Refrigerating box with high-efficiency energy-saving evaporator

A high-efficiency energy-saving, evaporator technology, applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of uneven surface temperature of evaporator, large flow resistance of refrigerant, low surface temperature of evaporator, etc., to achieve Strong cost advantage, fast cooling speed and high cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

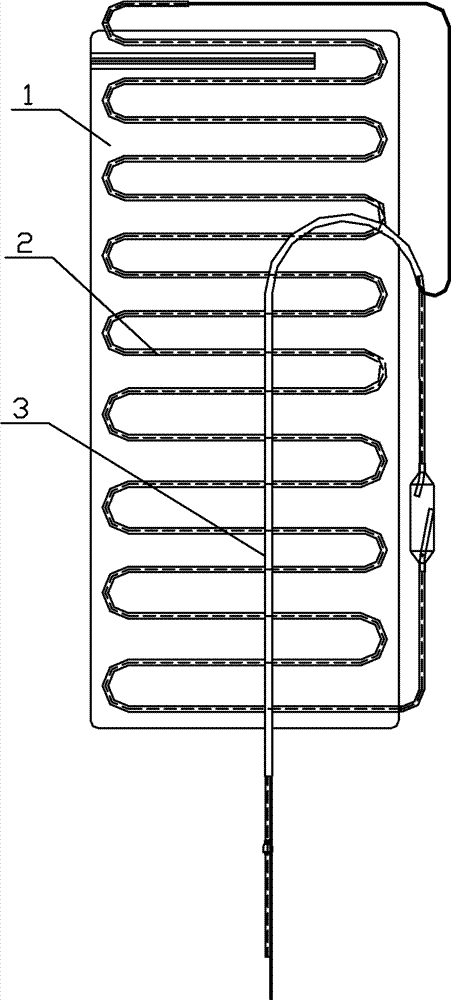

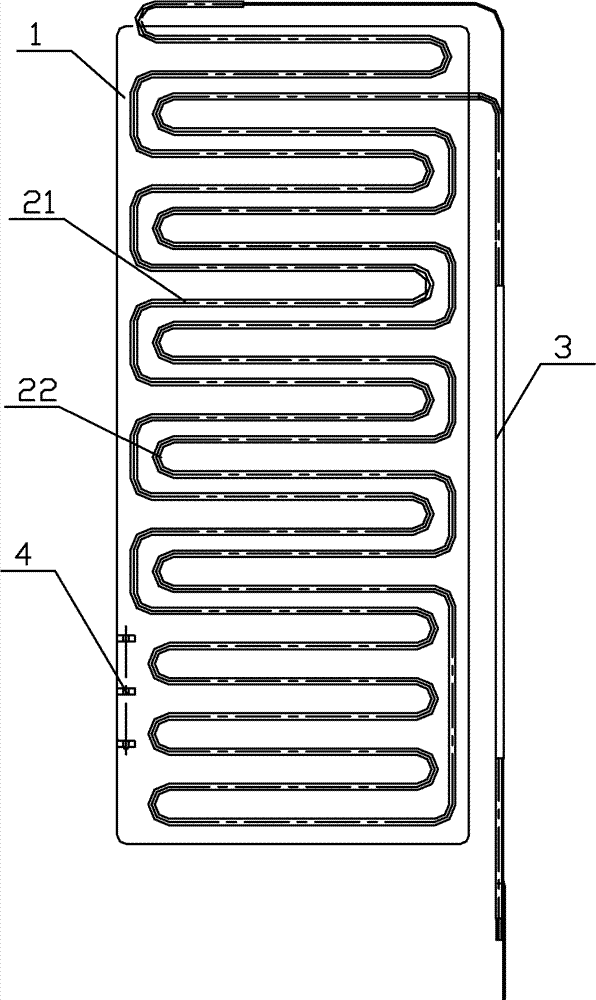

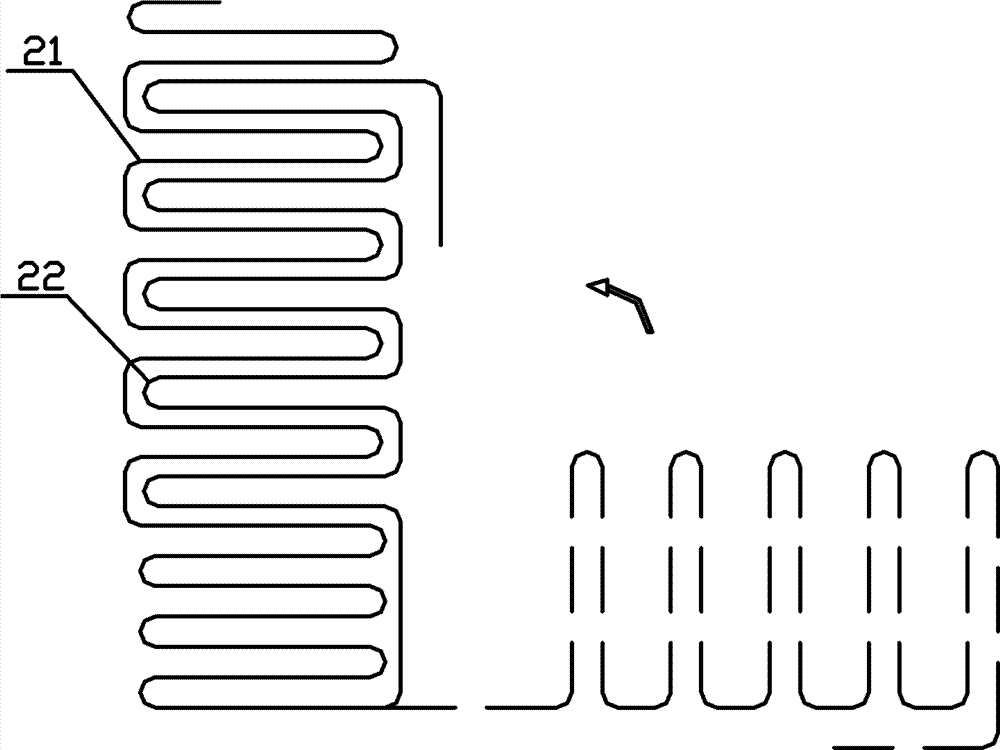

[0019] See figure 2 , is the evaporator structure used in the refrigerator of the present invention, and the trend of the evaporator tube is roughly S-shaped, but after the downward evaporator tube is distributed along the S-shaped direction of the evaporator plate from top to bottom, the up-link evaporator tube runs from the evaporator plate to The bottom of the evaporator pipe is arranged upwards, and follows the coiled shape of the descending evaporator pipe, and leaves from the upper end of the evaporator plate. The outlet pipe section of the descending evaporator pipe is the return pipe, and the return pipe is in contact with the capillary tube for heat exchange. The pipe is integrally bent and formed, and there is no welding joint in the middle. The return pipe and the capillary constitute the return pipe assembly. Moreover, the return pipe assembly of the present invention cancels the liquid receiver, and the refrigerant liquid storage function of the refrigeration syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com