Graphene-based strain measuring and motion sensing device and manufacturing method thereof

A technology of motion sensing and strain measurement, applied in measuring devices, electromagnetic measuring devices, electric/magnetic solid deformation measurement, etc., can solve the problems of fatigue aging, poor mechanical properties, etc., and achieve small influence, stable structure, and preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

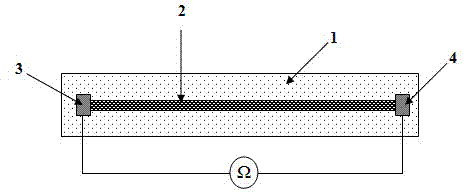

[0050] In the first step, make as Figure 1A Graphene strain measurement device

[0051]1. Vapor-phase chemical deposition of graphene: use 25 micron thick copper foil as the substrate, cut the copper foil into 0.5cm*10cm strips, maintain the growth temperature at 1000°C, feed methane and hydrogen, the gas flow rate is 25sccm methane, 10sccm hydrogen, After growing for 15 minutes, turn off the methane, and quickly cool to room temperature under the protection of 10 sccm hydrogen gas flow, and obtain a graphene material with 1-2 layers on the copper.

[0052] 2. Transfer graphene to polydimethylsiloxane (PDMS) flexible substrate: suspend the surface of the copper sheet covered with graphene with PDMS solution, and soak the copper sheet in 0.1M ferric chloride solution after the solvent evaporates , after 24 hours, the copper was completely dissolved, resulting in a graphene-PDMS layer floating on the solution.

[0053] 3. Coat the two ends of the long side of the graphen...

Embodiment 2

[0060] Graphene is prepared according to the method of implementation example 1.

[0061] The substrate uses polymethyl methacrylate (PMMA) instead of PDMS to transfer the graphene off the copper and transfer it to a polyethylene terephthalate (PET) plastic substrate: the graphene-covered Coat the surface of the copper sheet with PMMA solution. After the solvent volatilizes, place the copper sheet in 0.1M ferric chloride solution and soak it. After 24 hours, the copper is completely dissolved, and a graphene-PMMA tape floating on the solution is obtained; attach the tape On the pre-made strip-shaped PET substrate, then wash off the PMMA with acetone to obtain graphene attached to the PET substrate.

[0062] Magnetron ion sputtering gold electrodes (5nm titanium / 30nm gold) were used at both ends of the graphene long side, and wires were drawn out. The electrodes at both ends of the graphene are encapsulated and protected with sealing silica gel.

[0063] Connect the PET base ...

Embodiment 3

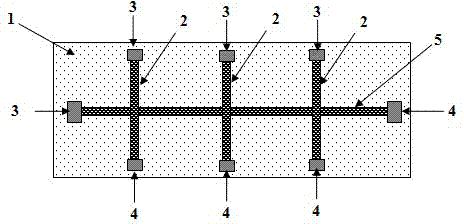

[0066] made as Figure 1B The graphene strain measurement device, the steps are as follows

[0067] 1. Graphene is vapor-phase chemically deposited as in Example 1, except that 0.5cm*10cm and 0.3*3cm copper foils are used as growth substrates.

[0068] 2. Transfer graphene to PET flexible substrate. Suspend the surface of the copper sheet covered with graphene with PMMA solution. After the solvent evaporates, place the copper sheet in 0.1M ferric chloride solution and soak it. After 24 hours, the copper is completely dissolved and the graphene-PMMA strips floating on the solution are obtained. , the four graphene-PMMA ribbons according to Figure 1B The form was transferred to a PET substrate, washed to remove PMMA.

[0069] 3. Coat the two ends of the long side of the graphene with conductive silver glue, lead out the wires, and dry and solidify.

[0070] 4. Seal the silver electrodes at both ends of the graphene with sealing silica gel.

[0071] Attaching the device to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com