Integrated exhaust gas recovery device

A waste gas recovery and integrated technology, applied in the direction of vapor condensation, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as difficult work, save on-site design and on-site construction, shorten project construction period, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

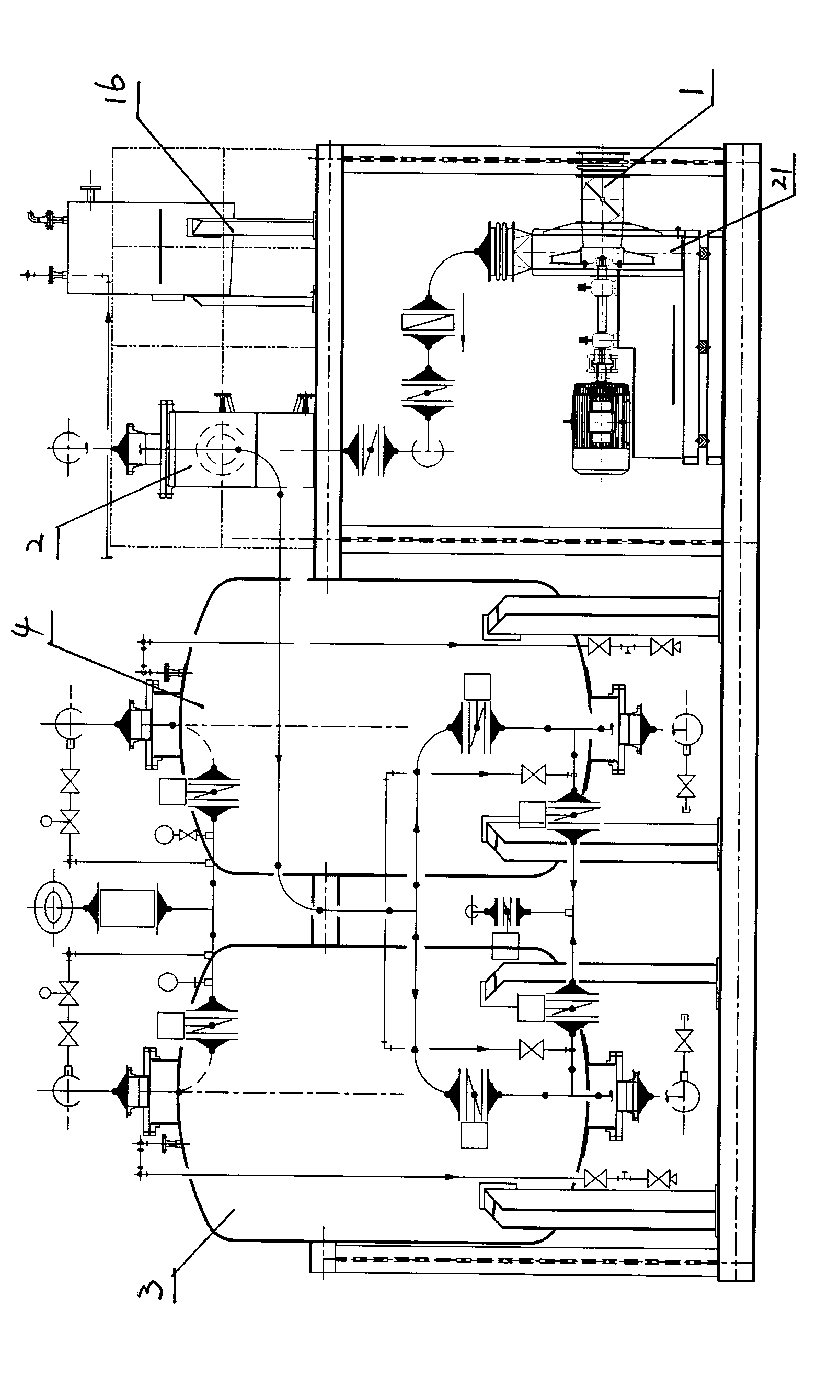

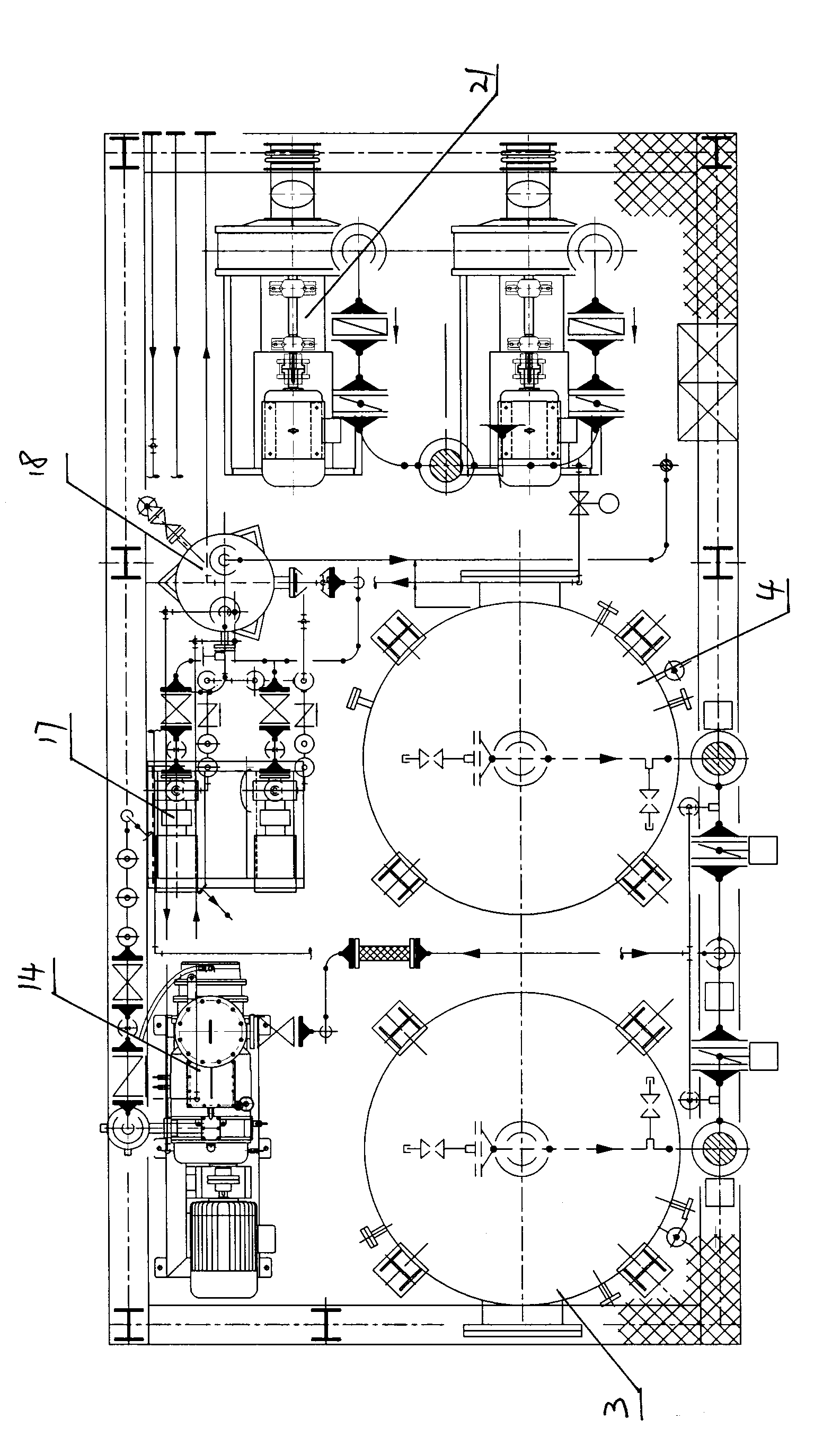

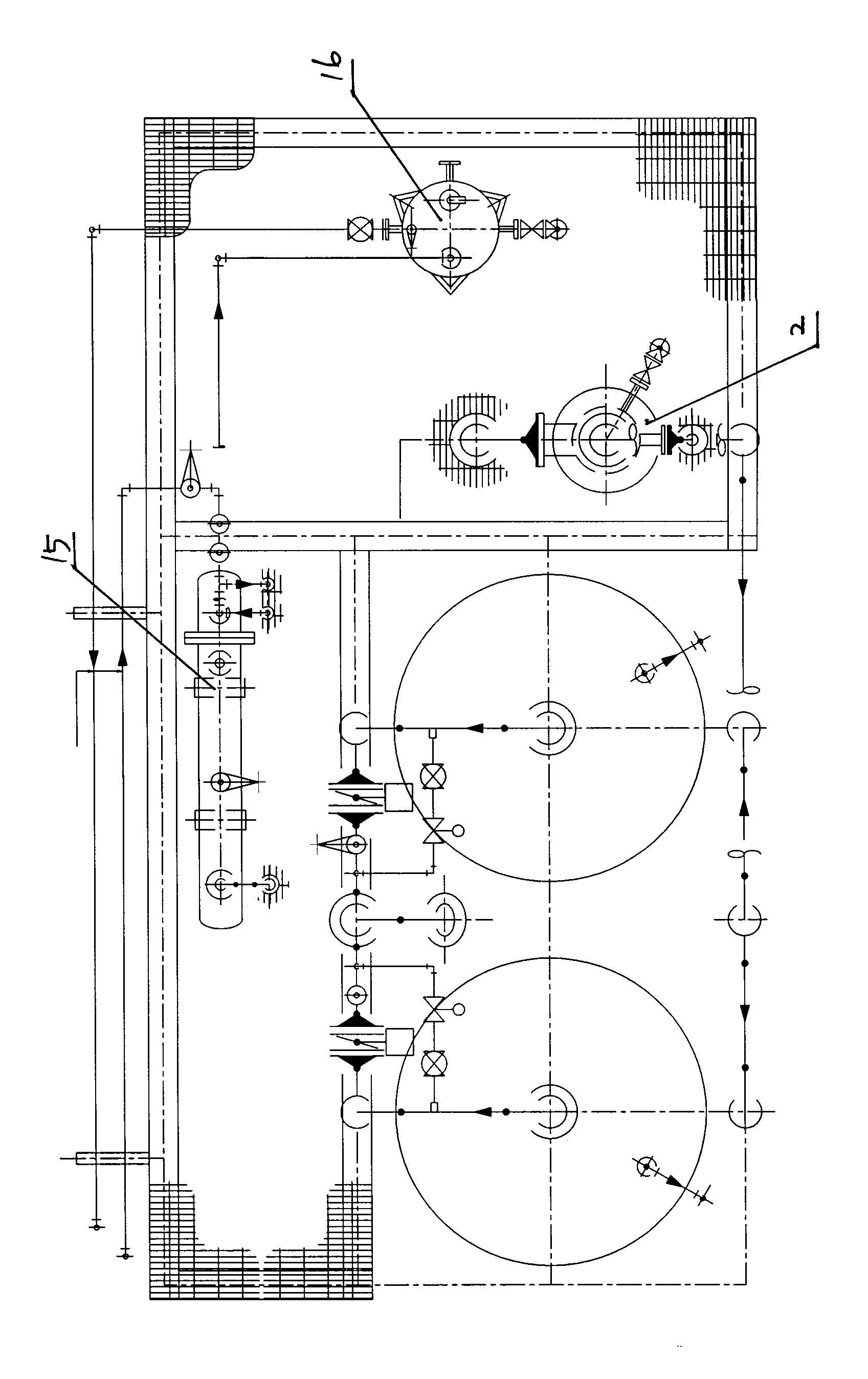

[0014] An integrated exhaust gas recovery device, which is provided with an integrated frame, and an oil gas recovery main pipe 1, a pressurized blower unit 21, a gas-liquid separator 2, an adsorption tower, a vacuum pump 14, a water-cooled heat exchanger 15, and a circulation system are arranged in the frame Refrigeration unit 16, recovery tank 18 and liquid discharge pump group 17, the adsorption tower is arranged at the front of the frame, the frame on one side of the adsorption tower is divided into upper and lower layers by side partitions, and the pressurized blower group is arranged at the side partition In the frame below the plate, the gas-liquid separator and circulating refrigeration unit are arranged on the upper part of the side partition, the frame at the rear of the adsorption tower is divided into upper and lower layers by the rear partition, and the vacuum pump, recovery tank and liquid drainage pump group are arranged In the frame below the rear bulkhead, a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com