Method for purification of low-purity single-wall carbon nano-tubes

A technology of single-walled carbon nanotubes and a purification method, which is applied in the field of purification of low-purity single-walled carbon nanotubes, can solve the problems of low purification efficiency, long purification period, and difficulty in SWNTs purification, etc., and achieves the effect of small structural damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

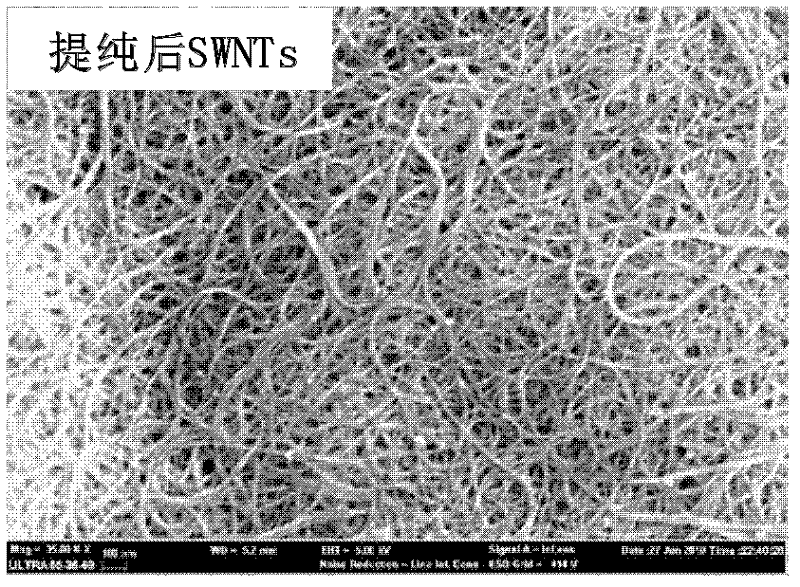

[0028] according to figure 1 In the flow chart shown, 0.5g of low-purity SWNTs initial product was oxidized in air at 370°C for 30 minutes, then added to 2wt% SDS solution for 30 minutes of ultrasonication, and then the uniformly dispersed SWNTs aqueous solution was centrifuged at 9000rpm for 30 minutes; The supernatant was supernatant and ultrasonicated again for 10min, and then centrifuged at 12000rpm for 60min; the obtained single-walled carbon nanotube scanning electron microscope picture was as follows Figure 6 shown. Next, the centrifuged SWNTs supernatant hydraulic filter was washed to remove the SDS surfactant; then the SWNTs product that was filtered out was mixed with 100ml H 2 o 2 Mix and heat at 100°C for 5h. Finally, the SWNTs solution was suction-filtered to neutral and dried to obtain pure SWNTs. Figure 2-5 They are scanning electron microscope photos and transmission electron microscope photos before and after purification, respectively. It can be seen fr...

Embodiment 2

[0030] according to figure 1 In the flow chart shown, 1 g of low-purity SWNTs initial product was oxidized in air at 360°C for 60 minutes, then added to 2wt% SDBS solution for 60 minutes of ultrasonication, and then the uniformly dispersed SWNTs aqueous solution was centrifuged at 6000 rpm for 50 minutes; after centrifugation, the supernatant was taken out liquid and supernatant was ultrasonicated again for 15min, and then centrifuged at 14000rpm for 30min; Figure 7 shown. Next, the SWNTs supernatant hydraulic filter after centrifugation is washed to remove SDBS surfactant; then the SWNTs product that is filtered out is mixed with 200ml 2 o 2 Mix and heat at 100°C for 4h. Finally, the SWNTs solution was suction-filtered to neutral and dried to obtain pure SWNTs. It can be seen from the scanning electron microscope photos of the products obtained under different centrifugation speeds that choosing different centrifugation speeds can effectively remove impurity particles, w...

Embodiment 3

[0032] according to figure 1 In the flow chart shown, 1.2g of low-purity SWNTs initial product was oxidized in air at 400°C for 30 minutes, then added to 1wt% SDS solution for 30 minutes of ultrasonication, and then the uniformly dispersed SWNTs aqueous solution was centrifuged at 6000rpm for 40 minutes; Supernatant and supernatant were sonicated again for 20min, and then centrifuged at 12000rpm for 30min; then the centrifuged SWNTs supernatant was hydraulically filtered to remove the SDS surfactant; 2 o 2 Mix and heat at 100°C for 8h. Finally, the SWNTs solution was suction-filtered to neutral and dried to obtain pure SWNTs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com