Drilling fluid and preparation method thereof

A technology of drilling fluid and coating agent, applied in the field of oil and gas field drilling, can solve the problem that it is suitable for one kind of formation, such as sandstone formation, mud shale formation or salt gypsum formation, the drilling fluid performance is single, does not have broad-spectrum type, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

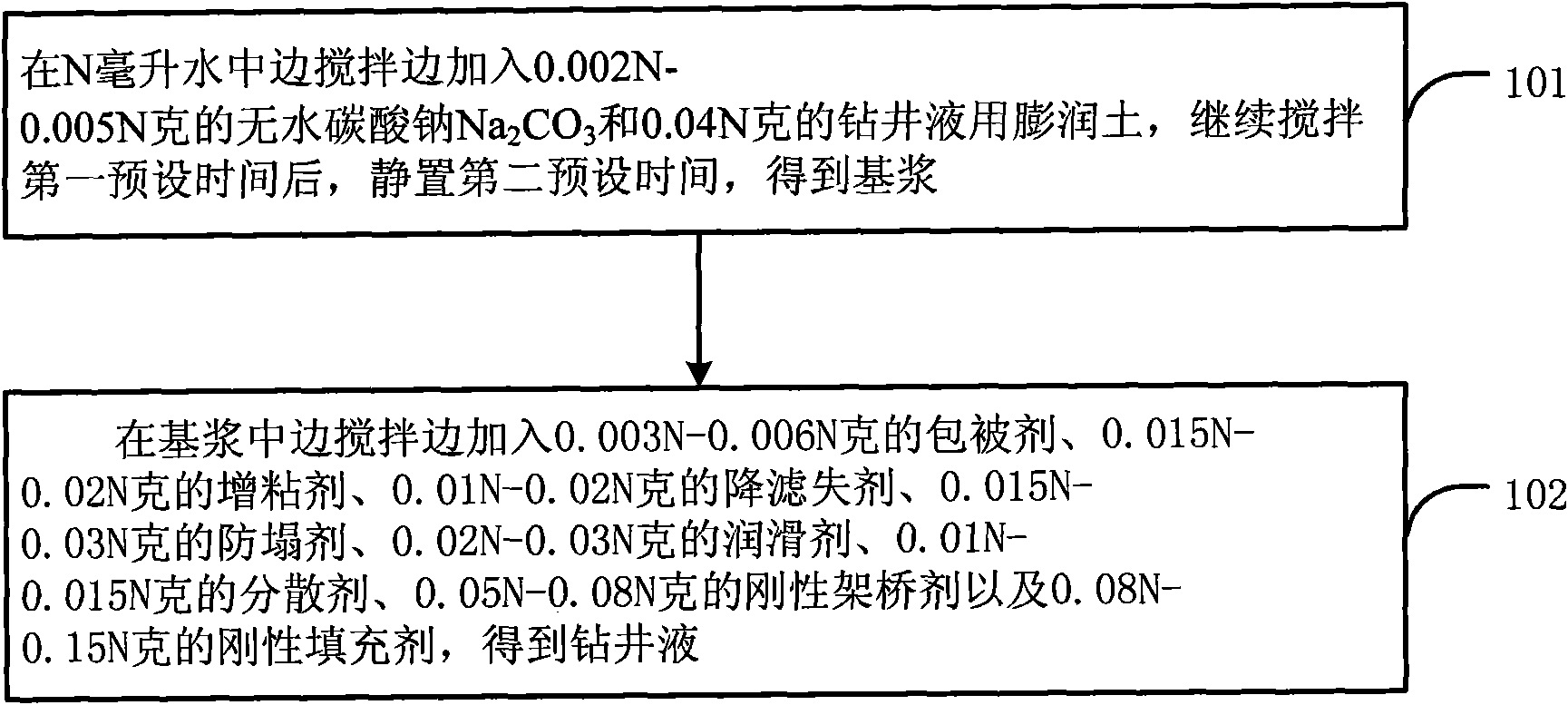

Method used

Image

Examples

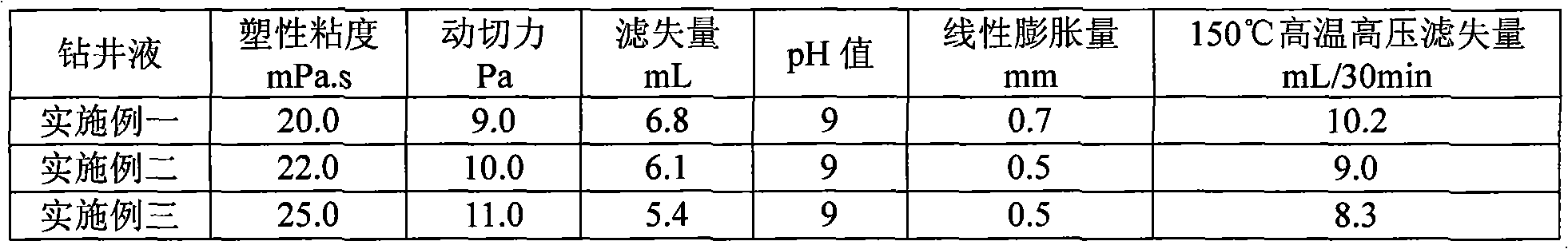

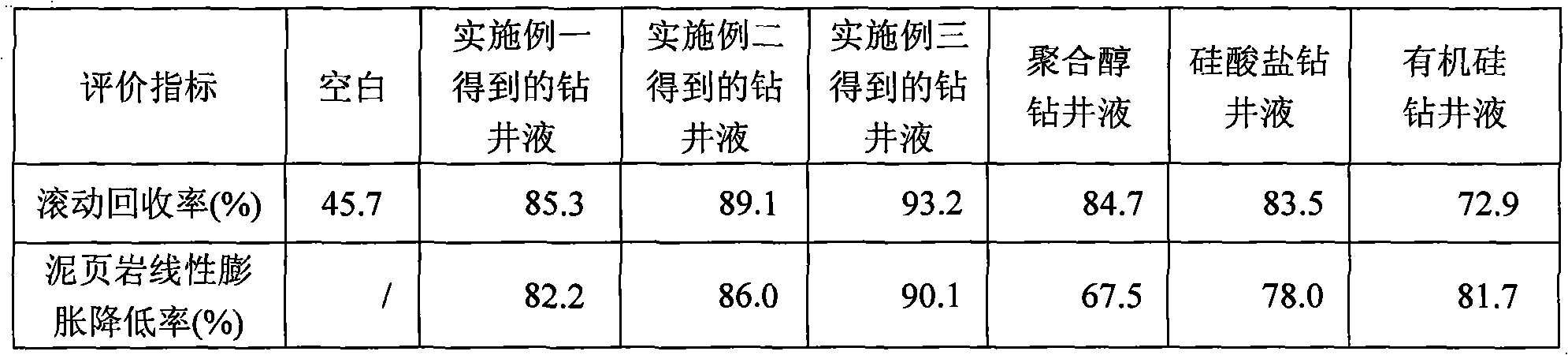

Embodiment 1

[0045] (1.1) Preparation of base slurry: In N milliliters of water, add 0.003 N grams of anhydrous sodium carbonate Na 2 CO 3 and 0.04N grams of bentonite for drilling fluid, continue to stir for more than 16 hours, and then let stand for 24 hours;

[0046] (1.2) In the base slurry, add various treatment agents in the following dosages while stirring:

[0047] Coating agent: 0.003N grams of natural polymer coating agent IND30;

[0048] Viscosifier: 0.015N grams of biopolymer graft modification GEL30;

[0049] Fluid loss additive: 0.01N grams of medium viscosity carboxymethylcellulose CMC-MV;

[0050] Anti-slump agent: 0.015N grams of polyalcohol PE-1:

[0051] Lubricant: 0.02N grams of non-toxic lubricant FXRH;

[0052] Dispersant: 0.01N grams of sodium dodecylbenzenesulfonate ABS:

[0053] The rigid bridging agent is 0.05N grams of rice bran:

[0054] The rigid filler is 0.08 N grams of oil soluble resin.

[0055]In the present embodiment one, if N gets 100, then spec...

Embodiment 2

[0057] (2.1) Preparation of base slurry: in N milliliters of water, add 0.003 N gram of anhydrous sodium carbonate Na CO 3 and 0.04 gram of bentonite for drilling fluid while stirring, continue stirring for more than 16 hours, and then let stand for 24 hours;

