Super long automatic welding equipment and method for multiple layers of composite metal filter screens

A metal screen and automatic welding technology, applied in welding equipment, metal processing equipment, resistance welding equipment, etc., can solve the problem of loose bonding, uneven quality of sand filter pipes, and no ultra-long automatic welding of multi-layer composite metal screens. equipment and methods to ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

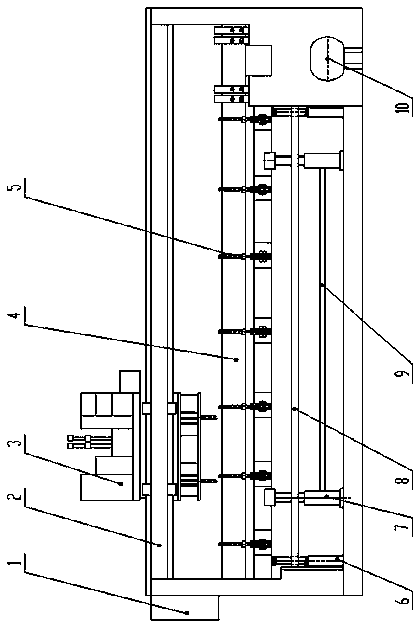

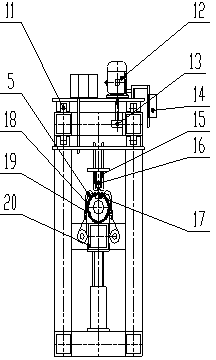

[0018] combined with Figure 1-2 , to further describe the present invention:

[0019] The present invention mainly consists of a power supply assembly 1, a bed 2, a trolley travel assembly 3, a mandrel 4, an automatic reel arm 5, a floating support 6, a supporting cylinder 7, a tight connecting rod 8, a supporting connecting rod 9, and an air circuit System 10, guide rail 11, transmission system 12, position controller 13, programmable controller CRT operation panel 14, auxiliary pressing rod 15, DC controllable welding electrode 16, mandrel conductive block 17, reel arm chain 18, be The welding workpiece 19 and the lower support body 20 are composed. The top of the bed 2 is provided with a trolley assembly 3, the trolley assembly 3 moves through the guide rail 11, the DC controllable welding electrode 16 and the auxiliary pressing rod 15 are installed at the lower part of the trolley assembly 3; One end is fixed on one side of the bed, and the conductive block 17 of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com