Alkali silicate glass frit, zirconium frit opaque glaze, zirconium raw material opaque glaze and preparation methods of the zirconium frit opaque glaze and the zirconium raw material opaque glaze

A technology of glass frit and alkali silicate, which is applied in the fields of alkali silicate glass frit, opaque glaze and preparation thereof, zirconium opaque glaze and preparation thereof, and can solve the problem of reducing the production cost of opaque glaze and reducing raw materials The types of use and production costs are high, so as to reduce the burden of post-processing, reduce the types of raw materials, and improve the environment and social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

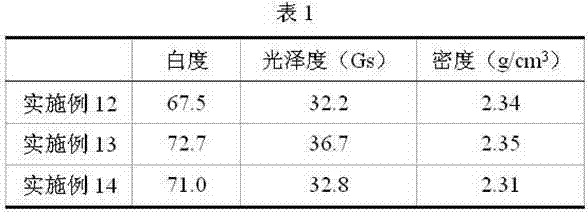

Examples

Embodiment 1

[0041] The frit is made from waste silica gel and soda ash, wherein the waste silica gel contains 5-12wt% zirconia and the rest is silica. In the raw materials, the amount of waste silica gel and soda ash meets the requirement of introducing SiO 2 and Na 2 The molar ratio of O is 75:25, which is 3:1. The frit is prepared as follows:

[0042] 1. Take waste silica gel and soda ash in proportion, mix them evenly, and heat them to 1280°C in an electric furnace or kiln to melt them;

[0043] 2. Quench the molten glass with water, filter it dry, and dry it at 120°C to obtain a frit. The resulting frit can be directly used as a raw material for producing water glass (commonly known as sodium silicate), and can also be used as a raw material for opacified glaze.

Embodiment 2

[0045] The frit is made from waste silica gel and soda ash, wherein the waste silica gel contains 5-12wt% zirconia and the rest is silica. In the raw materials, the amount of waste silica gel and soda ash meets the requirement of introducing SiO 2 and Na 2 The molar ratio of O is 67:33, except that waste silica gel and soda ash are heated to 1250° C. for melting, other steps for preparing frit are as in Example 1.

Embodiment 3

[0047] The opaque glaze is made from waste silica gel, soda ash, clay and albite, wherein the waste silica gel contains 5-12wt% zirconia and the rest is silica. In the raw materials, the amount of waste silica gel and soda ash meets the requirement of introducing SiO 2 and Na2 The molar ratio of O is 75:25, that is, 3:1, and the amount of clay is 1% of the total amount of frit, and the amount of albite is 5% of the total amount of waste silica gel and soda ash. Waste silica gel and soda ash are added in the form of frit, and the method for preparing frit glaze is as follows:

[0048] 1. Take waste silica gel and soda ash in proportion, mix them evenly, and heat them to 1280°C in an electric furnace or kiln to melt them;

[0049] 2. Quench the molten glass with water, filter it dry, and dry it at 120°C to obtain a frit;

[0050] 3. Mix the frit with clay and albite for ball milling (material: water: ball mass ratio is 1:0.7:1.5);

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com