Belt-like annular flow drying machine

A dryer and circulating fan technology, applied in the direction of dryers, drying, drying solid materials, etc., can solve the problems of high temperature of materials, achieve the effect of small gap, reduce heat loss, and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

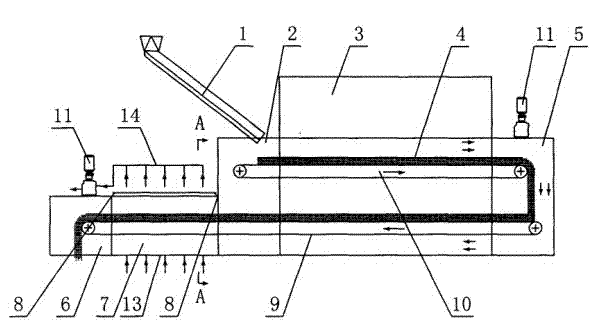

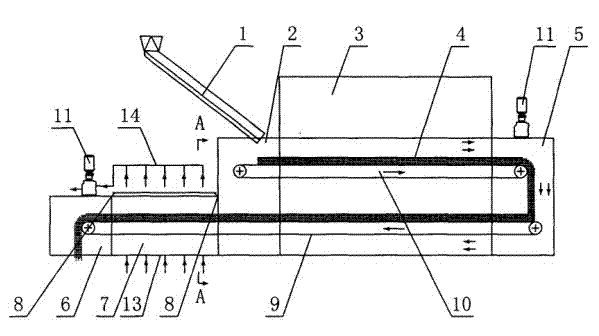

[0022] Such as figure 1 and figure 2 Shown, a kind of belt type circulating dryer, it comprises feed section 2, middle section 3, tail section 5, discharge section 6, cooling section 7, lower conveyor belt 9, upper conveyor belt 10, circulation blower 11 and Cooling fan 12. Among them: the feeding section 2, the middle section 3 and the tail section 5 are sequentially connected to form an integral casing, the upper conveyor belt 10 and the lower conveyor belt 9 are located in the integral casing, the circulating fan 11 is located on the tail section 5, and the side of the cooling section 7 Connect the discharge side of the overall casing, the other side of the cooling section 7 is connected to the discharge section 6, the lower conveyor belt 9 is connected to the discharge section 6 through the cooling section 7, and there is a gap 13 communicating with the atmosphere below the cooling section 7 An air collecting hood 14 is arranged above the cooling section 7, and the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com