Driving/running type galling treatment machine

A kind of brushing machine and walking type technology, which is applied in the field of driving and walking type brushing machine, can solve the problems of not obviously improving the working conditions of the operator, increasing the cost and energy consumption, and finding no alternative technology, etc., and achieves high construction efficiency. , walking and steering flexibility, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

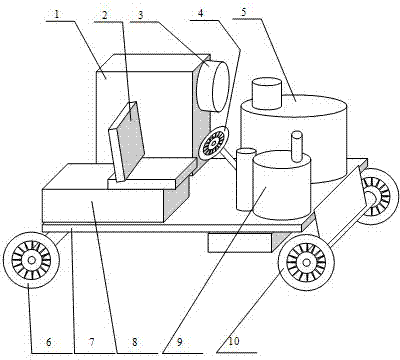

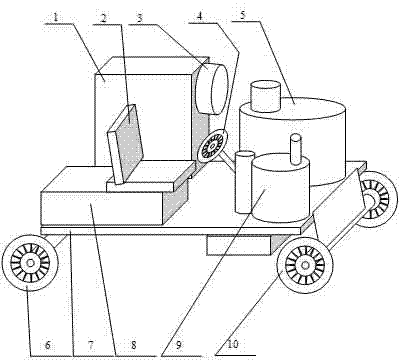

[0020] Front wheel set 10 and rear wheel set 6 are installed below frame 7, diesel engine 5, vacuum cleaner 1, generator 8 and seat 2 are installed above frame 7, control device, driving and steering device are installed in seat 2 front, frame Shot blasting machine 9 is also installed on 7.

[0021] A blower fan 3 is installed on the vacuum cleaner 1. The driving and steering device includes a steering wheel 4 .

[0022] The steel ball injection device at the bottom of the shot blasting machine 9 is installed below the frame 7, and the dust suction port of the vacuum cleaner 1 is installed at the corresponding port.

[0023] The generator 8 is installed on the rear side of the frame 7, the seat 2 is installed above the generator 8, the shot blasting machine 9 is installed on the same side of the front of the generator 8, the diesel engine 5 is installed on the other side of the frame 7, and the rear is installed Vacuum cleaner1.

[0024] As an example, the frame 7 is 1160mm...

Embodiment 2

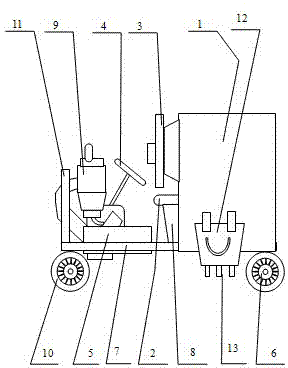

[0026] As another embodiment, a gantry 11 is fixed at the front end of the frame 7, an ash unloading bucket 12 is installed next to the vacuum cleaner 1, and a walking wheel 13 is installed at the bottom of the ash unloading hopper 12. The shot blasting machine 9 is installed on the gantry 11 and can move up and down. .

[0027] Wherein, diesel engine 5 power is 25 horsepowers, as the power source of driving shot blasting machine 9, blower fan 3 and generator 8 work; It is convenient for the ash unloading hopper 12 to move to the runner.

[0028] When working, first turn on the diesel engine 5, the fan 3 is clutched and combined, start the 48V power switch, drive the front wheel set 10 or the rear wheel set 6 to move forward, and then start the control device of the shot blasting machine 9 to start sand supply. , unloading the ash hopper 12 on the vacuum cleaner 1, and the ash unloading hopper 12 moves through the walking wheels 13 at the bottom.

[0029]

Embodiment 3

[0031] The rear wheel drive mode is adopted, that is, the rear wheel pair 6 is a driving wheel, and the rear wheel pair 6 is connected with a rear axle differential device. The rear axle differential is driven by a 48V DC motor and is equipped with a stepless speed regulator.

[0032] This embodiment can meet the requirements of accurate and convenient control of walking speed during mechanical construction, and can achieve the effect of convenient and safe work.

[0033] The invention adopts the driving type walking mode, the efficiency is twice as high as that of the shot blasting machine 9 of the same model, and the energy saving is 60%. Energy-saving effect, in terms of performance, it has realized intelligence, miniaturization, high efficiency, energy saving, integration and dust-free.

[0034] The invention has a driving steering wheel control, the operator completes the work as if driving a car, electric start, fully automatic recovery of steel shot, clutch type contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com