Ladle refining deep desulphurization method for low-carbon aluminum killed steel

A technology for low-carbon aluminum killed steel and ladle refining, which is applied in the field of ladle refining and desulfurization and deep desulfurization in ladle refining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 The present embodiment adopts the technology of the present invention, and carries out experiment on X70 pipeline steel, and ladle is 180 tons, and it comprises following operation:

[0021] 1) Converter blowing end point [S]=0.0098%, [O]=687ppm. The slag is strictly prevented during the tapping of the converter. During the tapping process, 308kg of aluminum particles and 434kg of lime are added, and all the slag is added within 2 minutes before the end of tapping. Add 20kg of aluminum particles on the slag surface after tapping.

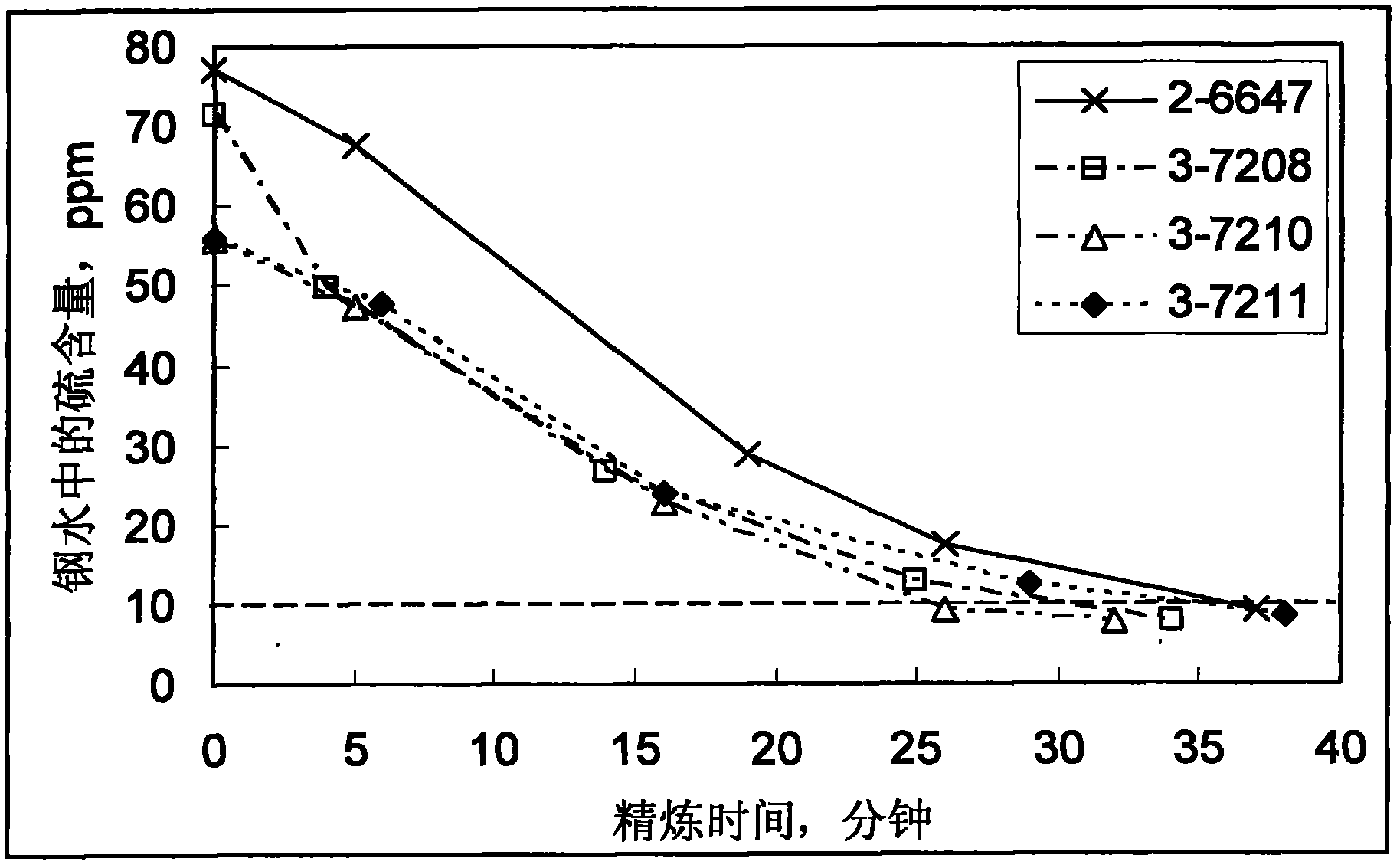

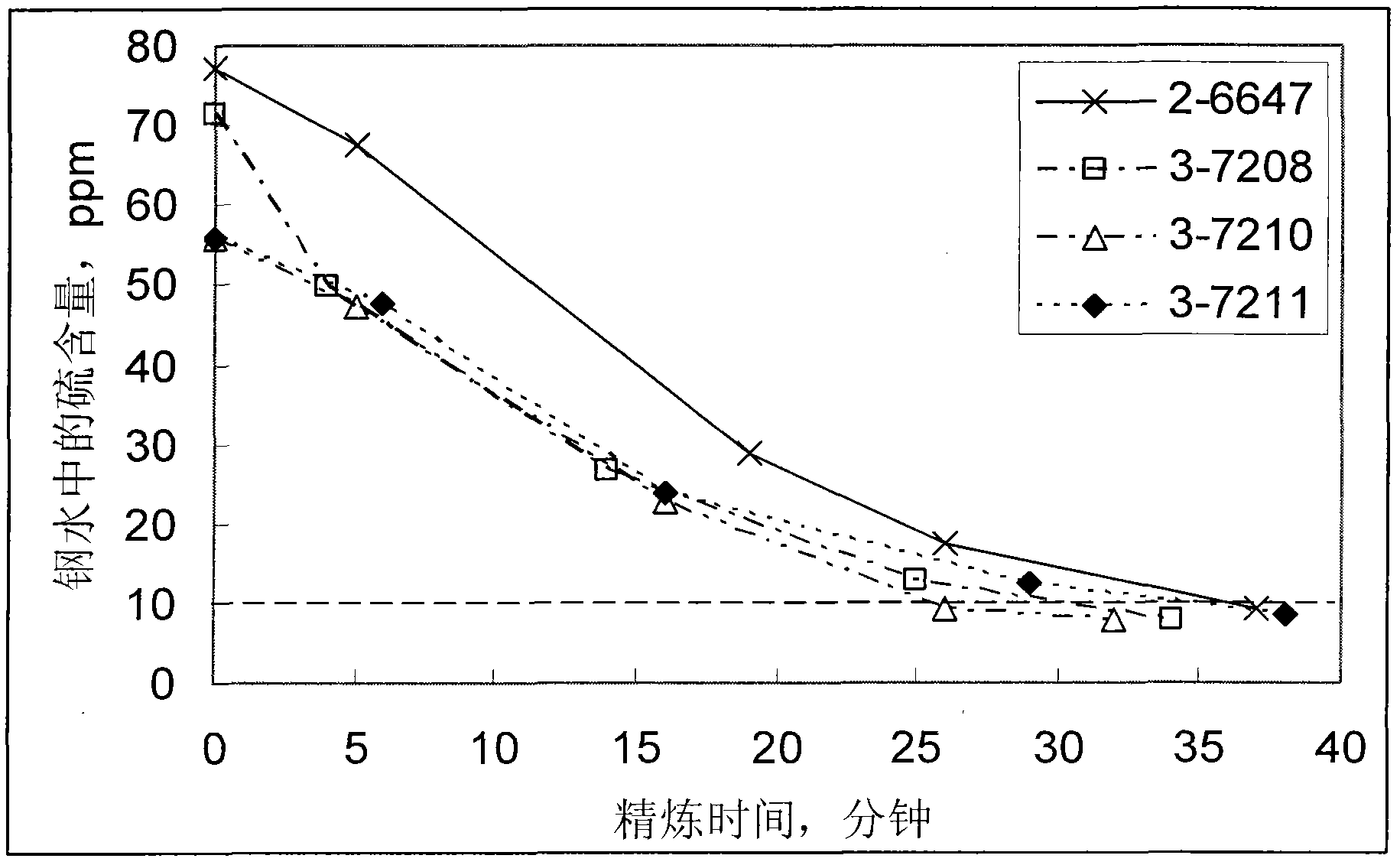

[0022] 2) When the ladle arrives at the station, take samples of slag and molten steel for analysis. When the ladle arrives at the station, [S]=0.0077% in molten steel, [Als]=0.0789% (see figure 1 2-6647 heat times), add lime 438kg, and energize the slag, and the molten steel temperature is 1568 ℃ when it arrives at the station for 5 minutes. During the refining process, the total flow rate of the ladle bottom blowing gas is c...

Embodiment 2

[0023] Embodiment 2 The present embodiment adopts the technology provided by the present invention to carry out experiments on X70 pipeline steel, and the ladle is 180 tons, which includes the following operations:

