Preparation method of vegetable fat powder

A vegetable fat and vegetable oil technology, applied in dairy products, cream preparations, applications, etc., can solve the problems of not taking into account taste and aroma factors, and achieve the effects of enhancing storage stability, reasonable price and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

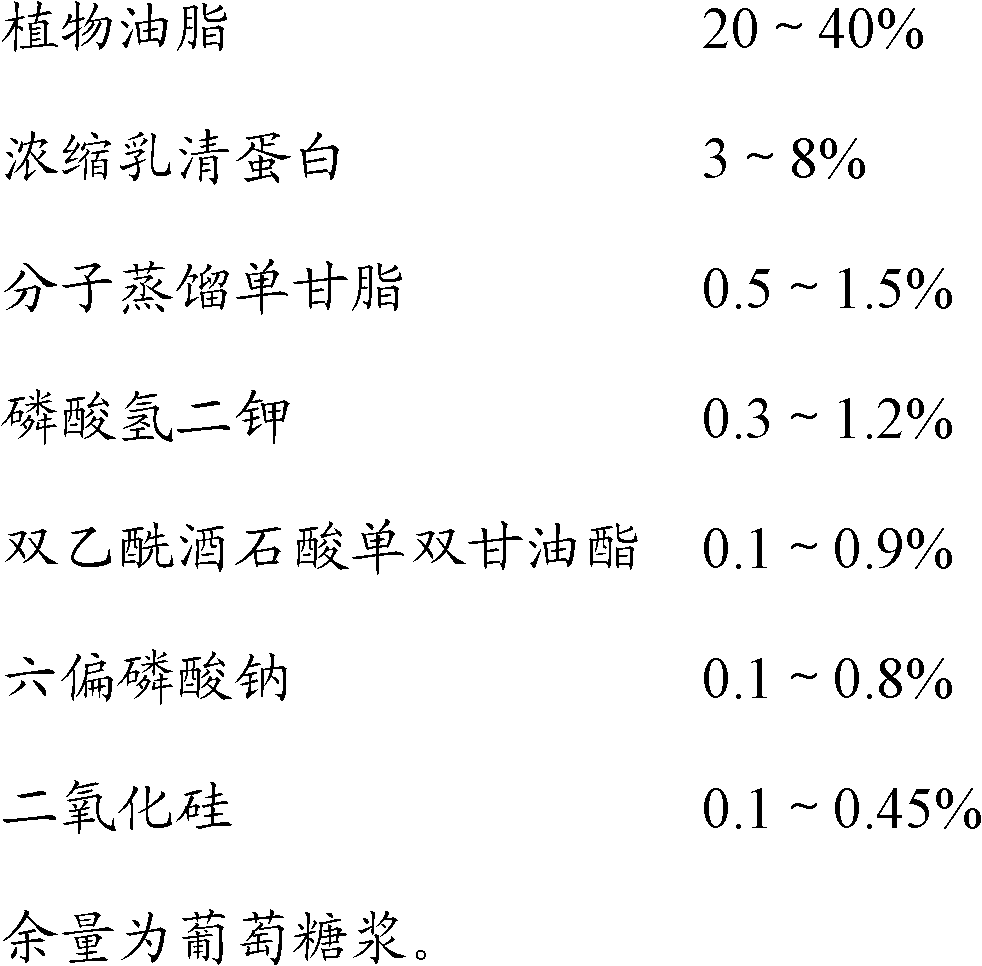

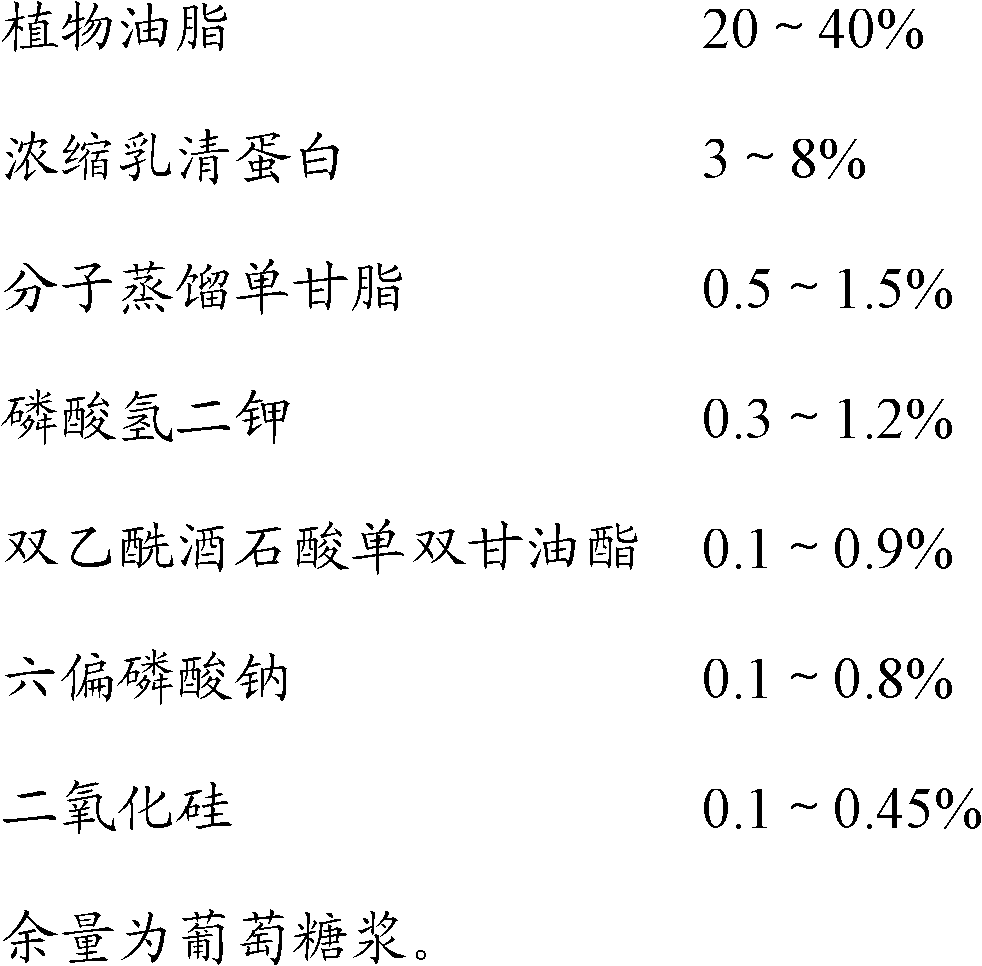

Method used

Image

Examples

Embodiment 1

[0043] 1. Emulsification and homogeneous embedding process: mix 35g of coconut oil, 0.8g of molecularly distilled monoglyceride, and 0.7g of diacetyl tartaric acid monoglyceride in an emulsification tank; G, dipotassium hydrogen phosphate 1.0g, sodium hexametaphosphate 0.7g and 22.4g water are mixed in the high-speed mixing tank; Then the material in the above-mentioned two tanks is added to 77.62g glucose syrup (DE value is 30%; and Appearance is clear and free of impurities, no smell of glucose syrup) mixed in a shear tank, homogenized (homogeneous pressure 30MPa, slurry temperature 60 ℃ during homogenization) 30min, to obtain the emulsion of vegetable fat powder;

[0044] 2. Spray-drying process: Spray-dry the emulsion obtained in 1. The feed temperature of spray-drying is 65°C, the inlet air temperature is 180°C, and the exhaust air temperature is 95°C to obtain the primary product of vegetable fat powder, and then add 0.4 g of silicon dioxide to obtain the finished vegeta...

Embodiment 2

[0047] 1. Emulsification and homogeneous embedding process: Mix 35g of palm kernel oil and 0.7 span, 0.1g of propylene glycol ester, and 0.45g of soybean lecithin in an emulsification tank; mix 5g of concentrated whey protein (protein content 70wt%), , dipotassium hydrogen