Method for measuring enzyme substrate amount by combining enzyme reaction process method and terminal balance method

A technology of reaction end point and end point balance, which is applied in the preparation of test samples, color/spectral characteristic measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

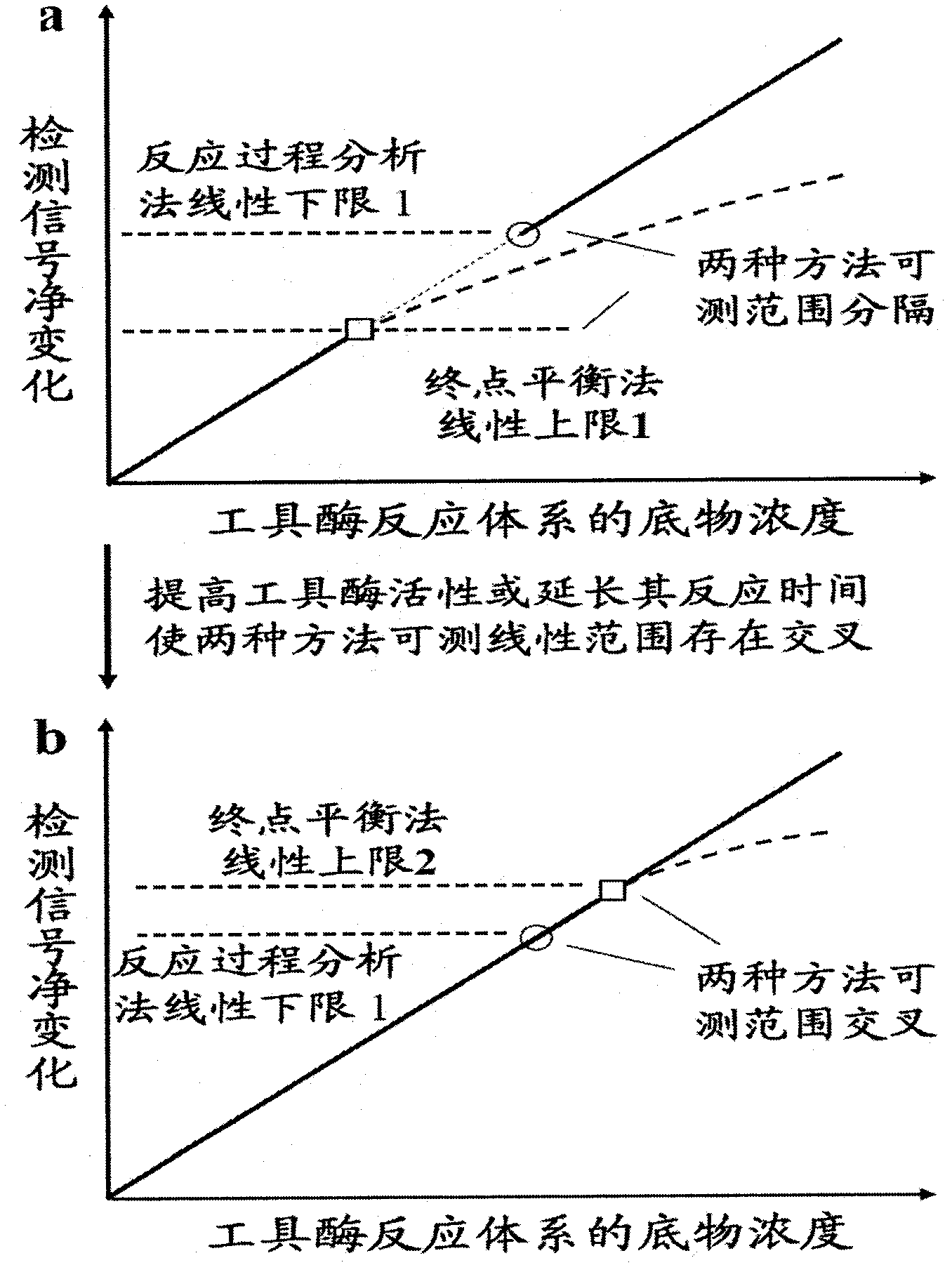

Problems solved by technology

Method used

Image

Examples

Embodiment 1

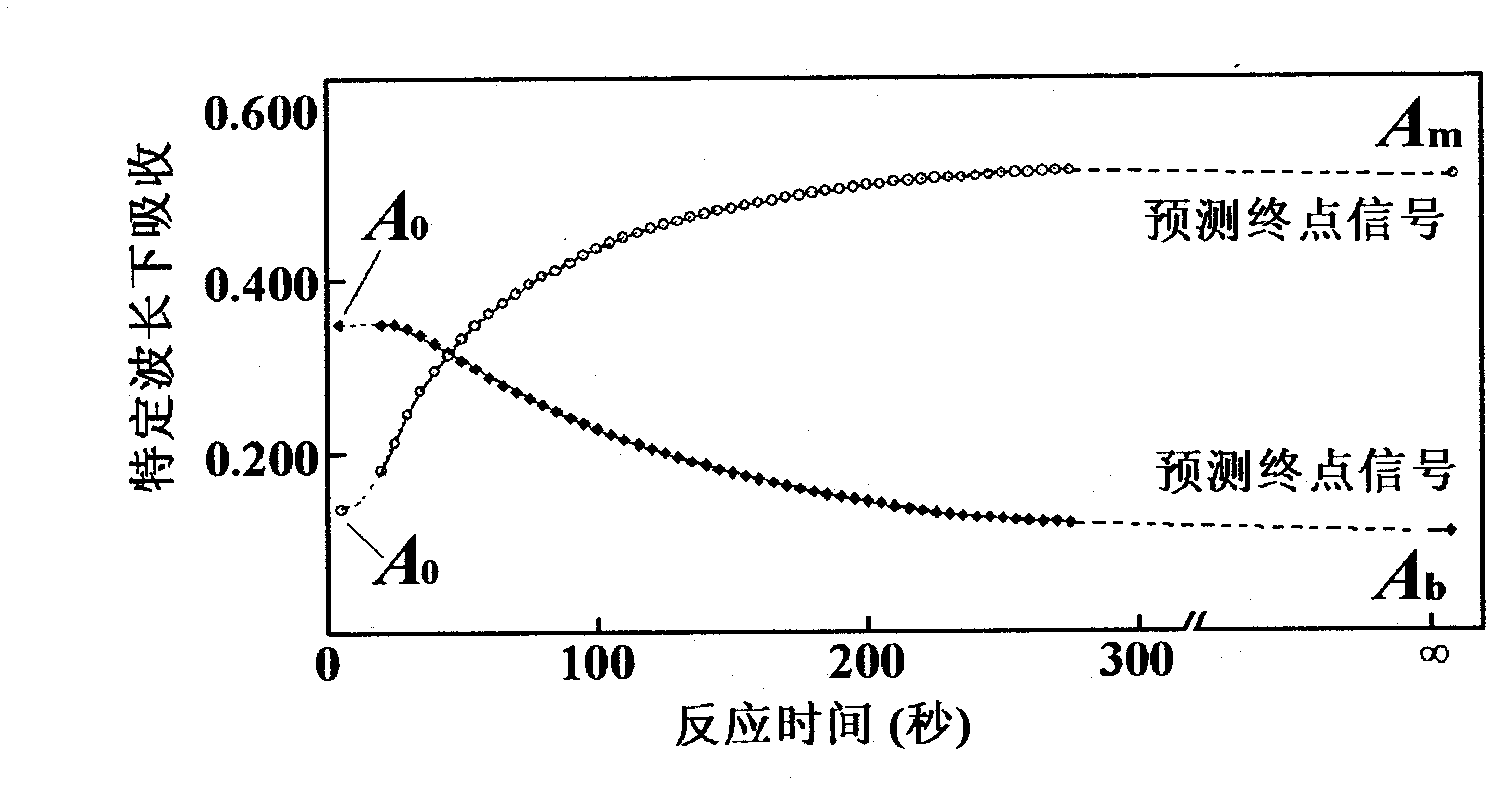

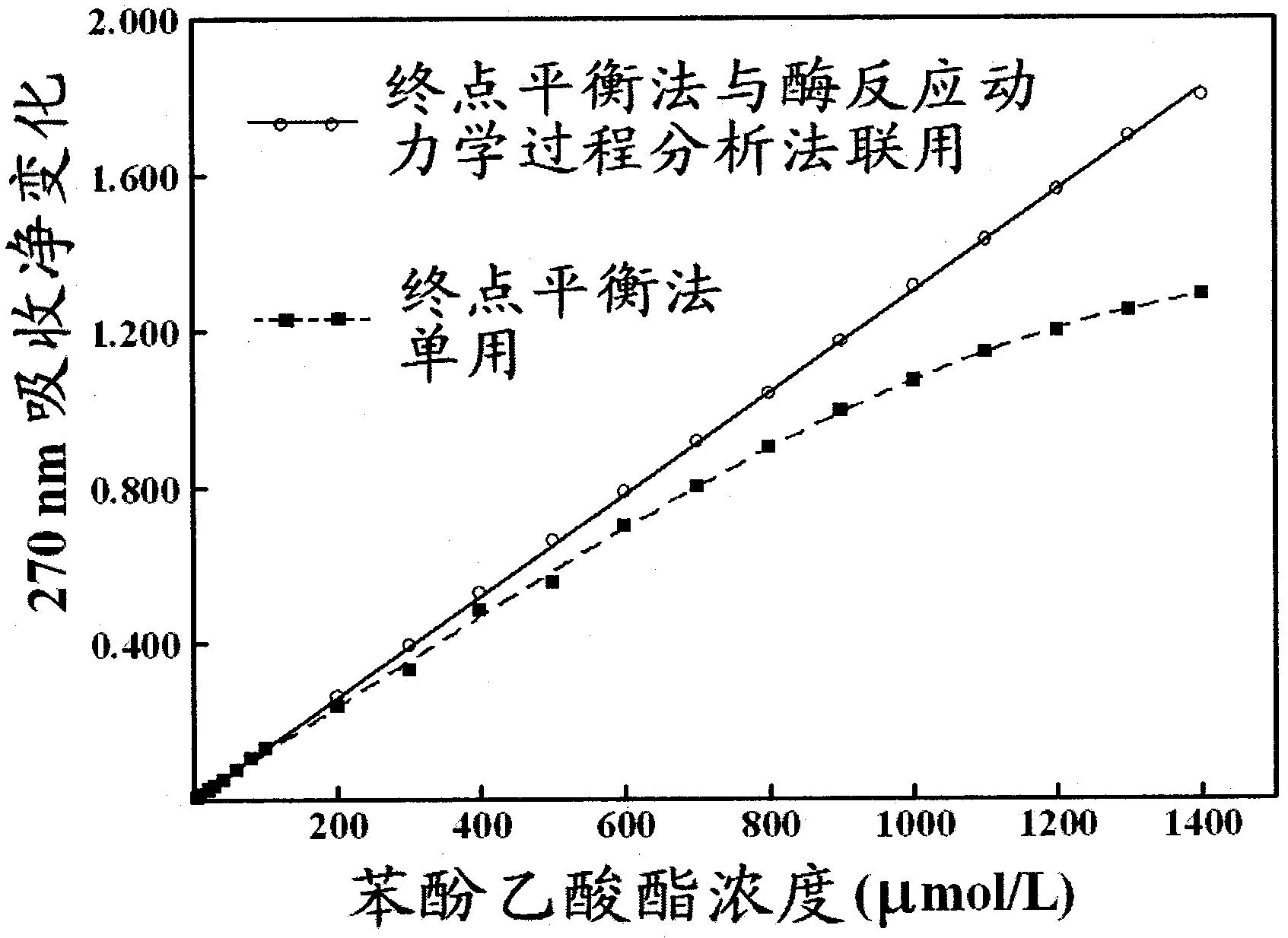

[0034] Embodiment 1: Determination of phenol acetate by joint end-point equilibrium method and enzyme reaction kinetics process analysis method

[0035] Human serum was precipitated by 85% ammonium sulfate, the aromatic esterase in the precipitate was dissolved in 50mmol / L Tris-HCl buffer, and DEAE-cellulose ion exchange chromatography was