Elastic cam adjusting device of coke oven tamping machine

A technology of elastic cam and adjusting device, which is applied in coking ovens, mechanical treatment of coal loaded into the furnace, petroleum industry, etc., can solve the problems of reducing the service life of gears, reduce maintenance costs, improve operation quality, and improve adjustment efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

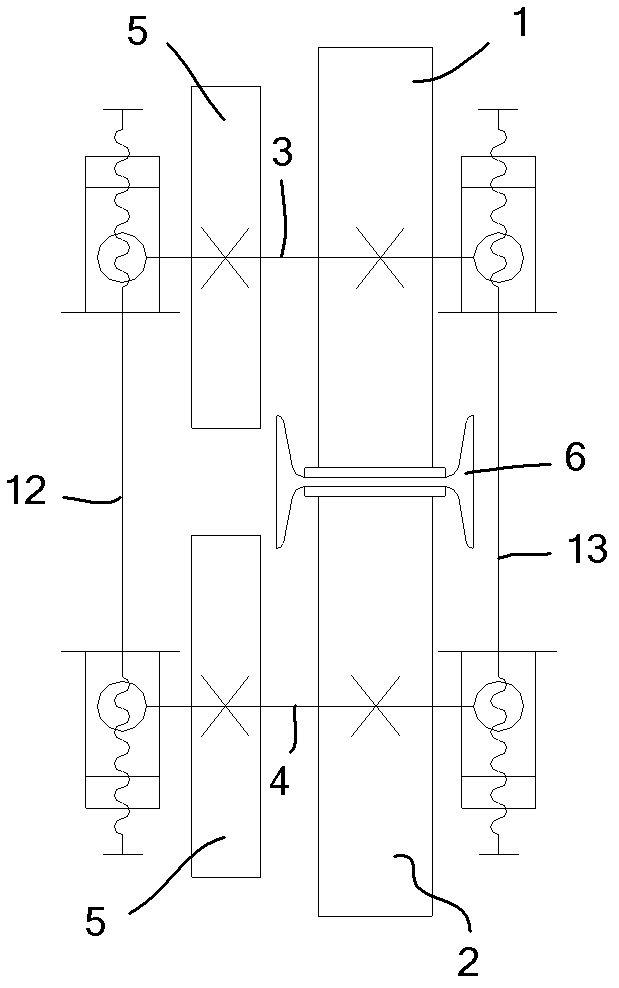

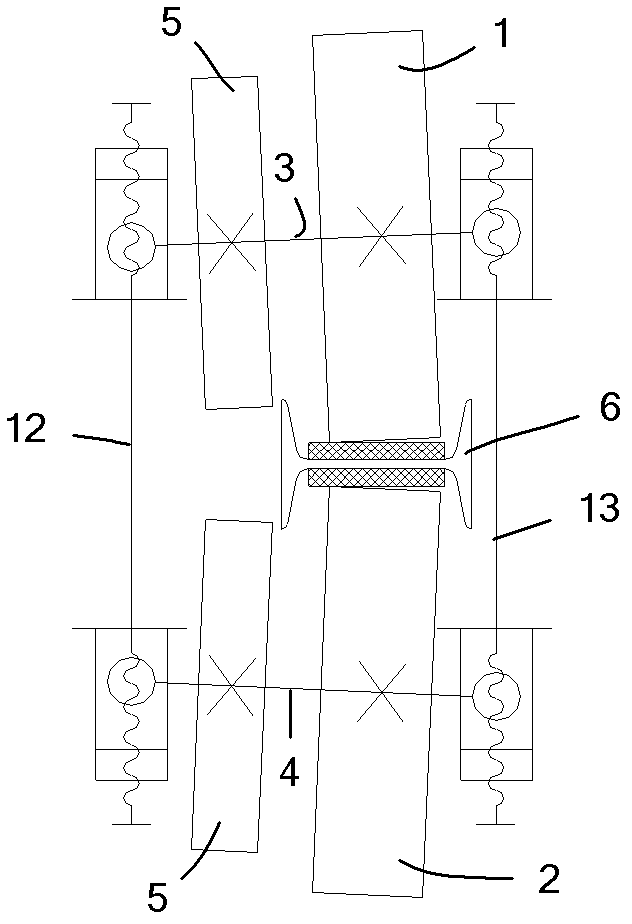

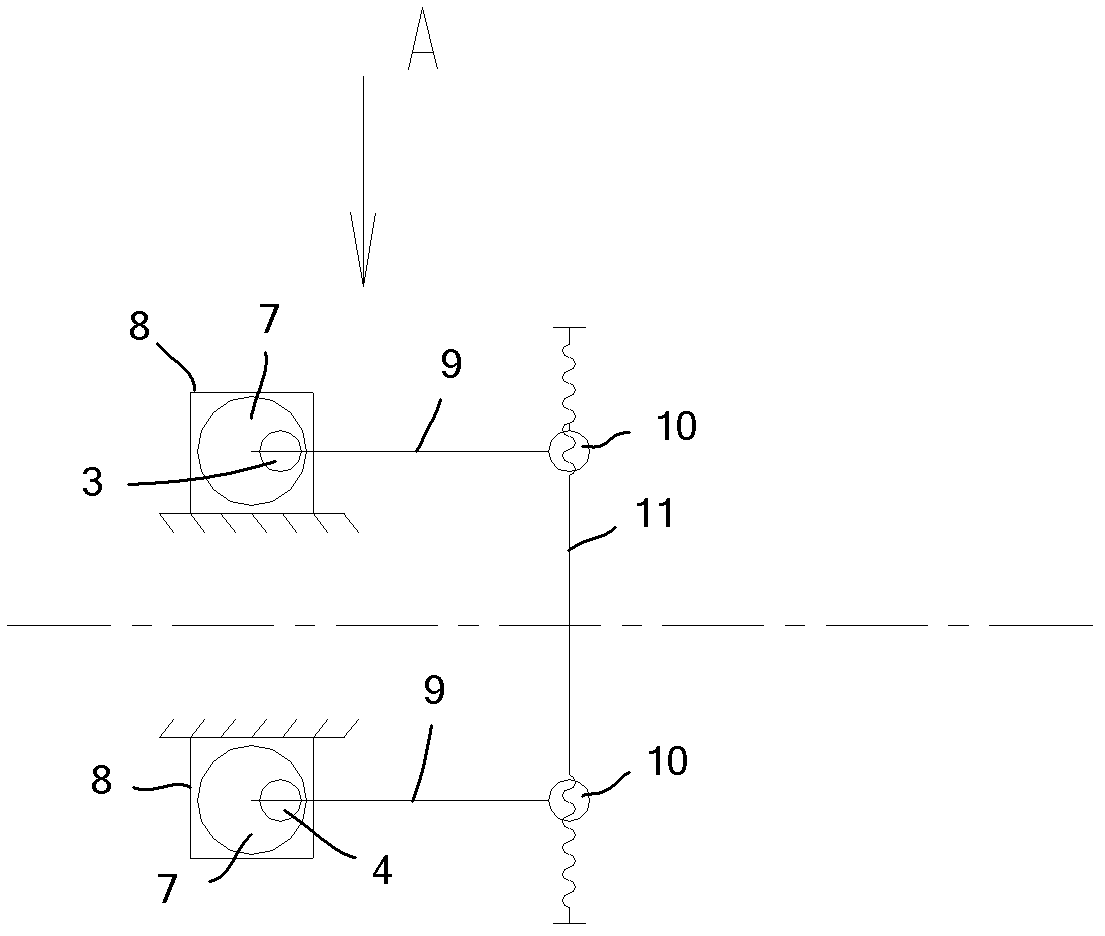

[0017] As in the background technology, such as figure 1 and figure 2 As shown, the present invention includes a first elastic cam 1 and a second elastic cam 2, the first elastic cam 1 is installed on the first camshaft 3, the second elastic cam 2 is installed on the second camshaft 4, and the first camshaft 3 and the second camshaft 4 are equipped with transmission gears 5 respectively. The first elastic cam 1 and the second elastic cam 2 frictionally hold the hammer rod 6 , and the transmission gear 5 meshes with other gears for transmission. The hammer ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com