Parallel noodle-falling bucket device in production line for fresh wet rice noodles

A production line and rice noodle technology, applied in packaging and other directions, can solve the problems of occupying workshop space, affecting work efficiency, increasing production costs, etc., and achieving the effects of low equipment manufacturing and use costs, improving production efficiency, and reducing overall energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

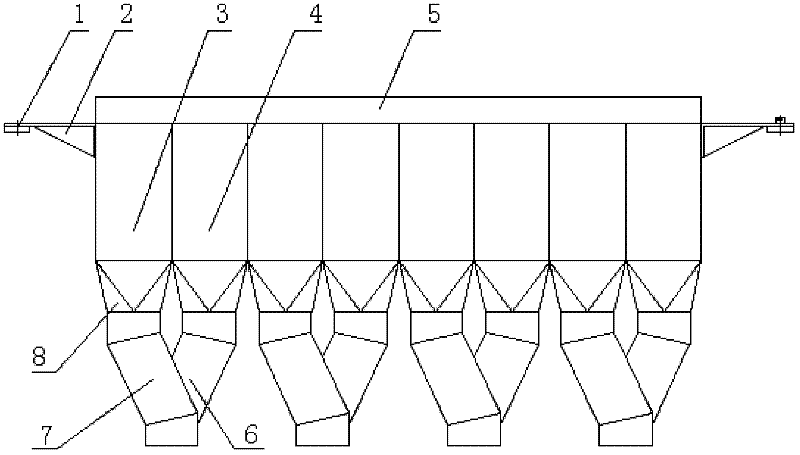

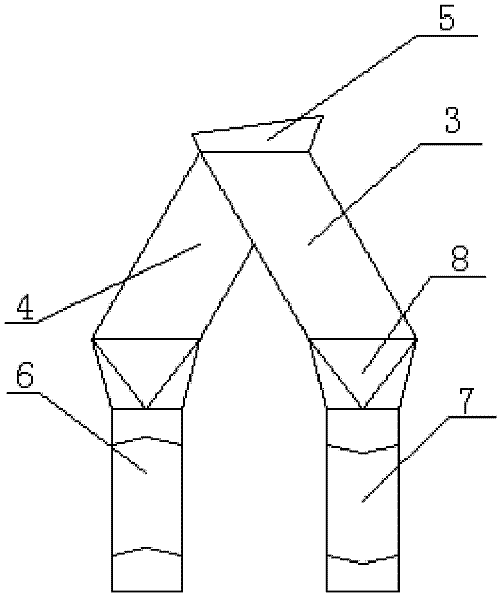

[0015] A side-by-side falling hopper device for a fresh and wet rice noodle production line. Two adjacent funnel hoppers constitute the same drain hopper, and the outlets of the same drain hopper are located in a row of front and back, and one of the same drain hoppers is sequentially composed of a forward section 3 and a vertical section 8 from top to bottom. and right-inclining section 7, and the other from top to bottom is composed of a backward-inclining section 4, a vertical section, and a left-inclining section 6. The left-inclining section and the right-inclining section of the same drainage hopper are respectively 155° from the vertical section. . Supports are symmetrically installed on both sides of the receiving hopper, and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com