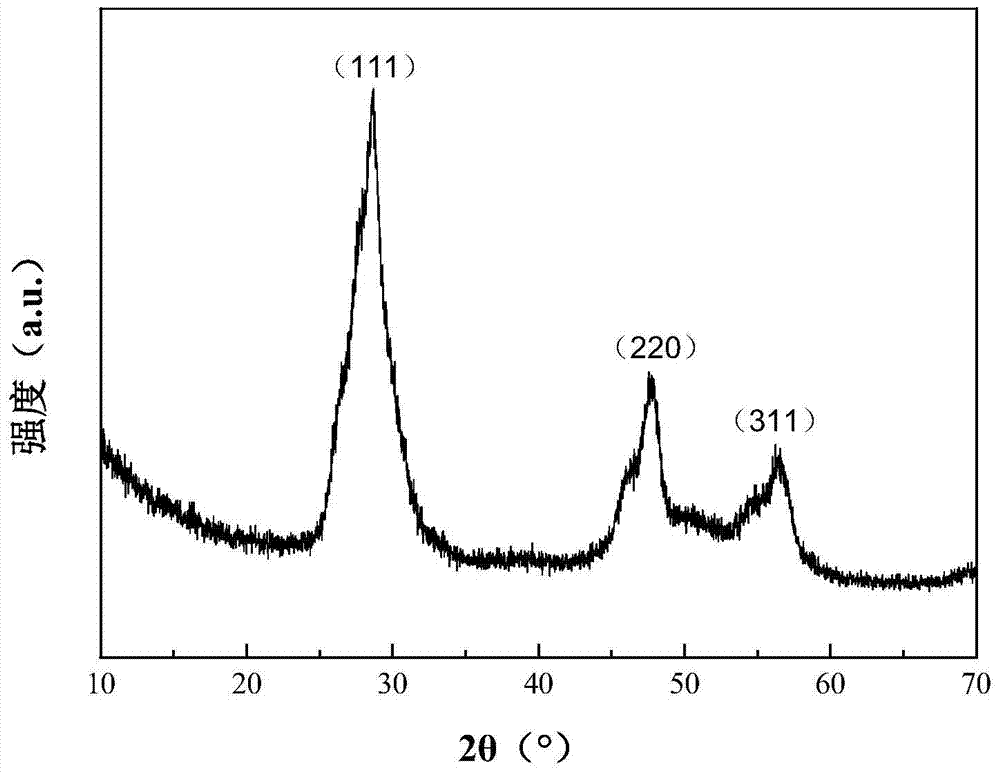

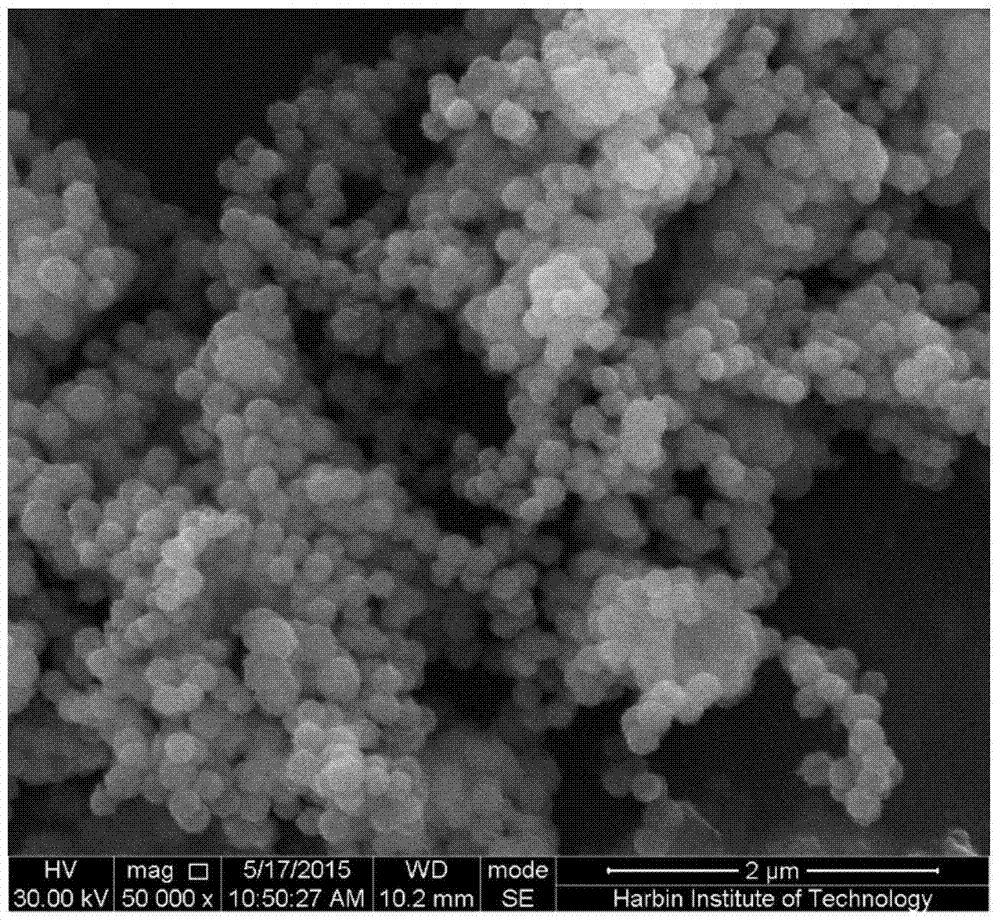

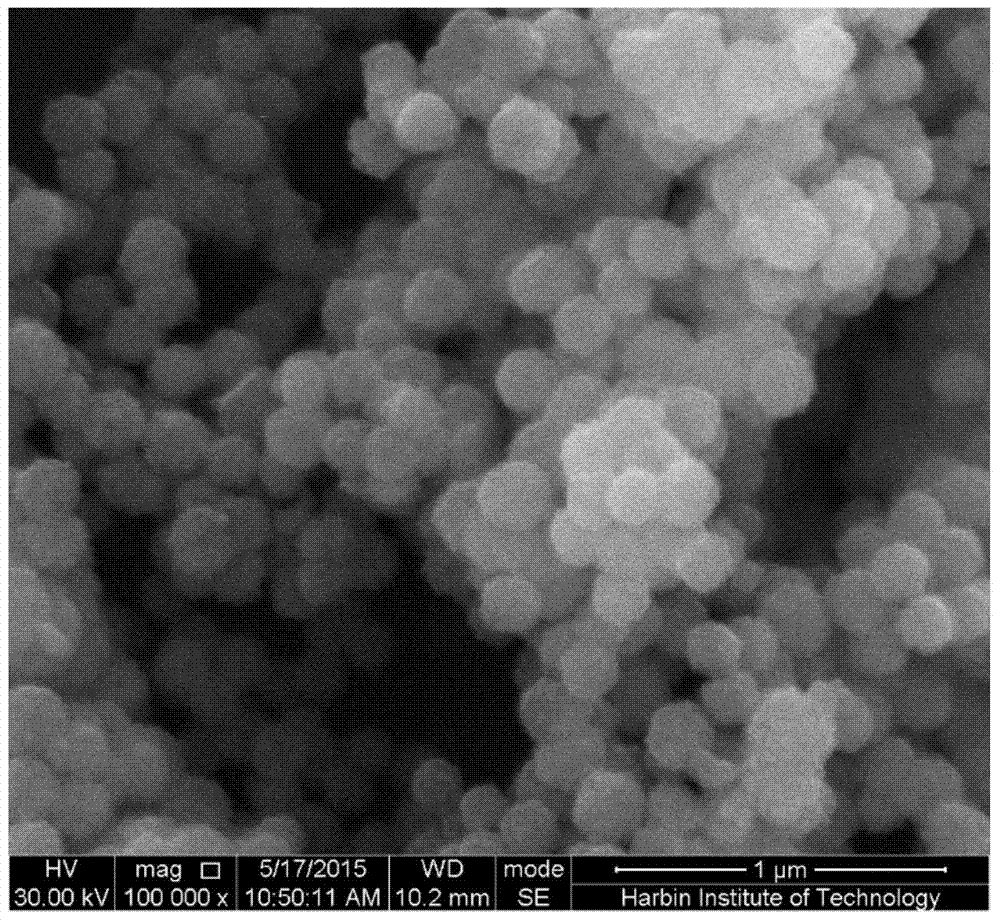

A visible-light-responsive cubic sphalerite-structured cd x zn 1‑x Preparation method of s solid solution photocatalyst

A cubic sphalerite and photocatalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and hydrogen production, can solve the problems of low hydrogen production rate and high cost, and achieve simple preparation process, low cost, The effect of high utilization rate of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0043] Specific implementation mode 1: This implementation mode is a Cd with cubic sphalerite structure responding to visible light x Zn 1-x The preparation method of S solid solution photocatalyst is finished according to the following steps:

[0044] One, the Zn (Ac) 2 2H 2 O and Cd(Ac) 2 2H 2 O was added to distilled water, and then stirred at a stirring speed of 1r / min to 5r / min for 20min to 90min to obtain a mixed solution of zinc acetate and cadmium acetate;

[0045] Zn(Ac) described in step one 2 2H 2 O and Cd(Ac) 2 2H 2 The substance ratio of O is (1.5~9):1;

[0046] Zn(Ac) described in step one 2 2H 2 O and Cd(Ac) 2 2H 2 The volume ratio of the total substance amount of O to distilled water is 6mmol:(20mL~30mL);

[0047] 2. Add thiourea to distilled water, and then stir at a stirring speed of 1r / min to 5r / min for 30min to 120min to obtain a thiourea solution;

[0048] The volume ratio of the amount of substance of thiourea described in step 2 to distill...

specific Embodiment approach 2

[0068] Specific embodiment two: the difference between this embodiment and specific embodiment one is: Zn(Ac) described in step one 2 2H 2 O and Cd(Ac) 2 2H 2 The substance molar ratio of O is (1.5-5):1. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0069] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: Zn(Ac) described in step one 2 2H 2 O and Cd(Ac) 2 2H 2 The volume ratio of the total substance amount of O to distilled water is 6mmol:(20mL~25mL). Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com