Method for preparing polyphenyl acetylene microballoon spheres

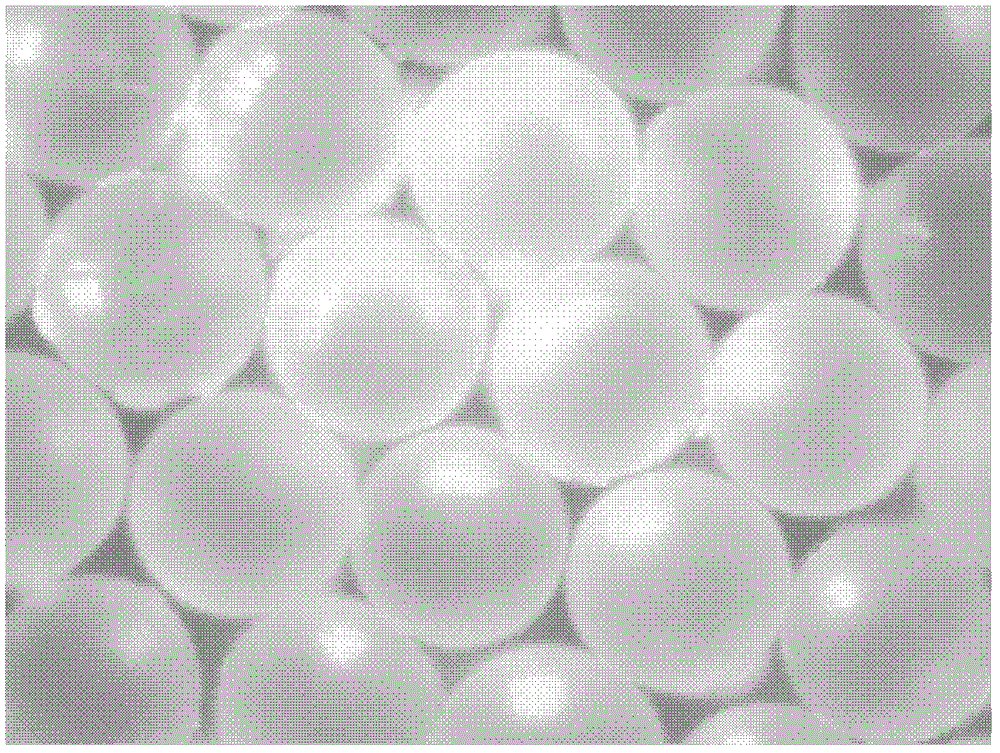

A technology for poly(p-phenylene vinylene) and microspheres is applied in the field of preparation of poly(p-phenylene vinylene) microspheres, which can solve the problems of lack of uniform size microspheres and the like, and achieve the effects of simple production, low energy consumption, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

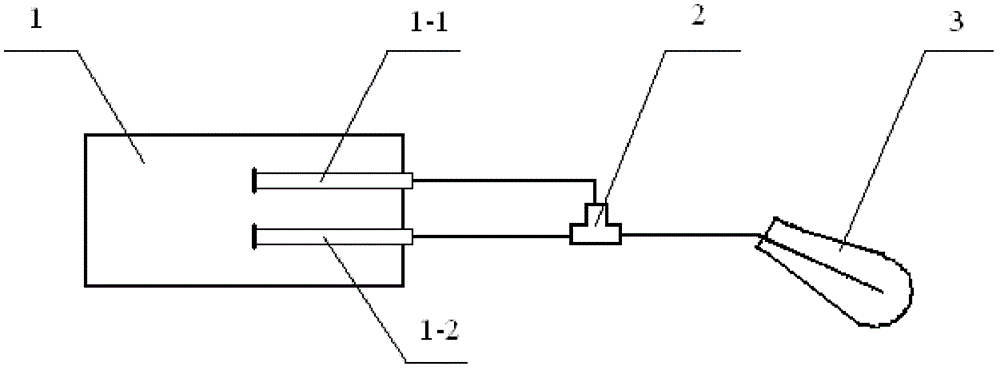

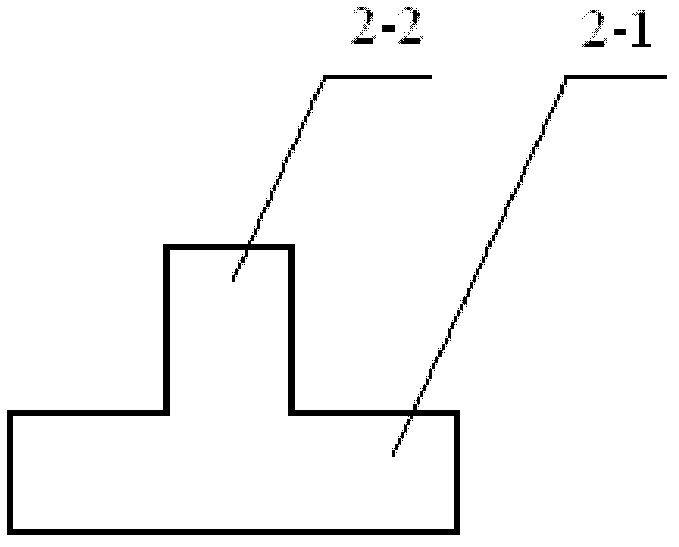

[0014] Specific embodiment one: present embodiment is the preparation method of poly(p-phenylene vinylene vinylene microsphere), and it is realized by following steps: 1, the preparation of disulfide salt: be 1g according to the mass volume ratio of dichloromethylbenzene and tetrahydrofuran: 1.3 ~ 1.6mL, the volume ratio of methanol and tetrahydrofuran is 10:1, weigh dichloromethylbenzene, methanol and tetrahydrofuran respectively, then mix dichloromethylbenzene, methanol and tetrahydrofuran to obtain a mixed solution, and then mix the The temperature of the solution is raised to 50-60°C, then kept at a constant temperature for 6-10 hours, then cooled to room temperature, and then distilled under reduced pressure until the volume is one-third of the original volume, and the concentrated solution is obtained after cooling to room temperature, and then the concentrated solution is used for The acetone at ℃ is reverse-precipitated to obtain a precipitate, and then the precipitate ...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the reduced-pressure distillation adopts a rotary evaporator and is carried out in a constant temperature water bath at 30° C. to 40° C. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0027] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 1, the specific operation steps of reprecipitating the concentrated solution with acetone at 0-5°C are as follows: take acetone at 0-5°C into the container, Then use a pipette to add the concentrated solution dropwise to the acetone at 0-5°C, stir, and filter to obtain a precipitate, wherein the volume ratio of the dropwise amount of the concentrated solution to the acetone at 0-5°C is 1: 10-15. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0028] In this embodiment, preferably, 10-15 mL of the concentrated solution is added dropwise to 150 mL of acetone at 0-5° C. for reverse precipitation. Only take 10-15mL of the concentrated solution each time until the concentrated solution is reverse-precipitated completely.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com