Standardized component for assembling pet house/furniture/mobile room

A pet house and activity room technology, applied in the field of standardized components, can solve problems such as unfavorable splicing, unsightly appearance, and inability to connect directly, achieving the effects of convenient assembly and disassembly, convenient transportation or carrying, and saving installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

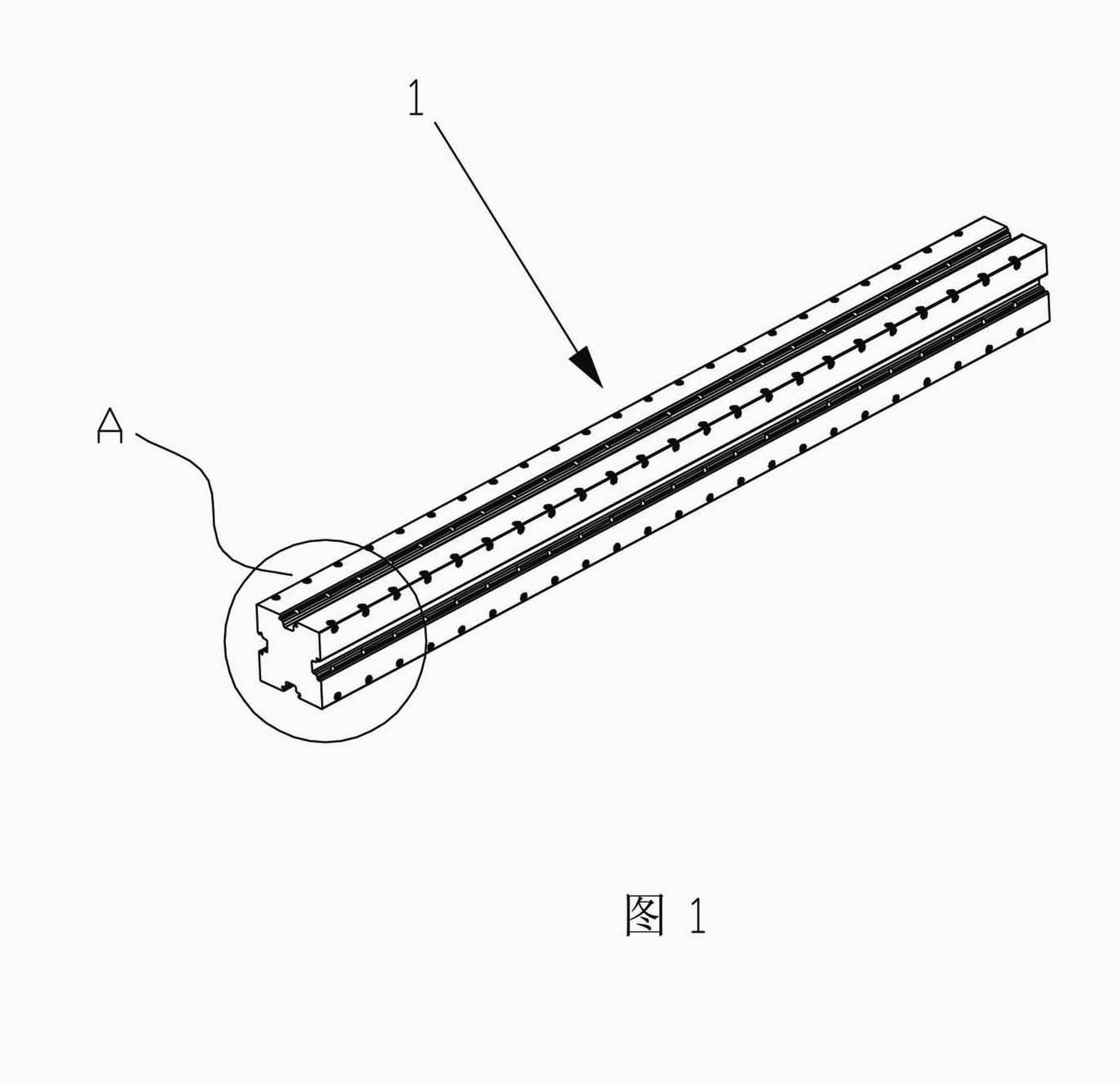

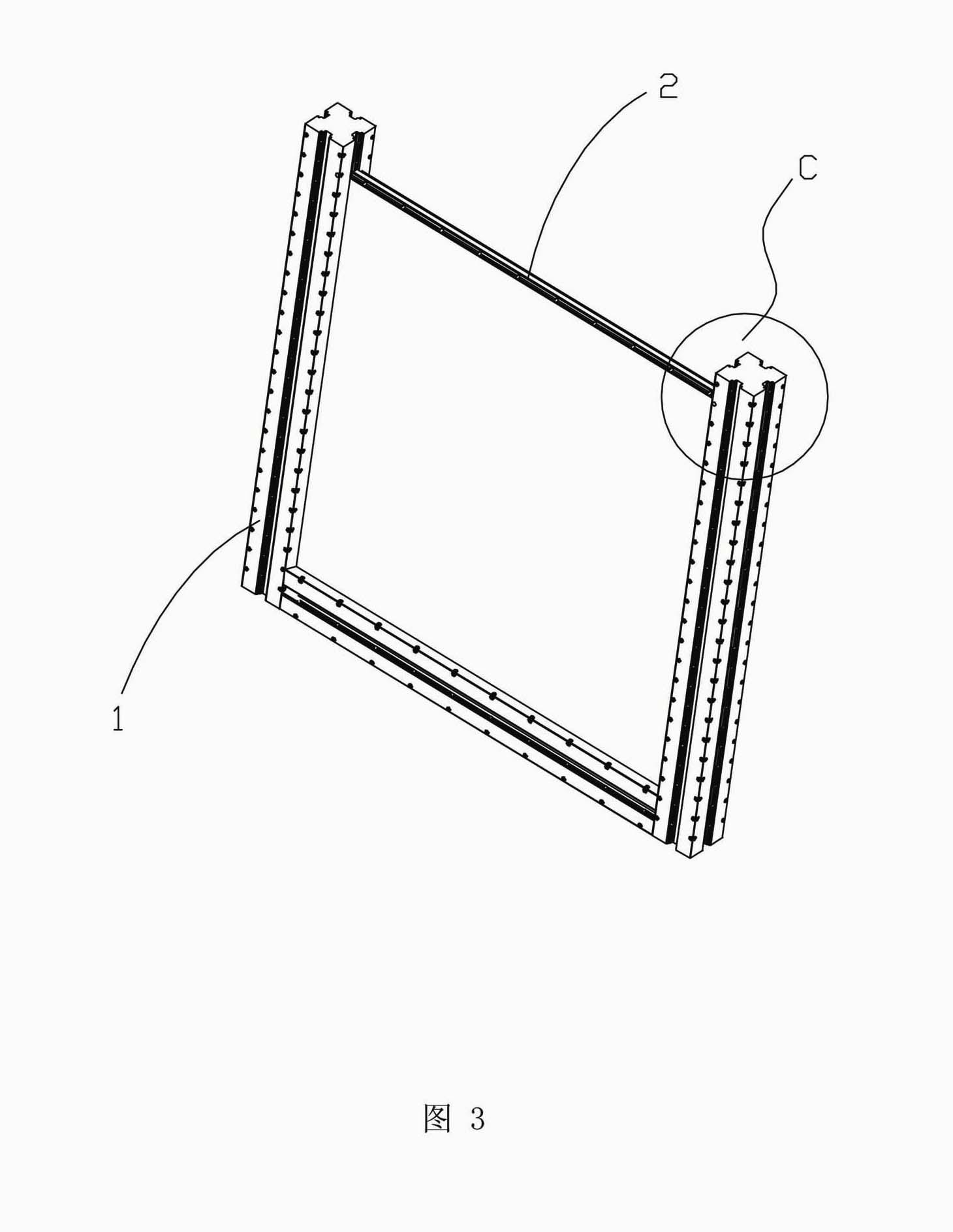

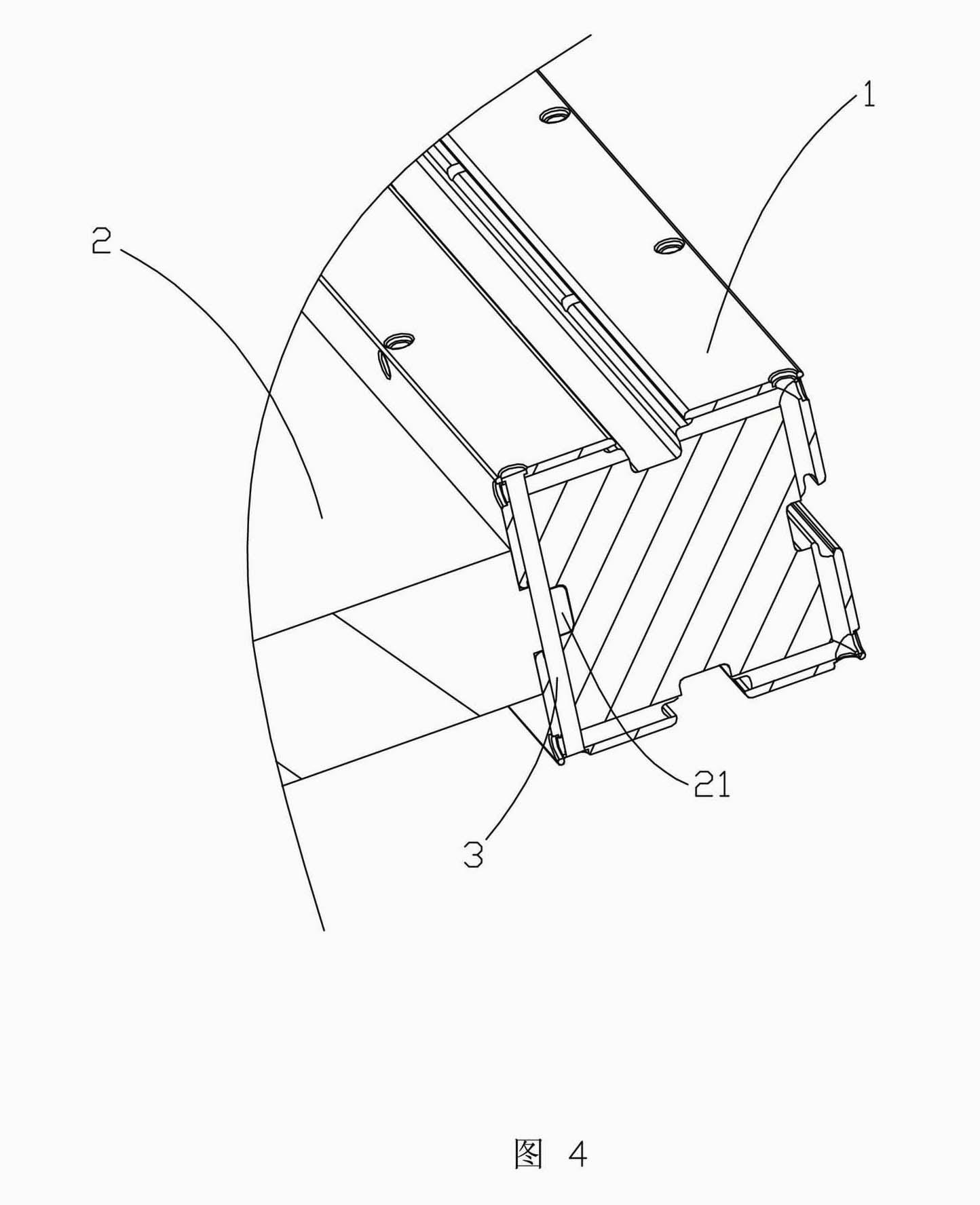

[0038] Standardized components for assembling pet houses / furniture / facility, refer to figure 1 and figure 2 , including a panel 2 and a connecting strip 1 connecting two panels 2, the thickness of the panel 2 is less than the cross-sectional side length of the connecting strip 1, the panel 2 includes four sides, and each side is provided with a raised strip 21 (such as Image 6 shown); the connection bar 1 is extruded, which is convenient to