equilibrated with the same buffer, 0.10mol / L to 1.0mol / L NaCl Concentration gradient elution and purification; phenol acetate passed through a 60-mesh silica gel column to remove impurities that inhibit human serum aromatase; after purification of human serum aromatase, phenol acetate was determined at 20U / L; its enzymatic analysis Determination of phenol acetate operating steps are as follows:

[0036] (1), add 2.0mmol / L CaCl in the test tube 2 A total of 0.90ml of 50mmol / L Tris-HCl buffer solution (pH 7.4) and 100μl of phenol acetate aqueous solution samples of different concentrations were kept in a water bath at 25°C for 5 minutes and t...

Embodiment 2

[0045] Embodiment 2: Determination of ethanol by joint end-point equilibrium method and enzyme reaction kinetics process analysis method

[0046] The alcohol dehydrogenase reaction buffer used is 0.20mol / L sodium pyrophosphate (containing 75.0mmol / L semicarbazide, pH 9.2, NAD + The final concentration is 3.0mmol / L; the detailed setting is the same as the literature Anal Sci, 2007, 23 (4): 439-444); the yeast alcohol dehydrogenase (A7011) final concentration of Sigma Company used is 50U / L; The data processing method when the reaction process analysis method predicts the absorption of the end point of the reaction is completely the same as the literature (Anal Sci, 2007, 23 (4): 439-444); the representative operation steps in its application are as follows:

[0047] (1), add the above-mentioned NAD-containing protein in the test tube + Sodium pyrophosphate buffer 1.380ml and sample 100μl, after 5 minutes at 25°C water bath, transfer the above solution as completely as possible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com