Preparation method of magnetic composite nanomaterial , product prepared by the method, and application thereof

A composite material and magnetic nanotechnology, applied in the direction of alkali metal compounds, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of large separation of fluorine ions, easy aggregation of nanoparticles, and reduction of adsorption capacity, etc., to achieve preparation The method is simple, the cost is low, and the effect of improving the adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

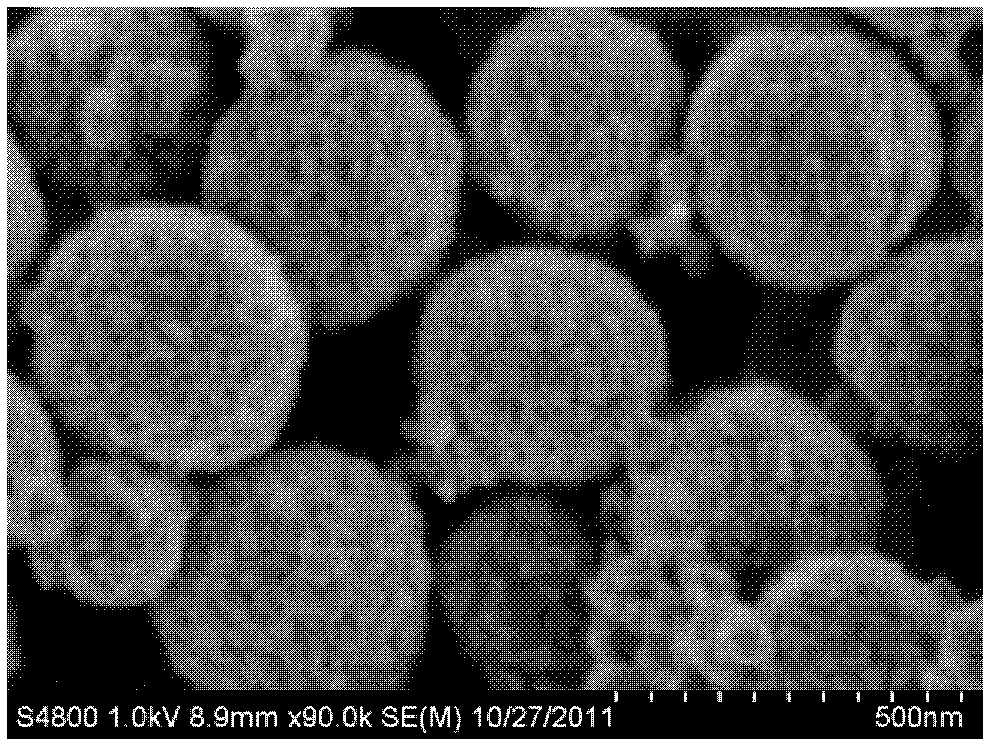

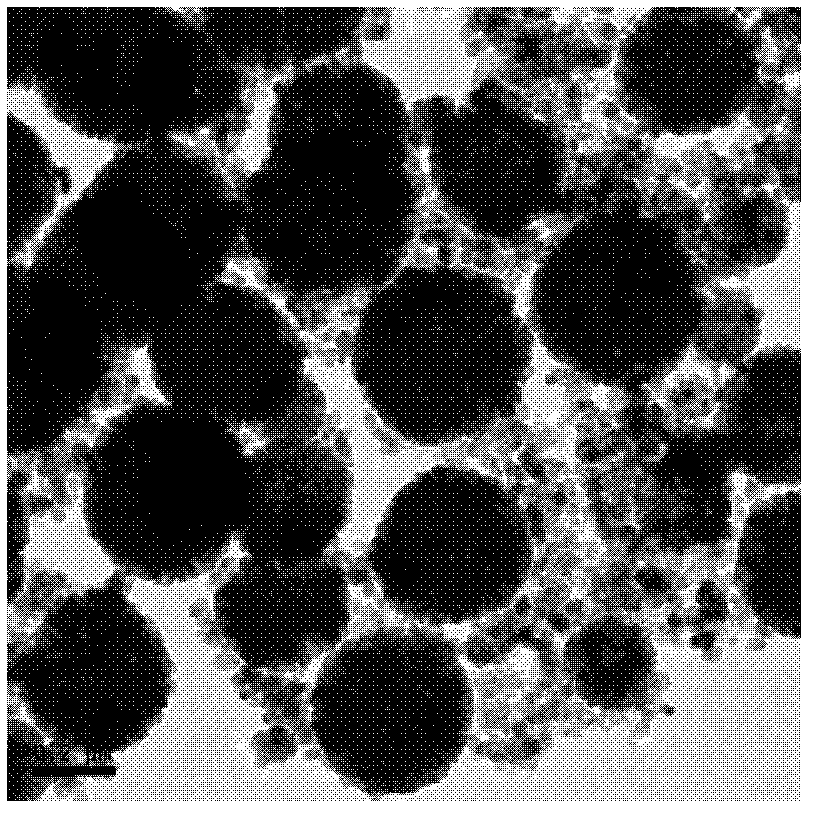

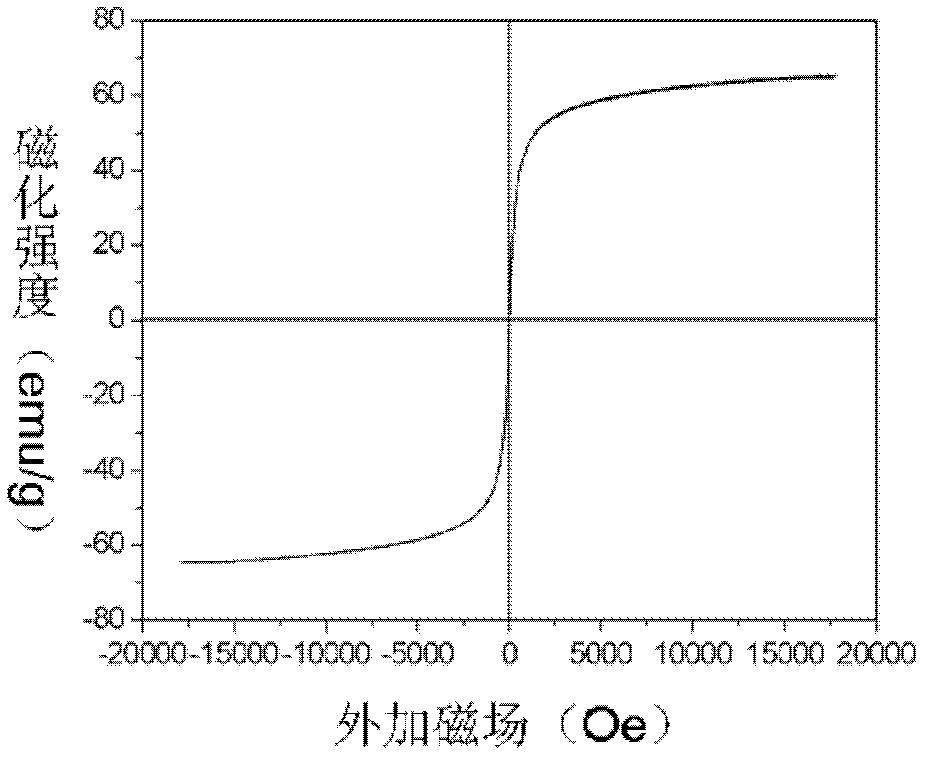

[0036] (1) 1.0g Fe(NO 3 ) 3 and 2.67g sodium citrate are dissolved in 37ml ethylene glycol respectively, and the mass ratio is 1: 2.67, wherein the mass concentration of inorganic iron salt and citrate is 10%, after mixing, move into stainless steel to add polytetrafluoroethylene reaction kettle In the process, the reaction kettle was tightened, heated to 180° C., and reacted for 8 hours to obtain an inorganic magnetic microsphere solution.

[0037] (2) The inorganic magnetic microsphere solution that step (1) is obtained is dispersed in 370ml deionized water, and the volume ratio of inorganic magnetic microsphere solution and deionized water is 1: 10, utilizes magnetic field to separate washing, then disperses in 0.05mol / In L sulfuric acid solution, sonicate for 10min, then use magnet to separate out the magnetic microspheres treated with strong acid, and wash 3 times with deionized water; then add in the mixed solution of ethanol and water, the volume ratio of ethanol and ...

Embodiment 2