[0024] 1) Converter blowing end point [S] = 0.01%, [O] = 526ppm. The slag is strictly prevented during the tapping of the converter. During the tapping process, 330kg of aluminum particles and 430kg of lime are added, and all the slag is added within 2 minutes before the end of the tapping. Add 17kg of aluminum particles on the slag surface after tapping.

[0025] 2) When the ladle arrives at the station, take samples of slag and molten steel for analysis. When the ladle arrives at the station, [S]=0.00716% in molten steel, [Als]=0.0558% (see figure 1 3-7208 furnace times), add 350kg of lime, and electrify the slag, and the temperature of the molten steel at the station is 1541°C. During the refining process, the total flow rate of the ladle bottom blowing gas ...

Embodiment 3

[0026] Embodiment 3 The present embodiment adopts the technology provided by the present invention to carry out experiments on X70 pipeline steel, and the ladle is 180 tons, which includes the following operations:

[0027] 1) Converter blowing end point [S]=0.0073%, [O]=437ppm, temperature T=1619°C. The slag is strictly prevented during the tapping of the converter. During the tapping process, 273kg of aluminum particles and 430kg of lime are added, and all the slag is added within 2 minutes before the end of the tapping.

[0028] 2) When the ladle arrives at the station, take samples of slag and molten steel for analysis. When the ladle arrives at the station, [S]=0.0056% in molten steel, [Als]=0.0518% (see figure 13-7210 heats), add 250kg of lime, and electrify the slag, and the molten steel temperature is 1554°C when it arrives at the station for 5 minutes. During the refining process, the total flow rate of the ladle bottom blowing gas is controlled at 1.5-7NL / (min·t), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com