Composite cementitious material of desulfurated waste residue and mortar prepared from same

A technology of desulfurization waste residue and composite gel, which is applied in cement production and other directions, can solve the problems of high energy consumption, restrict the efficient utilization of desulfurization waste residue, etc., and achieve the effects of low production energy consumption, material cost reduction, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

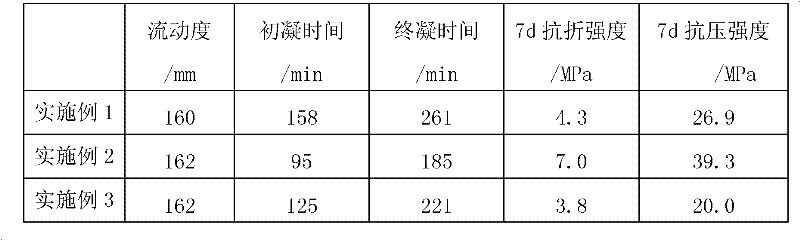

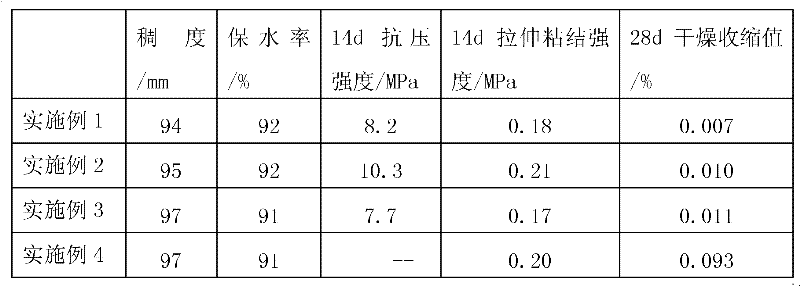

Embodiment 1

[0017] Be 70% industrial chemical gypsum (main component is CaSO 4 ) and 30% desulfurization waste slag are evenly mixed, and ground until the sieve residue is less than 20% (0.08mm square hole sieve), to prepare the desulfurization waste slag composite gelling material.

[0018] 25kg of the desulfurization waste slag composite cementitious material prepared above, 1kg of mortar thickening powder, and 74kg of sand were added to 15.8kg of water and stirred evenly to obtain a desulfurization waste slag mortar material.

Embodiment 2

[0020] Composition (percentage by weight) is: 70% industrial chemical gypsum (main component is CaSO 4 ), 28% of desulfurization waste slag (a mixture of dry desulfurization ash and semi-dry desulfurization ash in a weight ratio of 1:1), 1% of chemical additives (potassium sulfate, aluminum sulfate and alum in a weight ratio of 1:1:1 Ratio mixture) and mix evenly, and grind until the sieve residue is less than 20% (0.08mm square hole sieve), to prepare high-strength desulfurization waste slag composite gelling material.

[0021] 25kg of the desulfurization waste slag composite cementitious material prepared above, 1kg of mortar thickening powder, and 74kg of sand were added with 15.8% water and stirred evenly to obtain a desulfurization waste slag mortar material.

[0022] The chemical additive can also use any ratio of alum or potassium sulfate and aluminum sulfate mixture, or use alum, potassium sulfate or aluminum sulfate alone.

Embodiment 3

[0024] Composition (percentage by weight) is: 60% industrial chemical gypsum (main component is CaSO 4 ), 20% of desulfurization waste slag (the compound of wet desulfurization gypsum and dry desulfurization ash in 1:1 weight ratio), 20% of inorganic mineral additives (mixture of fly ash, cement, mineral powder and steel slag in any ratio) Mix evenly, grind until the sieve residue is less than 20% (0.08mm square hole sieve), and prepare the desulfurization waste slag composite gelling material.

[0025] 25kg of the desulfurization waste slag composite cementitious material prepared above, 1kg of mortar thickening powder, and 74kg of sand were added to 16.4kg of water and stirred evenly to obtain a desulfurization waste slag mortar material.

[0026] Inorganic mineral additives can also use fly ash, cement, mineral powder or steel slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com