Ventilative shape-fixed compound tip sticks and preparation method thereof

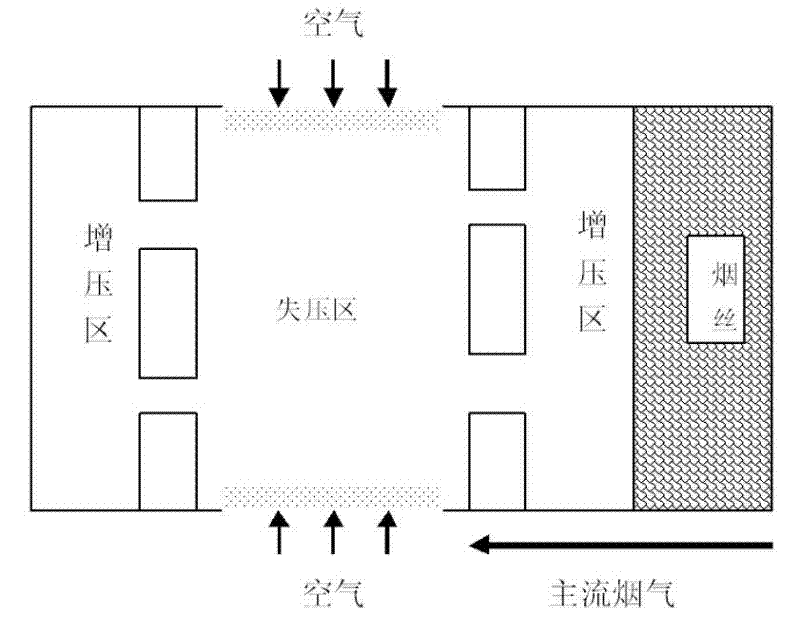

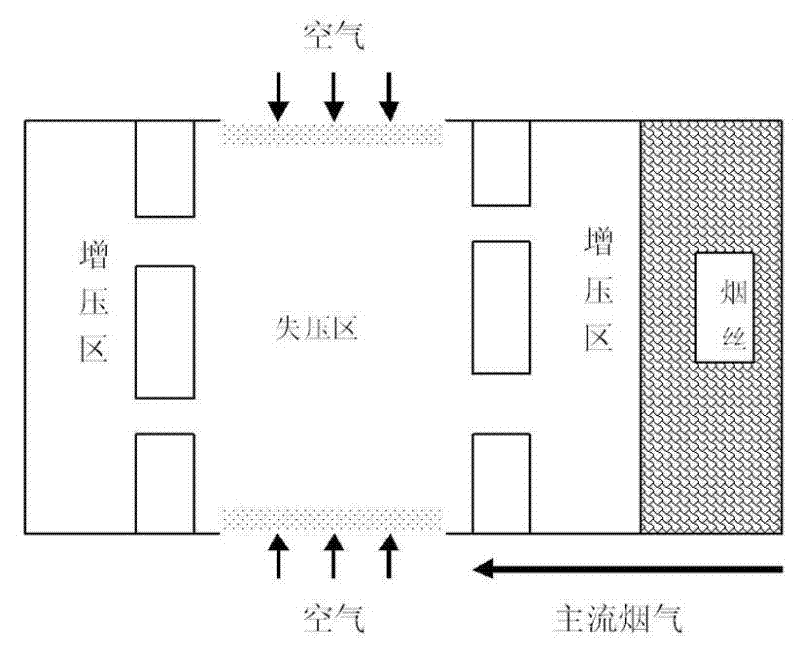

A technology of mouth rod and filter rod, which is applied in the design and manufacture of new cigarette filter rods, can solve the problems of limited length, bottleneck of coke reduction and harm reduction, and poor performance of cigarette smoke dilution and settlement, etc., to increase ventilation High efficiency, convenient industrial application, and good dilution characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A ventilated solid-shaped nozzle made by the following process

[0027] a. Raw materials: Screen one or more of PLA, PVC, PCL that is non-polluting, biodegradable, and the color is between transparent and translucent;

[0028] b. The material initially melts and the temperature reaches the melting point of the raw material;

[0029] c. Add plasticizers, modifiers, etc. to the raw materials at a certain ratio of 1:1;

[0030] d. Stir evenly, so that the raw materials and auxiliary materials are evenly mixed;

[0031] e. The raw material obtained in step d is injection-molded according to the design drawing of the solid nozzle stick;

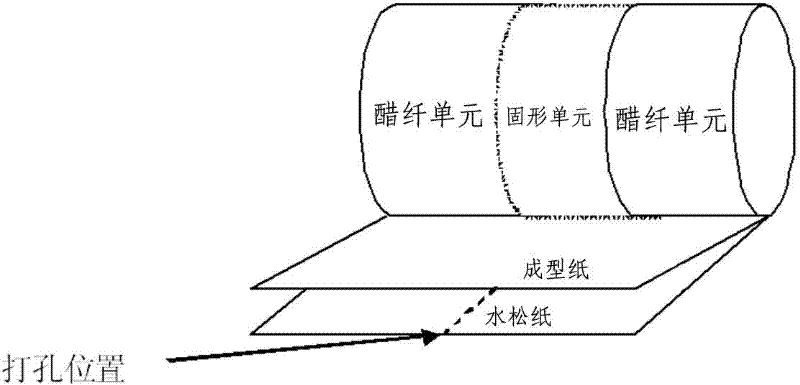

[0032] f. Add the formed solid nozzle to the filter rod to form a composite nozzle;

[0033] g. Laser perforate the tipping paper of the solid unit section in the composite nozzle rod.

[0034] Choose one or more of PLA, PVC, PCL as raw materials, add glycerol triacetate and citrate and mix for 30min under normal temperature and pressure, the mixing rat...

Embodiment 2

[0036] A ventilated solid-shaped nozzle made by the following process

[0037] a. Raw materials: Screen one or more of PLA, PVC, PCL that are non-polluting, biodegradable, and the color is between transparent and translucent;

[0038] b. The material initially melts and the temperature reaches the melting point of the raw material;

[0039] c. Add plasticizers and modifiers to the raw materials in a certain ratio of 1:2;

[0040] d. Stir evenly, so that the raw materials and auxiliary materials are evenly mixed;

[0041] e. The raw material obtained in step d is injection-molded according to the design drawing of the solid nozzle stick;

[0042] f. Add the formed solid nozzle to the filter rod to form a composite nozzle;

[0043] g. Laser perforate the tipping paper of the solid unit section in the composite nozzle rod.

[0044] Choose one or more of PLA, PVC, PCL as raw materials, add triacetin and epoxy soybeans and mix for 30 minutes at room temperature and pressure, the mixing ratio is...

Embodiment 3

[0046] A ventilated solid-shaped nozzle made by the following process

[0047] a. Raw materials: Screen one or more of PLA, PVC, PCL that are non-polluting, biodegradable, and the color is between transparent and translucent;

[0048] b. The material initially melts and the temperature reaches the melting point of the raw material;

[0049] c. Add plasticizers and modifiers to the raw materials in a certain ratio of 1:3;

[0050] d. Stir evenly, so that the raw materials and auxiliary materials are evenly mixed;

[0051] e. The raw material obtained in step d is injection-molded according to the design drawing of the solid nozzle stick;

[0052] f. Add the formed solid nozzle to the filter rod to form a composite nozzle;

[0053] g. Laser perforate the tipping paper of the solid unit section in the composite nozzle rod.

[0054] Choose one or more of PLA, PVC, PCL as raw materials, add glycerol triacetate and acetyl tricaprylate citrate and mix for 30 minutes at room temperature and pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com