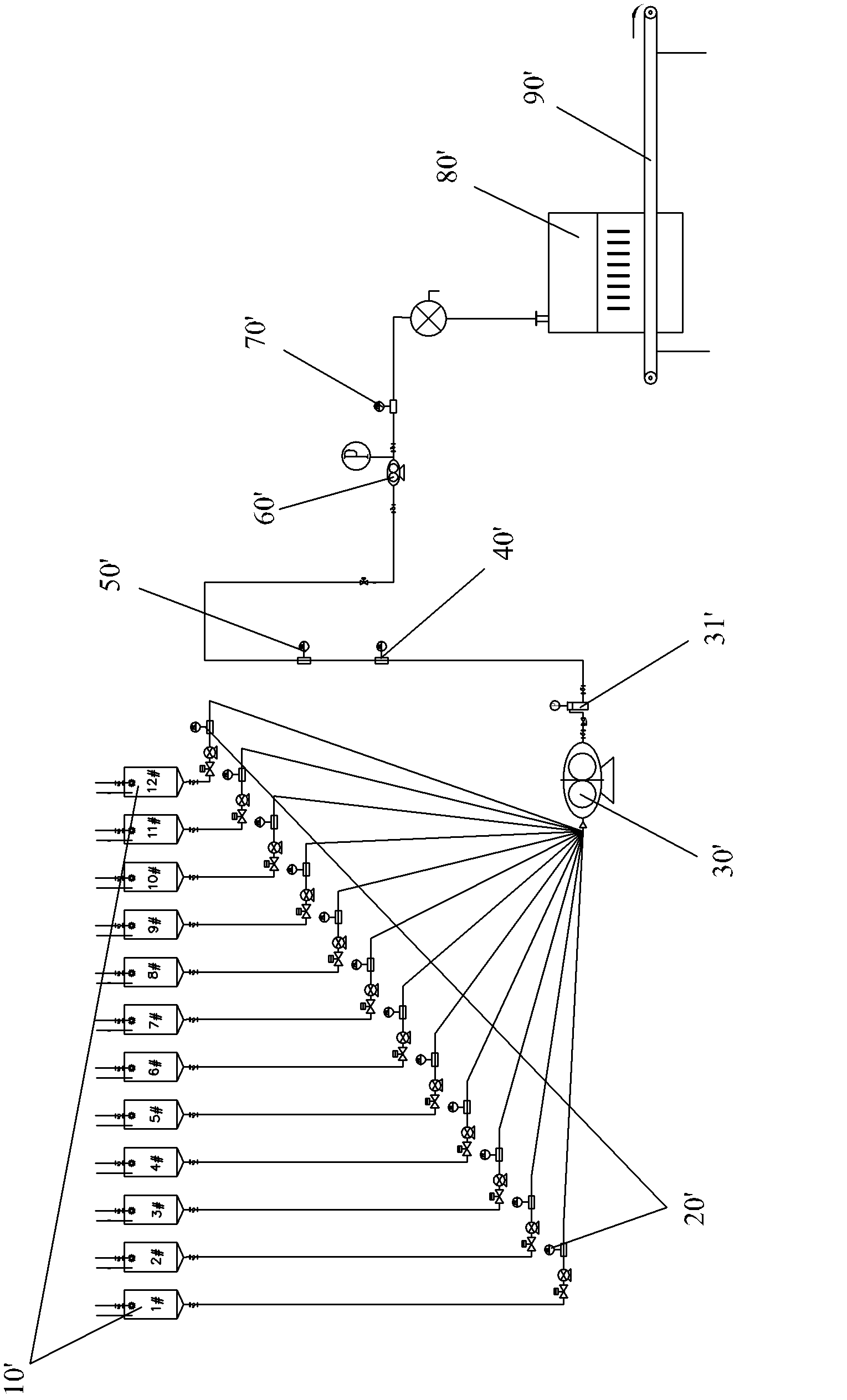

[0058] Such as image 3 Shown is the flow chart of the equipment required for the continuous production process of the present invention. The operating process of continuous production process production recipe one of the present invention can be expressed as follows:

[0059] Download recipe 1 from the operating terminal of the batching control system, and set recipe 1 as the active state. Open the feed pipe valves of 1#, 2#, 3#, 4#, 5#, 7#, 8#, 9#, 10#, 12# raw material storage tanks 10', close 6# and 11# raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com