Compound betamethasone suspension injection and preparation method thereof

A technology of betamethasone dipropionate and injection, which is applied in liquid delivery, pharmaceutical formula, emulsion delivery, etc., and can solve problems such as dynamic instability of betamethasone dipropionate suspended particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

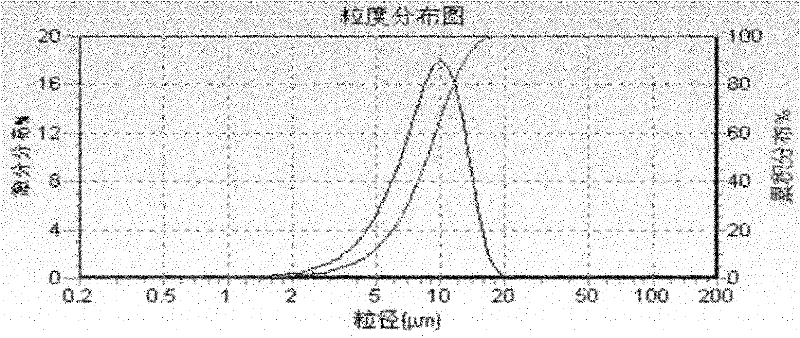

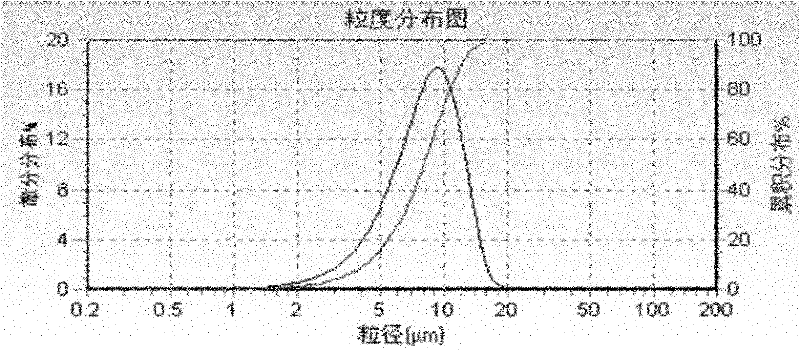

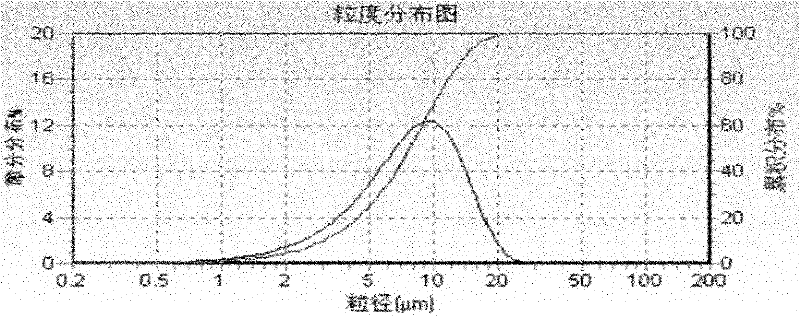

Image

Examples

Embodiment 1

[0109] (1) Formula

[0110] Betamethasone Dipropionate 64.6g Sodium Chloride 15g

[0111] Betamethasone Sodium Phosphate 26.6g Mannitol 100g

[0112] Methylparaben 5g Macrogol 4000 50g

[0113] Benzyl Alcohol 50g Sodium Edetate Calcium 4g

[0114] Tween-80 5g Disodium Hydrogen Phosphate 125g

[0115] Sodium Carboxymethyl Cellulose 100g Phosphoric Acid 10g

[0116] Add water for injection to make up to 10000ml

[0117] (2) Preparation method

[0118] 1) Prepare sterile betamethasone dipropionate suspension

[0119] ①Preparation of sodium carboxymethyl cellulose solution

[0120] Take the prescribed amount of sodium carboxymethyl cellulose, swell in a class 10,000 clean room with heated water for injection and stir, cool to room temperature, and pass through a 10um filter membrane to obtain solution (I).

[0121] ② Preparation of sterile matrix solution

[0122]Take the prescribed amount of benzyl alcohol, Tween-80, and methylparaben, stir and dissolve in a water bath a...

Embodiment 2

[0133] (1) Formula

[0134] Betamethasone Dipropionate 64.6g Carmellose Sodium 100g

[0135] Betamethasone Sodium Phosphate 26.6g Sodium Chloride 15g

[0136] Methylparaben 10g Mannitol 100g

[0137] Benzyl Alcohol 70g Macrogol 4000 50g

[0138] Tween-80 5g Sodium Edetate Calcium 4g

[0139] Disodium hydrogen phosphate 125g Phosphoric acid 10g

[0140] Add water for injection to make up to 10000ml

[0141] (2) Preparation method

[0142] 1) Prepare sterile betamethasone dipropionate suspension

[0143] ①Preparation of sodium carboxymethyl cellulose solution

[0144] Take the prescribed amount of sodium carboxymethyl cellulose, swell in a class 10,000 clean room with heated water for injection and stir, cool to room temperature, and pass through a 10um filter membrane to obtain solution (I).

[0145] ② Preparation of sterile matrix solution

[0146] Take the prescribed amount of benzyl alcohol, Tween-80, and methylparaben, stir and dissolve in a water bath at 40°C in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com