Conical air floating shaft system

A technology for air-floating shafts and air-floating spindles, applied to bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of easy dry friction and low positioning accuracy of air-floating shafting, achieve high centering accuracy and improve rigidity , Guarantee the effect of rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

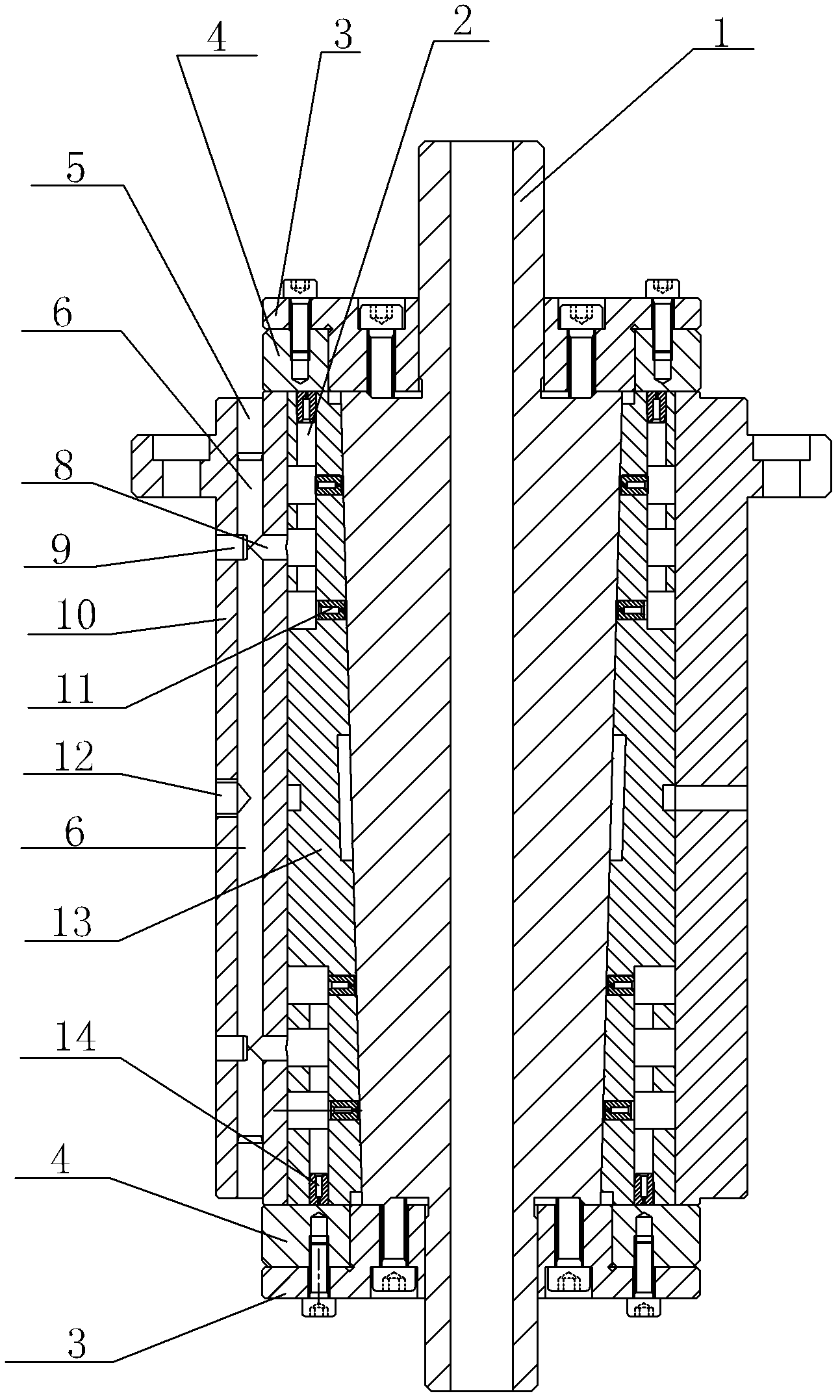

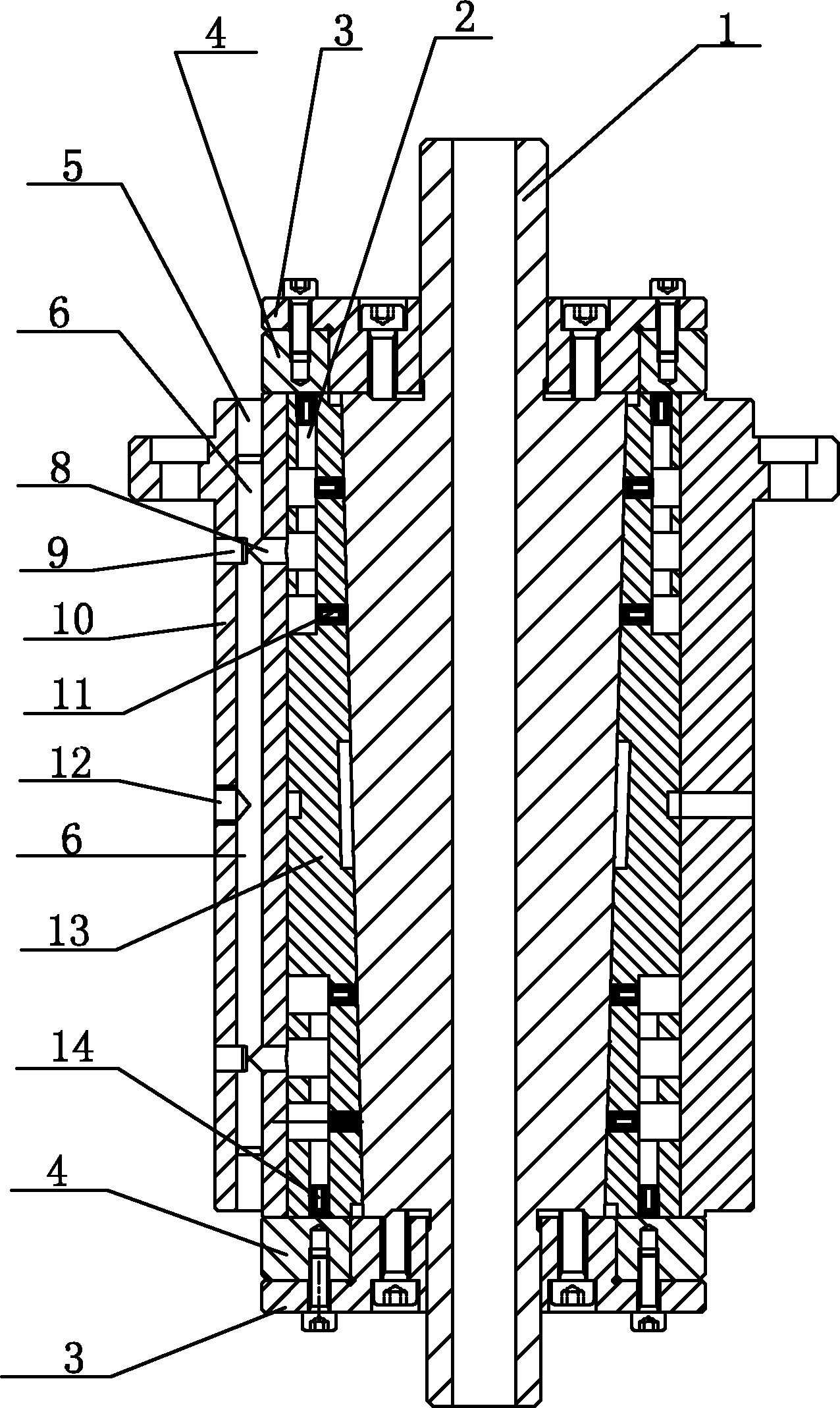

[0018] Such as figure 1 As shown, the conical air bearing shaft system includes the air bearing main shaft 1, the air bearing inner shaft sleeve 13 cooperating with the air bearing main shaft and arranged outside the air bearing main shaft, and the air bearing inner shaft sleeve cooperating with the air bearing inner shaft sleeve 13 The outer air-floating outer shaft sleeve 10 and the positioning plate 3 arranged at both ends of the air-floating main shaft 1, the positioning plate 3 is fixedly connected with the air-floating main shaft 1, and the two ends of the air-floating outer shaft sleeve 13 are provided with a thrust plate 4, the thrust plate 4 Plate 4 and positioning plate 3 are fixedly connected,

[0019] There is an air cavity 6 on the air flotation outer shaft sleeve. The air cavity 6 divides the air flotation outer shaft sleeve into an outer wall and an inner wall. The nozzle 12 is provided with an air outlet 8 communicating with the air chamber 6 on the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com