Process for improving quality of phosphorus chemical industry waste smoke desulfurization gypsum

A technology for desulfurizing gypsum and waste flue gas, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problem of reducing the generation rate of new gypsum nuclei, increasing the driving force of crystal growth, and detecting errors prone to slurry, etc. problem, to achieve the effect of reducing the water content of gypsum, improving the quality of gypsum, and low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

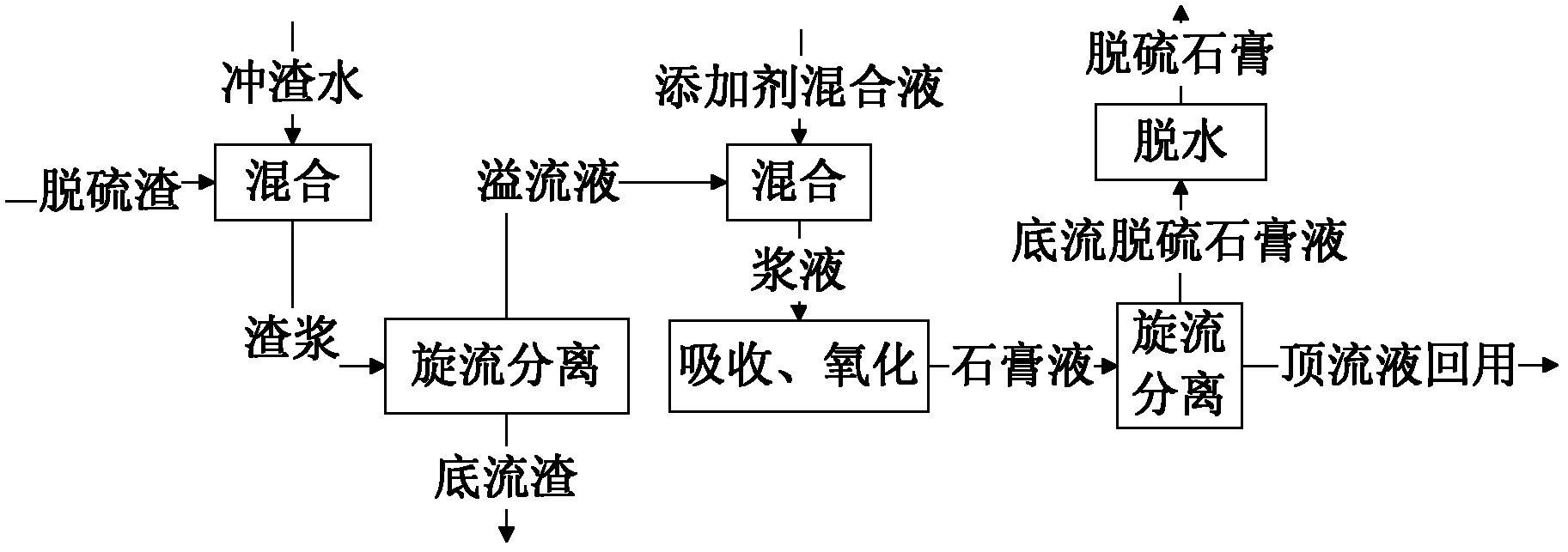

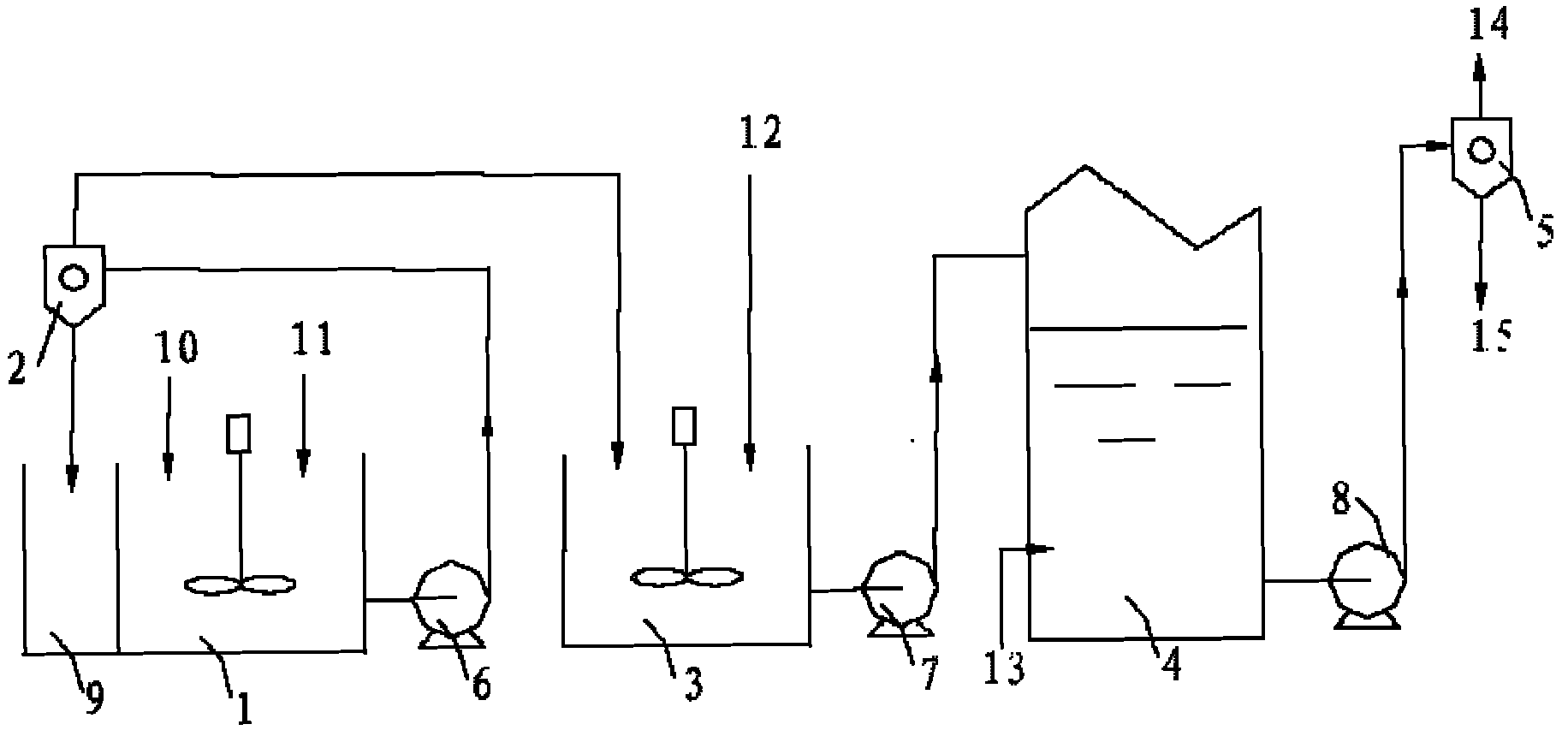

Method used

Image

Examples

Embodiment 1

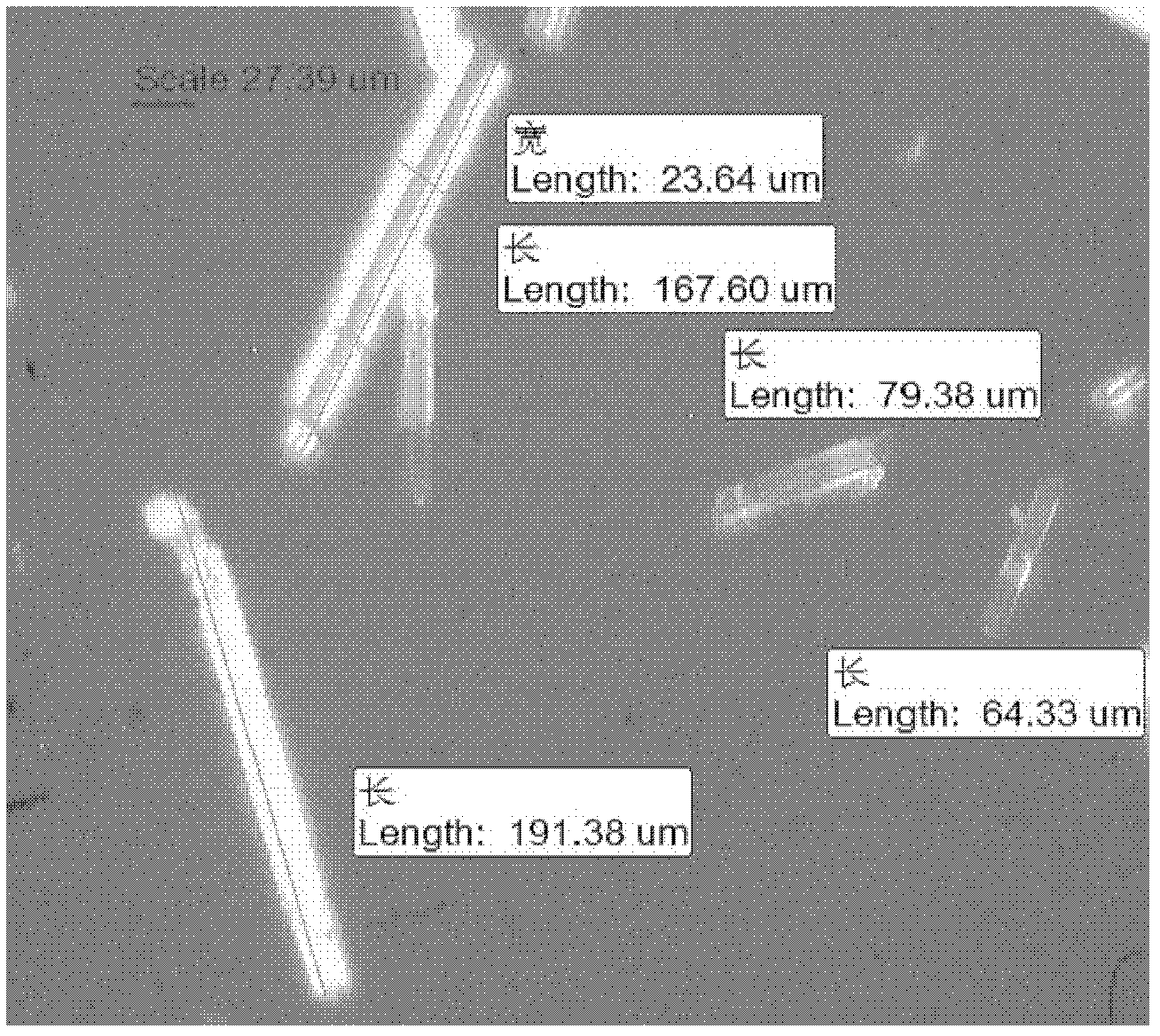

[0027] According to the above process, a phosphoric acid production enterprise, phosphoric acid tail gas 60000m 3 / h, based on orthophosphoric acid, the phosphorus content in the flue gas is 500mg / m 3 , sulfur dioxide