Method for refining bee venom

A refining method and technology of bee venom, applied to medical preparations containing active ingredients, pharmaceutical formulas, unknown raw materials, etc., can solve problems such as allergies, easy to cause pain, and affect the promotion and use of bee venom preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

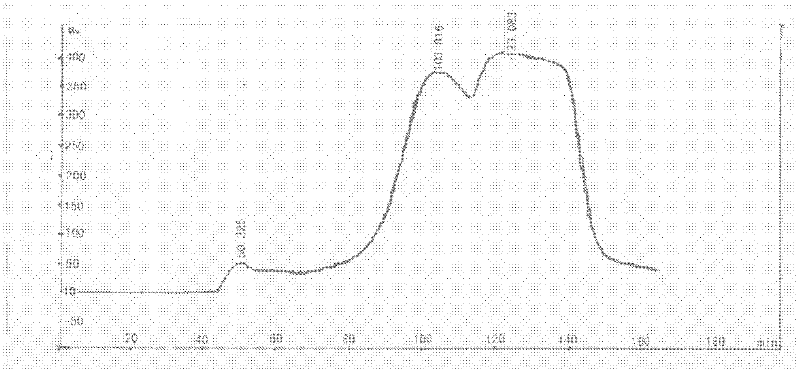

Image

Examples

Embodiment Construction

[0017] Non-limiting examples are described as follows:

[0018] (1) Preparation of bee venom crude product

[0019] 1. Dissolve

[0020] Take bee venom and add 8 times the weight of deionized water to dissolve, centrifuge at high speed (3000rpm) for 12 minutes, pour out the supernatant, add deionized water to the residue (same as the first water addition), and operate in the same way at high speed After centrifugation, filter and separate, combine the aqueous phase, and set aside.

[0021] 2. Precipitation:

[0022] Add 1 times the volume of acetone to the above water phase, let it stand at -10°C for 12 hours, pour off the supernatant, add acetone to the precipitate and crush the precipitate, filter, evaporate the acetone from the precipitate at low temperature , to get crude bee venom.

[0023] (2) Refining of crude products

[0024] 3. Dissolve the crude bee venom with 0.1mol / L acetic acid solution, put it on Sephadex G50 chromatography column [(2.0-10.0cm)×100cm], elut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com