Preparation of isononyl isononanoate and application of isononyl isononanoate in cosmetic

A technology of isononyl isononanoate and isononanoic acid, which is applied in the preparation of carboxylic acid esters, cosmetics, cosmetics, etc., and can solve the problems that no one has reported the preparation of isononyl isononanoate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

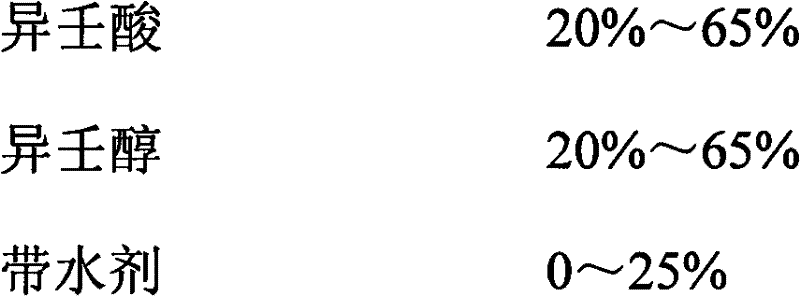

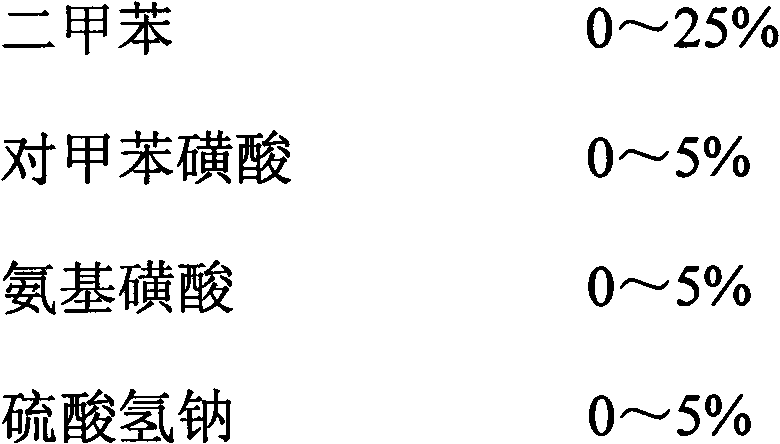

[0013] The preparation of embodiment 1 isononyl isononanoate (p-toluenesulfonic acid catalytic method)

[0014] Add isononanoic acid, isononanol, water-carrying agent (using cyclohexane or xylene as water-carrying agent), p-toluenesulfonic acid . Heat, stirring to dissolve the solids. After the solid dissolves, keep stirring at a constant speed. When the temperature reaches about 90°C, start to reflux and keep the reflux for 1 to 5 hours until no more water is generated and the reaction ends. Then cool to room temperature, add appropriate amount of NaHCO 3 Saturated solution (or sodium carbonate solution), standing to separate the organic layer, and then washing with water, the organic layer is distilled under reduced pressure, and the corresponding fractions are collected, which is the isononyl isononanoate compound of the present invention.

Embodiment 2

[0015] The preparation of embodiment 2 isononyl isononanoate (sulfamic acid catalytic method)

[0016] Add isononanoic acid, isononanol, water-carrying agent (cyclohexane or xylene is used as water-carrying agent) and sulfamic acid in the reactor equipped with stirrer, thermometer, reflux condenser and water separator. Heat, stirring to dissolve the solids. After the solid dissolves, keep stirring at a constant speed. When the temperature reaches about 90°C, start to reflux and keep the reflux for 1 to 5 hours until no more water is generated and the reaction ends. Then cool to room temperature, add appropriate amount of NaHCO 3 Saturated solution (or sodium carbonate solution), standing to separate the organic layer, and then washing with water, the organic layer is distilled under reduced pressure, and the corresponding fractions are collected, which is the isononyl isononanoate compound of the present invention.

Embodiment 3

[0017] The preparation of embodiment 3 isononyl isononanoate (sodium bisulfate catalyzed method)

[0018] Add isononanoic acid, isononanol, water-carrying agent (using cyclohexane or xylene as water-carrying agent) and sodium bisulfate into the reactor equipped with stirrer, thermometer, reflux condenser and water separator. Heat, stirring to dissolve the solids. After the solid dissolves, keep stirring at a constant speed. When the temperature reaches about 90°C, start to reflux and keep reflux for 1 to 5 hours until no more water is generated and the reaction ends. Then cool to room temperature, add appropriate amount of NaHCO 3 Saturated solution (or sodium carbonate solution), standing to separate the organic layer, and then washing with water, the organic layer is distilled under reduced pressure, and the corresponding fractions are collected, which is the isononyl isononanoate compound of the present invention.

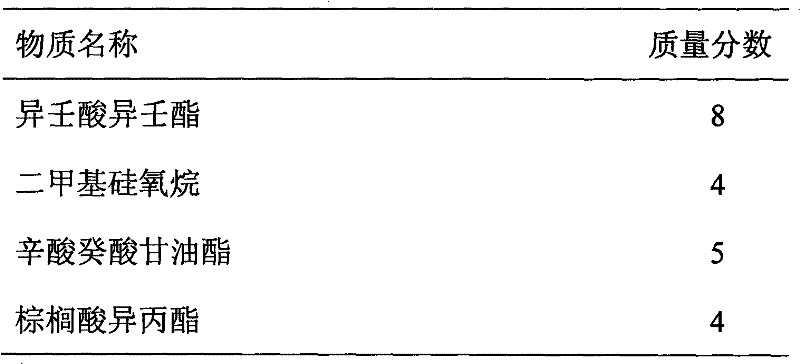

[0019] 2. Preparation of cosmetics containing isononyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com