concentration at 2500mg / m 3 about. With quicklime as the desulfurizing agent, the mass percent concentration of the desulfurizing absorbent in the slurry is 25%, the mass concentration of sodium dodecylbenzenesulfonate in the additive mixture liquid is 200mg / L in terms of active matter, and the mass concentration of adipic acid is 6g / L, the additive mixed solution is mixed with the overflow liquid in a ratio of 1:3, the mass percent concentration of the desulfurization absorbent in the slurry after mixing is 19%, and the mass concentration of sodium dodecylbenzenesulfonate is 50mg / L L, the mass concentration of adipic acid is 1.5g / L, the pH value of the slurry in the absorption tower is 5.3, and the concentration of sulfur dioxide at the outlet is 120mg / m 3 Ar...

Embodiment 2

[0029] According to the flow process of embodiment 1, a certain enterprise penta-sodium phosphoric acid production boiler, penta-sodium phosphoric acid tail gas 153000m 3 / h, based on orthophosphoric acid, the phosphorus content in the flue gas is 800mg / m 3 , the concentration of sulfur dioxide is 2300mg / m 3 about. Limestone is used as the desulfurizing agent, the mass percent concentration of the desulfurizing absorbent in the slurry is 25%, the concentration of sodium dodecylbenzenesulfonate in the additive mixture liquid is 240mg / L in terms of active matter, and the concentration of adipic acid is 9g / L, the additive mixed solution is mixed with the overflow liquid in a ratio of 1:5, the mass percent concentration of the desulfurization absorbent in the slurry after mixing is 20.7%, and the mass concentration of sodium dodecylbenzenesulfonate is 40mg / L, The mass concentration of adipic acid is 1.5g / L, the pH value of the slurry in the absorption tower is 4.5, and the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com