Recirculating aquaculture water treatment system and method

A technology of recirculation breeding and treatment system, applied in the field of water treatment system, can solve the problems of high SS in the effluent, difficult to remove spores, parasites and other substances, reduce operating costs, improve effluent quality and process stability, and prevent clogging of membranes tube effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

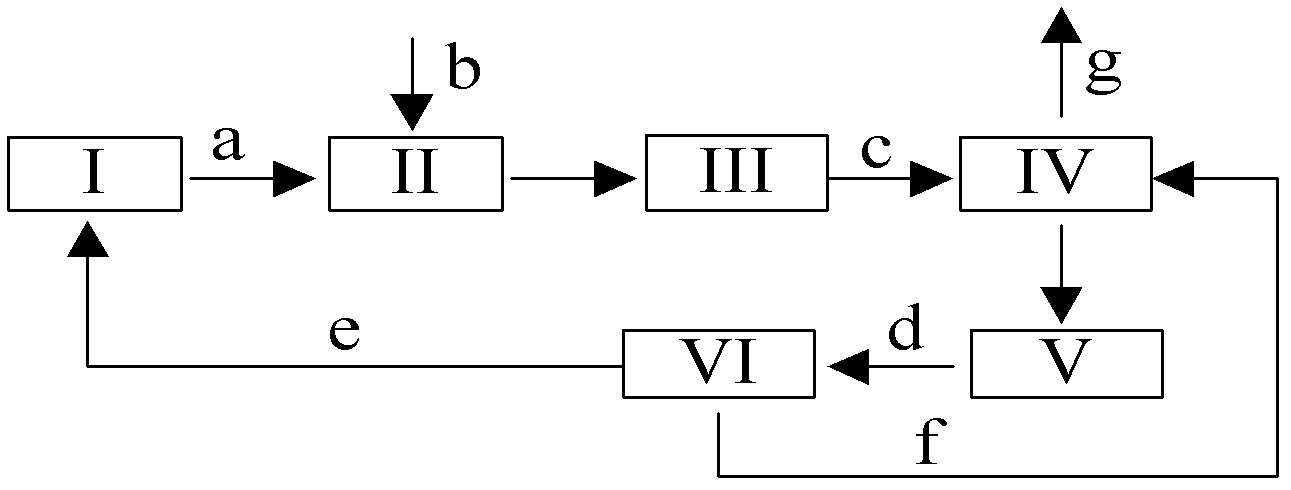

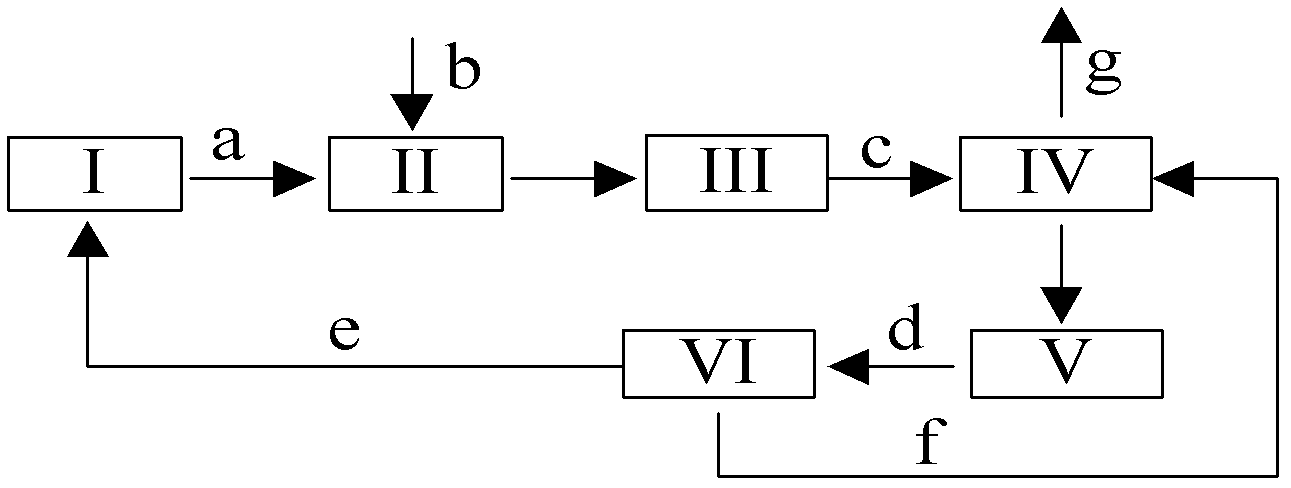

[0022] Such as figure 1 Shown, a kind of treatment system of circulating aquaculture water, comprises culture tank I, adjustment tank II, bioreactor III, buffer tank IV and filter unit VII, culture tank I, adjustment tank II, bioreactor III, buffer tank IV It is connected with the filter unit in turn, and there is a grid in the regulating tank II, and the filter unit VII is composed of a pre-filter device V and a ceramic membrane filter VI. The water port is connected with the ceramic membrane filter VI water inlet, the ceramic membrane filter VI water outlet is connected with the culture tank I water inlet, and the ceramic membrane concentrated solution outlet of the ceramic membrane filter VI is connected with the ceramic membrane concentrated solution inlet of the buffer tank IV. The ceramic membrane pore size of the ceramic membrane filter is 20nm.

Embodiment 2

[0024] This embodiment is basically the same as Embodiment 1, except that the pore diameter of the ceramic membrane filter is 100 nm.

Embodiment 3

[0026] Such as figure 1 As shown, a treatment method for circulating aquaculture water, the circulating water a of the aquaculture tank I enters the regulating tank II, the regulating pond is provided with a grille, and air b is blown into the regulating pond II for aeration, and the effluent of the regulating pond enters the biological reaction The effluent c of bioreactor III and bioreactor III enters the buffer tank IV, the effluent of the buffer tank enters the pre-filter device V, large particles and biological flocs are removed in the pre-filter device V, and the effluent d of the pre-filter device V enters the ceramic membrane with a pore size of 50nm The ceramic membrane filter VI removes colloids, bacteria, spores and other small molecules. The ceramic membrane filter effluent e enters the culture tank VI, the concentrated liquid f returns to the buffer tank, and the concentrated liquid g in the buffer tank IV is discharged regularly. After being treated by the cerami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com