Method for improving strength of aerogel composite material

A complex and gelling technology, which is applied in chemical instruments and methods, silicon compounds, silicon dioxide, etc., can solve the problems of excessive gel volume shrinkage, short aging time at room temperature, and easy shrinkage, etc., to avoid small Too many molecules, meet the requirements of mechanical processing, and improve the effect of reaction polymerization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0060] According to some embodiments of the present invention, the method for preparing a fiber composite silica airgel material includes the following steps:

[0061] 1) Silica sol preparation steps;

[0062] 2) Impregnation step: using the silica sol to impregnate the reinforcing fiber to obtain a silica sol-reinforcing fiber composite;

[0063] 3) Gelation step: gelling the silica sol-reinforced fiber composite at room temperature to obtain a silica wet gel-reinforced fiber composite;

[0064] 4) Aging step: using the aging composition described in the first part of the present invention or the aging method described in the second part of the present invention to age the silicon wet gel-reinforced fiber composite;

[0065] 5) Solvent replacement step: replacing the solvent present in the aged silicon wet gel-reinforced fiber composite with a replacement solvent; and

[0066] 6) Drying step: using a supercritical fluid drying method to dry the silicon wet gel-reinforced fi...

Embodiment 1

[0077] Prepare tetraethyl orthosilicate, absolute ethanol, deionized water, and ammonia water at a molar ratio of 1:10:3:0.0002 to form silica sol, then compound with glass fiber used as reinforcing fiber, gel at room temperature, and then place In the aging solution with a molar ratio of ethyl orthosilicate and tetramethylammonium hydroxide of 1:0.0002, heat at 60°C for 24 hours, place at room temperature for 24 hours, then heat at 70°C for 72 hours, and use ethanol for solvent replacement Afterwards, supercritical CO 2 Dry to obtain a silica airgel composite material. After determination, the 2MPa compressive strength of the fiber composite silicon airgel material at room temperature is 5% (according to the method of GJB 1585A-2004), and the density is 0.25g / cm 3 (According to the method of GB / T13350-2000).

