Preparation method for vaterite-phase calcium carbonate microspheres with uniform size

A calcium carbonate and vaterite technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problem of insufficient size uniformity of calcium carbonate microspheres, improve coating properties and filling performance, and the preparation method is simple and fast. , the effect of uniform size and height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Configuration of calcium salt solution: Dissolve 0.5mol of anhydrous calcium chloride in 1L of deionized water to obtain a concentration of 0.5mol L -1 Calcium chloride solution, set aside.

[0043] (2) Configuration of carbonate-containing aqueous solution: Weigh 0.5mol of sodium carbonate solid, dissolve it in 1L deionized water, and obtain a concentration of 0.5mol L -1 Sodium carbonate solution, set aside.

[0044] (3) Configuration of double hydrophilic hyperbranched polymer aqueous solution: weigh 0.5g hyperbranched polymer, dissolve it in 0.5L deionized water, and obtain a concentration of 1g L -1 polymer solution.

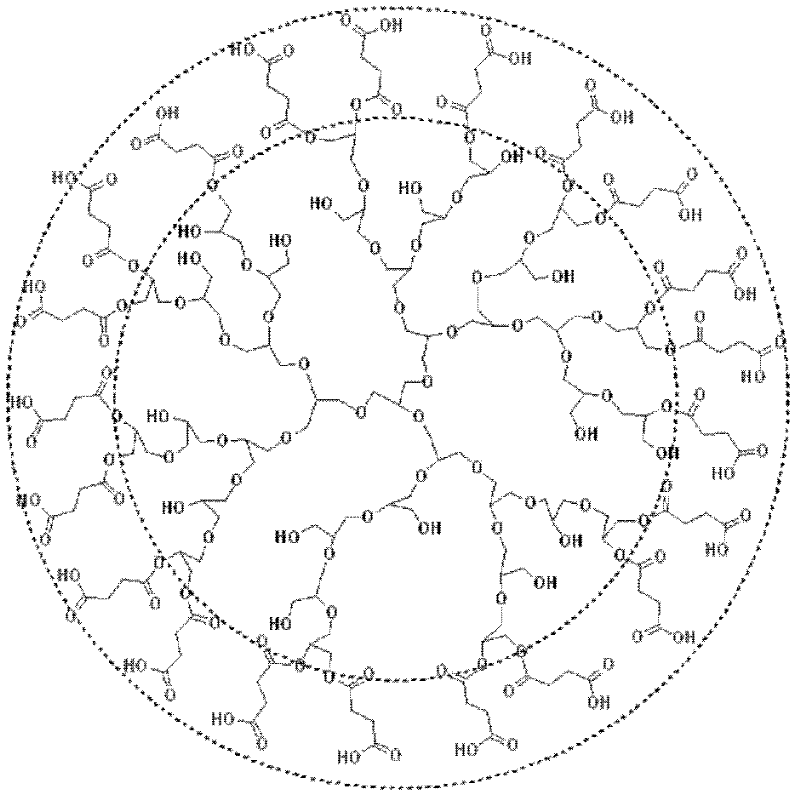

[0045] In this step, the preparation method of hyperbranched polymer is as follows

[0046] (A) Weigh 1 gram of hydroxyl-terminated hyperbranched polyglycidyl ether and dissolve it in 40 mL of anhydrous pyridine, and heat to dissolve. (B) After the solution was cooled to room temperature, 0.85 g of succinic anhydride was added thereto, and th...

Embodiment 2

[0049] Change the configuration of the calcium salt solution in step (1) to: dissolve 0.5 mol of calcium nitrate in 1L of deionized water to obtain a concentration of 0.5 mol L -1 Calcium nitrate solution, set aside.