phosphate 0.4g, sodium tripolyphosphate 0.5g and 22.1g water are mixed in the high-speed mixing tank; Clear and impurity-free, odorless glucose syrup) shearing and mixing in a shearing tank, homogenization (homogeneous pressure 40MPa, slurry temperature 50°C during homogenization) for 40min, to obtain the emulsion of vegetable fat powder;

[0048] 2. Spray-drying process: Spray-dry the emulsion obtained in 1. The feed temperature of spray-drying is 55°C, the inlet air temperature is 160°C, and the exhaust air temperature is 72°C to obtain the primary product of vegetable fat powder, and then add 0.4 g of sodium aluminosilicate to obtain the finished vegetable fat powder finished product of whey protein micro...

Embodiment 3

[0051] 1. Emulsification and homogeneous embedding process: Mix peanut oil 30g, palm kernel oil 10g, soybean lecithin 0.2g, distilled glyceride 0.12g, sucrose fatty acid ester 0.6g in an emulsification tank; concentrate whey protein (protein content 34wt %) 11g, sodium hexametaphosphate 0.7g, potassium dihydrogen phosphate 0.91g and 25.8g water are mixed in the high-speed mixing tank; ; and the appearance is clear and free of impurities, and the glucose syrup without peculiar smell) is sheared and mixed in a shear tank, homogenized (homogeneous pressure 20MPa, homogeneous temperature 50 ℃) for 40min, and the emulsion of vegetable fat powder is obtained;

[0052] 2. Spray-drying process: Spray-dry the emulsion obtained in 1. The feed temperature of spray-drying is 55°C, the inlet air temperature is 180°C, and the exhaust air temperature is 85°C to obtain the primary vegetable fat powder, and then add 0.4 The anticaking agent of g, obtains the vegetable fat powder finished produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com