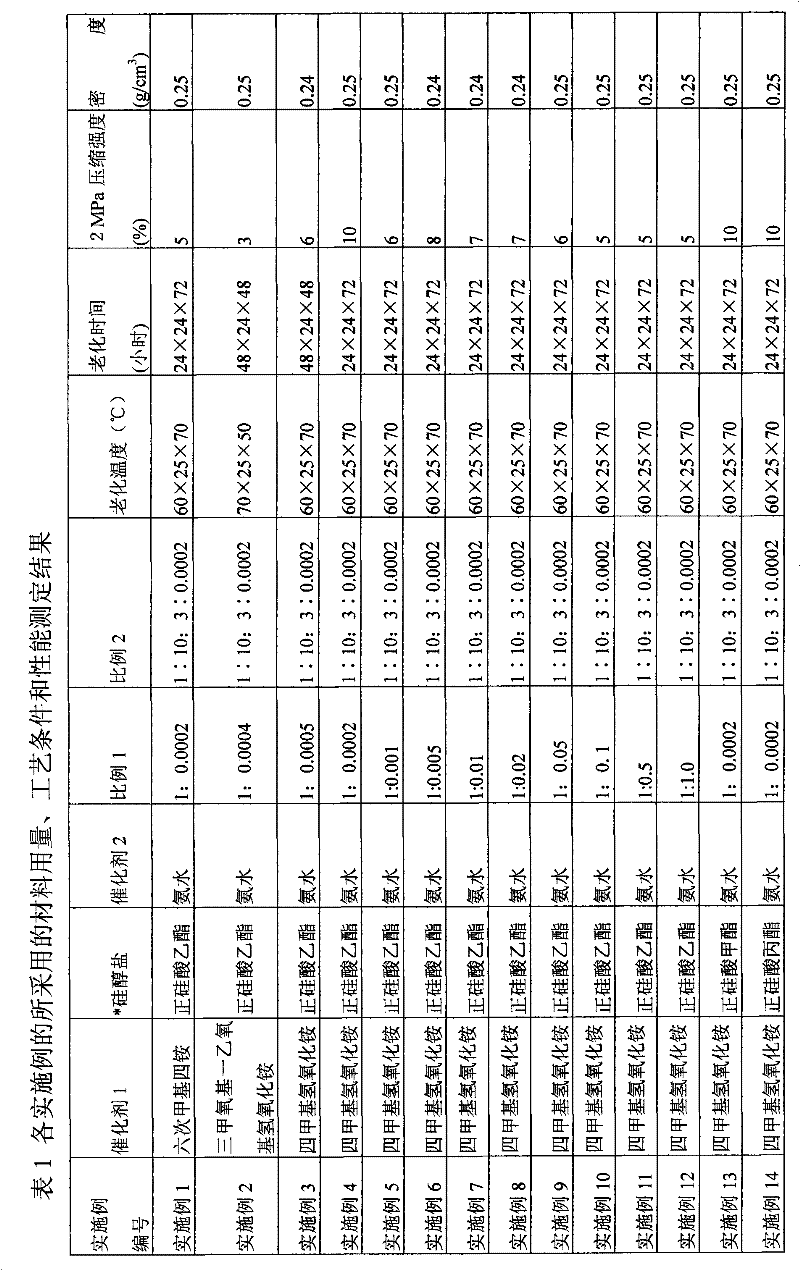

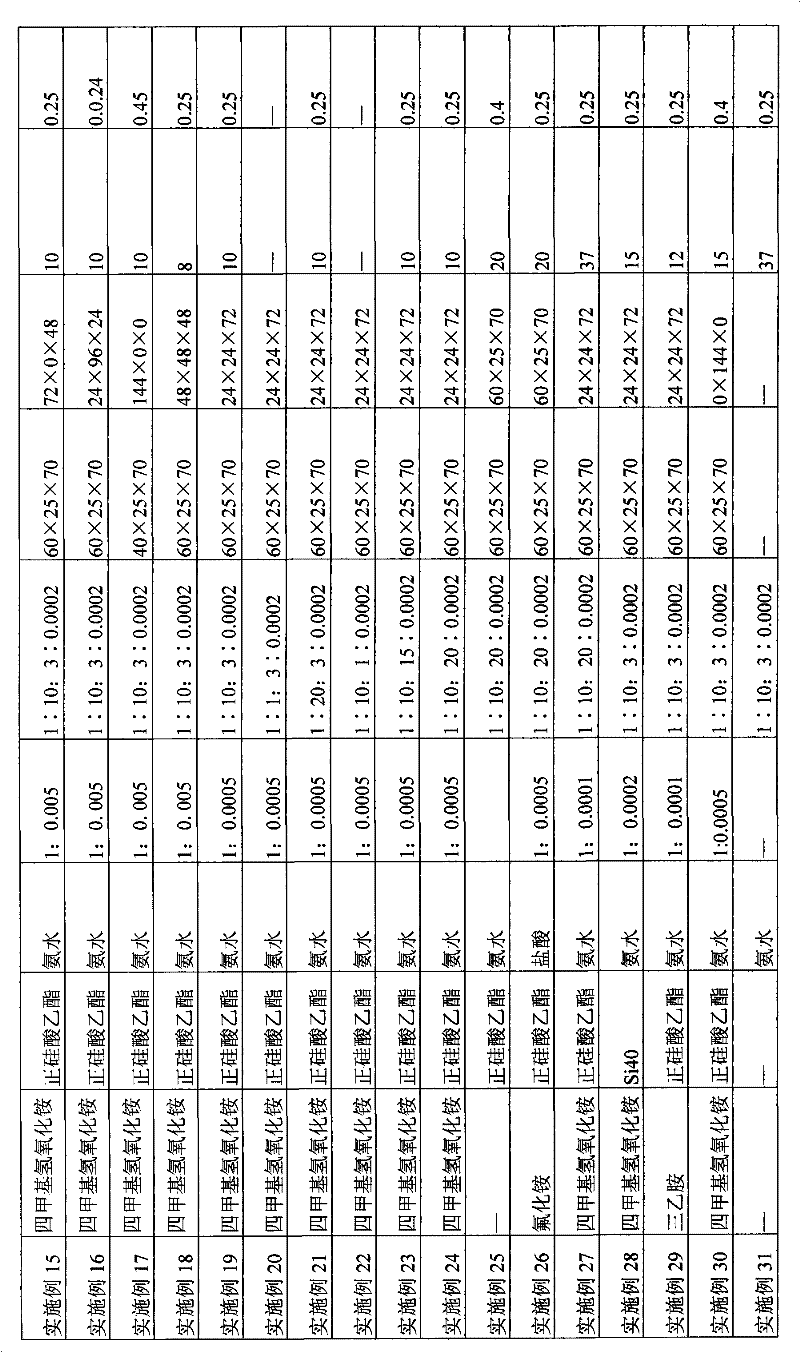

[0078] Except for the contents shown in Table 1 and the appended notes of Table 1, other examples and comparative examples were carried out in the same manner as in E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com