Optical element surface defect detecting system based on active laser beam scanning

A technology of optical components and detection systems, applied in the field of optoelectronics, can solve the problems of online monitoring of surface defects of large-diameter optical components, complex application environments, and damage of monitoring equipment, etc., to overcome environmental adaptability problems and simple system structure , the effect of taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

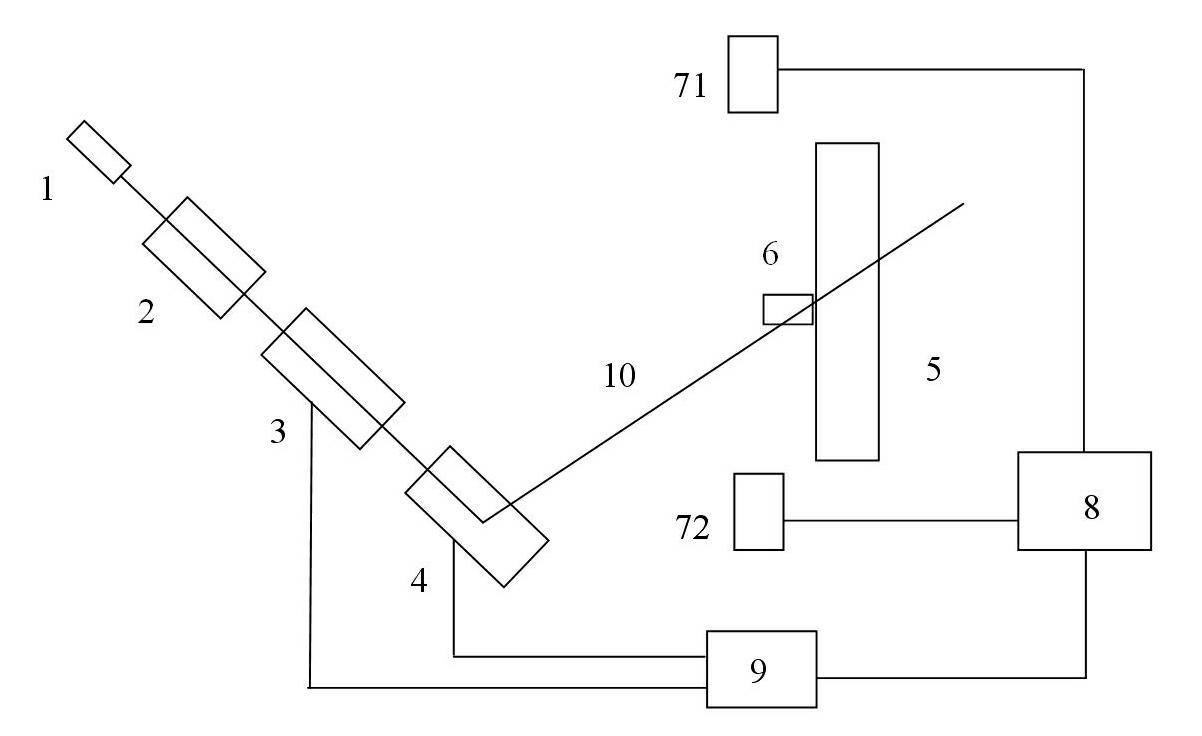

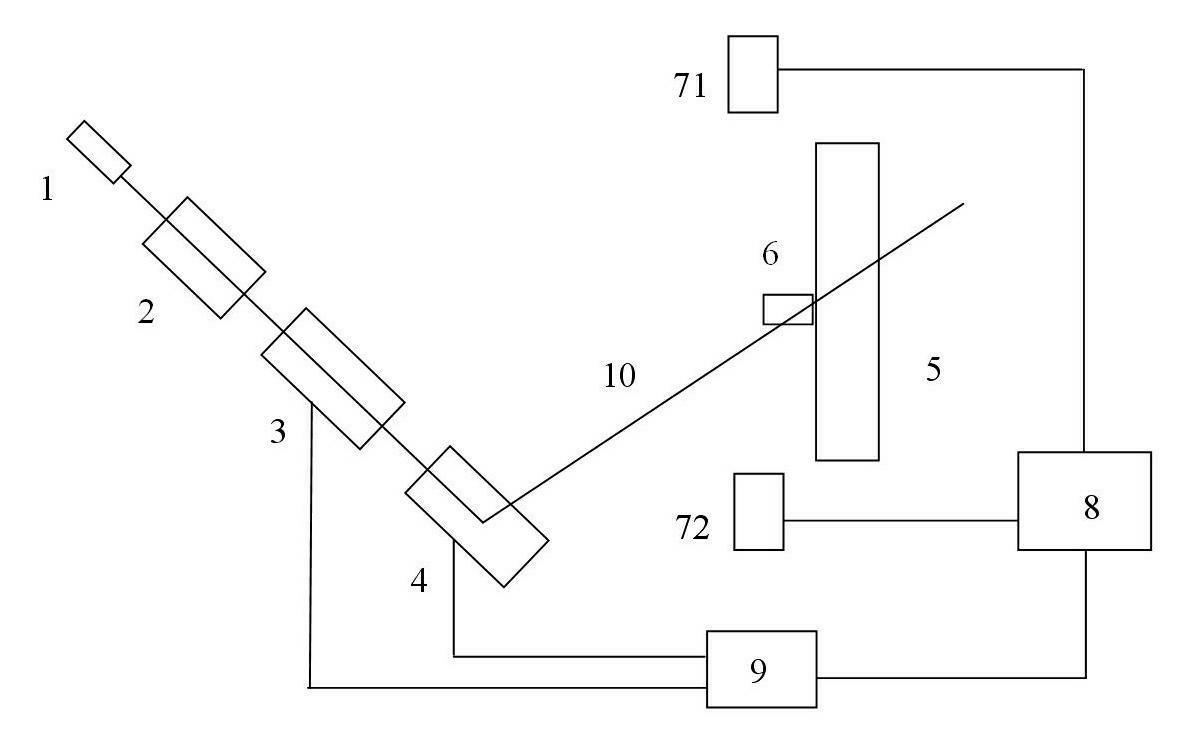

[0014] figure 1 It is a structural schematic diagram of an optical element surface defect detection system based on laser beam active scanning of the present invention. exist figure 1 Among them, an optical element surface defect detection system based on laser beam active scanning of the present invention includes a laser 1 , a beam expander 2 , a zoom lens 3 , a guide mirror 4 , a photoelectric probe, a computer 8 and a controller 9 . Among them, the laser 1, the beam expander 2, the zoom lens 3, and the guide mirror 4 are arranged in sequence; Fixed, the photoelectric probe is arranged outside the light-passing area of the optical element 5; in the present embodiment, the photoelectric probe is set to two, namely the photoelectric probe I 71 and the photoelectric probe II 72, and the photoelectric probe I 71 and the photoelectric probe II 72 are respectively externally connected to the computer 8; control The controller 9 is connected with the computer 8, and the contro...

Embodiment 2

[0018] The basic structure of this embodiment is the same as that of Embodiment 1, and the difference is that the photoelectric probes are set to 12, and the 12 photoelectric probes are evenly distributed around the optical element 5, and the photoelectric probes detect scattered light from different angles, thereby improving The detection precision and accuracy of the equipment.

Embodiment 3

[0020] The basic structure of this embodiment is the same as that of Embodiment 1, except that the photoelectric probe can be a photomultiplier tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com