Solid particle suction preventive type fluid dynamic pressure mechanical sealing ring

A mechanical seal and fluid dynamic pressure technology, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems that the seal ring does not reflect the removal of impurities, cannot effectively prevent the inhalation of solid particles, and reduce friction and wear. Achieve the effects of improving friction and lubrication conditions, low processing costs, and reducing abrasive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The anti-solid particle inhalation type hydrodynamic mechanical seal ring of the present invention is a dynamic ring of mechanical seal, and the shape of the end surface can be processed by electrochemical corrosion, electric spark, laser processing and other processes.

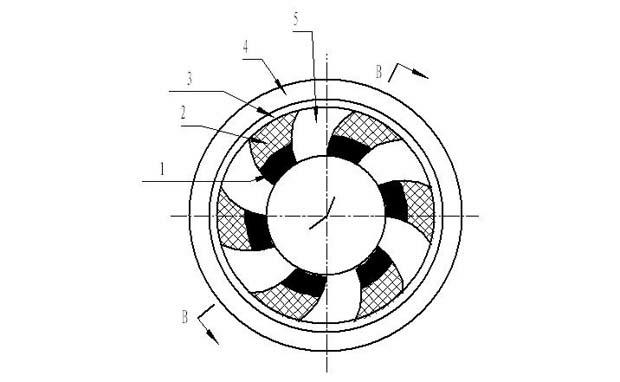

[0014] figure 1 It is a schematic diagram of the end surface groove of the sealing ring of the present invention used for gas sealing. The outer diameter end of the sealing ring is the pumping end. From the outside to the inside, the grain-repelling groove, the dynamic pressure groove, the grain-storing groove, the grain-repelling groove and the dynamic pressure groove are distributed sequentially. The groove shape of the groove is continuous and consistent, which is a spiral shape. The grain storage tank is a circular groove, which is opened at the end of the dynamic pressure groove. The depth of the grain resistance groove is 2.5um, and the depth of the dynamic pressure groove is 5um to 10um. The dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com