[0058] (2.2) In the base slurry, add various treatment agents in the following dosages while stirring:

[0059] Coating agent: 0.0045 N grams of high-viscosity polyanionic cellulose PAC-HV;

[0060] Viscosifier: 0.018N grams of high-viscosity carboxymethylcellulose CMC-HV:

[0061] Filtrate reducer: 0.015N grams of carboxymethyl starch CMS;

[0062] Anti-slump agent: 0.015N grams of polyalcohol JLX and 0.008N grams of cationic emulsified bitumen PC-1:

[0063] Lubricant: 0.025N grams of ink RH-3:

[0064] Dispersant: 0.013N grams of octylphenol polyoxyethylene ether OP-10;

[0065] Rigid bridging agent: 0.065 N grams of cottonseed hulls;

[0066] Rigid filler: 0.115 N grams of walnut shells.

[0067] In the presen...

Embodiment 3

[0069] (3.1) Preparation of base slurry: in N milliliters of water, add 0.002N-0.005N grams of anhydrous sodium carbonate Na2CO3 and 0.04 grams of bentonite for drilling fluid while stirring, continue stirring for more than 16 hours, and then let stand for 24 hours;

[0070] (3.2) In the base slurry, add various treatment agents in the following dosages while stirring:

[0071] Coating agent: 0.006N grams of acrylamide multi-polymer Coater-10;

[0072] Viscosifier: 0.02 N grams of high-viscosity carboxymethylcellulose CMC-HV;

[0073] Fluid loss control agent: 0.02 N grams of sulfomethyl phenolic resin SMP;

[0074] Anti-slump agent: 0.01N grams of sulfonated asphalt FT-1 and 0.02N grams of non-fluorescent white asphalt NFA-25;

[0075] Lubricant: 0.03N grams of vegetable oil modified lubricant CX-3;

[0076] Dispersant: 0.015N grams of sorbitan ester SP80;

[0077] Rigid bridging agent: 0.04N grams of sawdust and 0.04N grams of corn cob;

[0078] Rigid fillers: 0.1 N gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com