produce, and can be produced in a large scale, and the cost is low. refer to Figure 5 , any cross-section of the connecting strip 1 is equal, and the four side walls of the connecting strip 1 are respectively provided with slots 11 matched with the convex strips 21; refer to Figure 5 and Image 6 , a number of pin holes 22 are equidistantly distributed on the convex strip 21 of the panel 2, the distance between the pin hole 22 near the end of the convex strip 21 and its nearest end is half of the distance between the two adjacent pin...

Embodiment 2

[0040] Present embodiment also comprises panel 4 and the connection bar 5 that connects two panels 4, with reference to Figure 14 , the panel 4 is constructed by two surface boards and a bracket integrally connected between the two surface boards and the two surface boards, and its interior is hollow; refer to Figure 9 , Figure 13 and Figure 14 , the thickness of the panel 4 is equal to the cross-sectional side length of the connecting strip 5, the side of the panel 4 is provided with a slot 41, each panel 4 has two sides and four sides, and the four sides are respectively composed of a plurality of The same minimum unit is composed of each minimum unit consisting of a slot 41 and the side walls surrounding the slot, the side walls of two adjacent slots 41 are connected as one, and the two slots 41 on both sides of the corner of the panel 4 are connected to each other. Connected and overlapping; the connection bar 5 is the same as the connection bar 1 of the first embodi...

Embodiment 3

[0043] This embodiment is roughly the same as embodiment two, refer to Figure 16 and Figure 17 , the main difference is that the thickness of the panel 8 is less than the length of the cross-section of the connecting strip 9, and between the panel 8 and the insert block 10, between the connecting strip 9 and the insert block 10 are respectively inserted into corresponding pin holes by pins of different sizes fixed connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com