[0043] (1) 0.80g FeCl 3 ·6H 2 O and 2.4g sodium citrate are dissolved in 32ml ethylene glycol respectively, and the mass ratio is 1: 3, wherein the mass concentration of inorganic iron salt and citrate is 10%, after mixing, move into stainless steel to add polytetrafluoroethylene reaction kettle In the process, the reaction kettle was tightened, heated to 250° C., and reacted for 8 hours to obtain an inorganic magnetic microsphere solution.

[0044] (2) The inorganic magnetic microsphere solution that step (1) is obtained is dispersed in 160ml deionized water, and the volume ratio of inorganic magnetic microsphere solution and deionized water is 1: 5, utilizes magnetic field to separate washing, then disperses in 0.15mol / In L hydrochloric acid solution, sonicate for 40min, then use magnet to separate the magnetic microspheres through strong acid treatment, and wash 5 times with deionized water; then add in the mixed solution of ethanol and water, the volume ratio of ethanol ...

Embodiment 3

[0050] (1) 1.60g FeCl 3 ·6H 2 O and 4.0 sodium citrate are respectively dissolved in 56ml of ethylene glycol, the mass ratio is 2:5, wherein the mass concentration of inorganic iron salt and citrate is 10%, add in the reactor and mix, heated to 200°C, react The time is 8h, and the inorganic magnetic microsphere solution is obtained;

[0051] (2) The inorganic magnetic microsphere solution that step (1) is obtained is dispersed in 560ml deionized water, and the volume ratio of inorganic magnetic microsphere solution and deionized water is 1: 10, utilizes magnetic field to separate washing, then disperses in 0.05mol / In L hydrochloric acid solution, ultrasonically act for 10 minutes, then use a magnet to separate the magnetic microspheres treated with strong acid, and wash them with deionized water for 3 to 5 times; then add them to the mixed solution of ethanol and water, the volume ratio of ethanol and water is 1:1, under stirring, add sodium hydroxide to adjust the pH to 9....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com