Light-bead leakage-proof cement paste for well cementation and manufacturing technology

A technology of cement slurry and oil well cement, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor stability of cement slurry, formations prone to pressure leakage, and insignificant changes in volume pressure, etc., to achieve Increase the strength of the slurry structure, avoid formation leakage, and improve the effect of the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: This light bead anti-leakage cement slurry for well cementing is made by compounding G grade oil well cement and light bead according to the weight ratio, wherein:

[0047] 70 parts of G grade oil well cement;

[0048] 30 parts of light beads;

[0049] 80 parts of water;

[0050] Grade G oil well cement (this cement is available in cement manufacturers all over the country and is a general material), light beads were purchased from Gansu Qingyang Yuhui Building Materials Co., Ltd. Tel: 0934-6659691 Mobile: 15109342598.

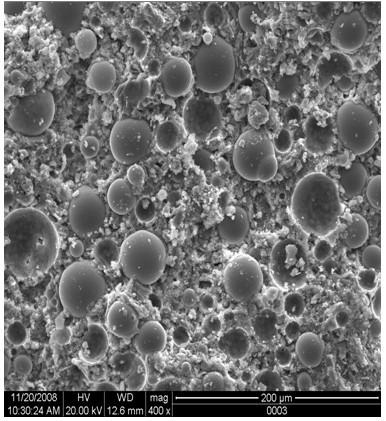

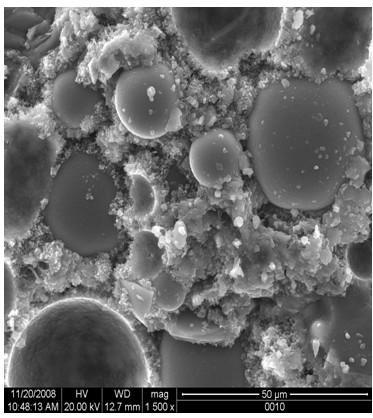

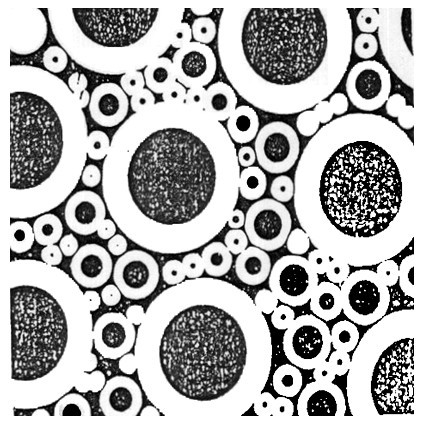

[0051] The light beads are light-weight materials compounded from silicon-aluminum ultra-light material components, with a particle size of 60 μm, a large specific surface area, and low water absorption. Therefore, the prepared cement paste has good fluidity and stability. At the same time, it can improve the high temperature resistance of cement stone, prevent the decline of cement stone strength under high temperature conditions, and impr...

Embodiment 2

[0078] Concrete preparation step is identical with embodiment 1 difference is that selection parameter is different:

[0079] 60 parts of G grade oil well cement;

[0080] 10 parts of light beads;

[0081] 65 parts of water.

[0082] The particle size of light beads is 30μm,

[0083] The density of the cement slurry system is 1.24g / cm 3 ;

[0084] The thickening time is 180min;

[0085] Described free water volume ratio is 1.6%;

[0086] The compressive strength is 24 hours compressive strength 4MPa;

[0087] The water-solid ratio is 0.65;

[0088] The addition of the light beads accounts for 10% of the total weight.

Embodiment 3

[0090] Concrete preparation step is identical with embodiment 1, and difference is that selection parameter is different:

[0091] G grade oil well cement 90 parts;

[0092] 40 parts of light beads;

[0093] 95 parts of water;

[0094] The particle size of light beads is 80μm,

[0095] The density of the cement slurry system is 1.60g / cm 3 ;

[0096] The thickening time is 300 min;

[0097] Described free water volume ratio is 4.1%;

[0098] The compressive strength is that the 24-hour compressive strength is greater than 7MPa;

[0099] The water-solid ratio is 0.95;

[0100] The added amount of the light beads accounts for 10%-40% of the total weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com