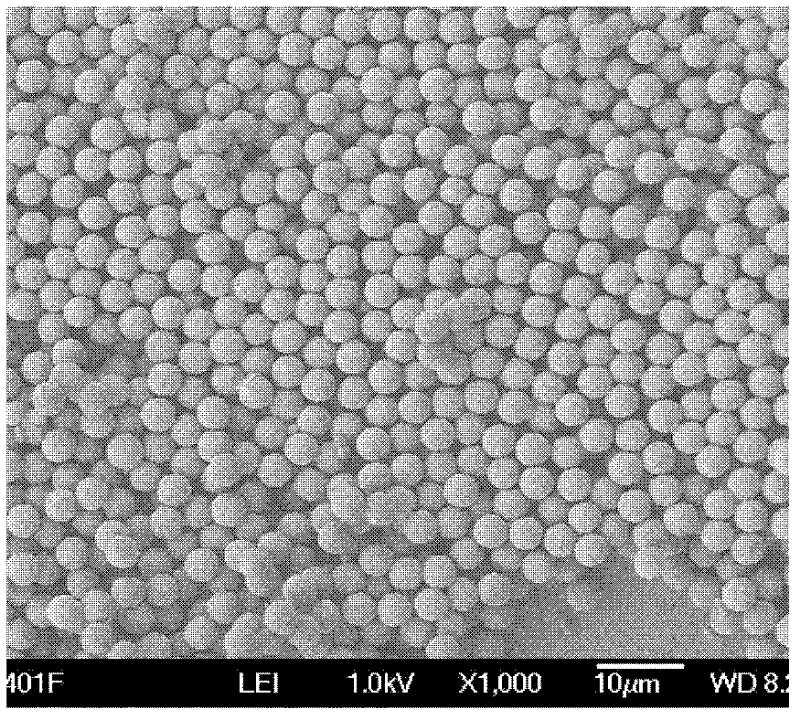

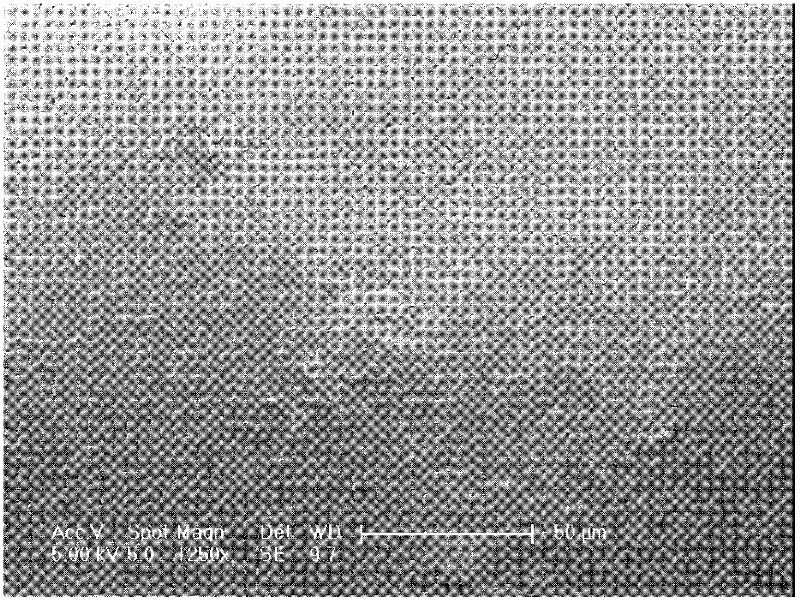

[0050] Subsequent steps are operated with embodiment 1, and white calcium carbonate powder 0.012g is obtained, and the analysis result of gained product is as follows: the calcium carbonate powder that obtains is the spherical particle of size height uniformity, and particle diameter is 3.6 microns, and crystal form is vaterite phase, aggregates The material content is 7wt%.

Embodiment 3

[0052] Change the configuration of the carbonate-containing aqueous solution in step (2) to: Weigh 0.5mol of potassium carbonate solid, dissolve it in 1L deionized water, and obtain a concentration of 0.5mol L -1 Potassium carbonate solution, set aside.

[0053] Other step operation is the same as embodiment 1, makes white calcium carbonate powder 0.012g, and gained product analysis result is as follows: the calcium carbonate powder that obtains is the spherical particle of size height uniformity, and particle diameter is 3.8 microns, and crystal form is vaterite phase, and polymerization The material content is 7wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com