Biologic multi-element dual-organic compound fertilizer, production method and application thereof

A production method and multi-element technology, applied in the field of fertilizers, can solve problems such as waste and nutrient deficiency, and achieve the effects of convenient application, improved fertilizer utilization rate, and highly targeted fertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

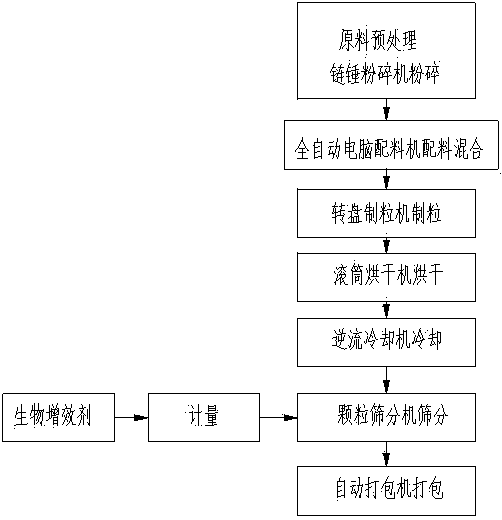

Image

Examples

Embodiment 1

[0101] Embodiment 1, the preparation of biological synergist

[0102] 1) Ingredients (1000kg): Choose fresh, dry, mildew-free coarse bran and wheat bran as raw materials. According to the amount of 800kg of coarse bran and 200kg of wheat bran needed to produce 1 ton of synergist, it is spread on the ground (or in a mixer), fully mixed and then flattened.

[0103] 2) Adjust humidity and PH: Weigh 3-4kg of alkali and dissolve it in 45kg of clear water to fully dissolve, stir evenly and spray it on the bran, mix well, without wet mass, use a wide range of PH1-14. In the demonstration paper test, the pH is 7.2 and the water content is about 40%. (Note: The dosage of alkali and water is an empirical figure, which should be determined according to the dry and wet and PH of the raw material).

[0104] 3) Packing: use cloth bags or woven bags to pack materials, each bag is about 10kg, it is not advisable to pack too much or too tight, so as not to affect the sterilization effect, an...

Embodiment 2

[0117] Embodiment 2, the production of biological multi-element dual-machine compound fertilizer (type I product):

[0118] The production of type I product biological multi-element dual-machine compound fertilizer is as follows:

[0119] Get calcium, magnesium, sulfur, silicon element 10kg, zinc, boron, manganese, copper, iron, molybdenum trace elements 5kg, oil dry (on dry basis) 100kg, silkworm sand (on dry basis) 60kg, pigeon manure ( On a dry basis) 50kg, stir, stir evenly (this material is referred to as the first mix A), and then pulverize it to less than 1 mm with a hammer mill. Take urea, potassium sulfate, and monoammonium phosphate and pulverize them to less than 1 mm with a chain pulverizer.

[0120] Set the batching amount of each raw material on the automatic computer batching machine (first mix A 225kg, urea 435kg, potassium sulfate 180kg, monoammonium phosphate 150kg), and transfer the crushed raw materials to the mixer according to the set batching amount. F...

Embodiment 3

[0135] Embodiment 3, the production of biological multi-element dual-machine compound fertilizer (II type product):

[0136] The production of type II product biological multi-element dual-machine compound fertilizer is as follows:

[0137] Take 145kg of oil (on a dry basis), 5kg of calcium, magnesium, sulfur, and silicon elements, and 4kg of zinc, boron, manganese, copper, iron, and molybdenum trace elements, and stir, and stir evenly (this material is referred to as the first mixed B ) and then pulverized with a hammer mill to less than 1 mm. Take ammoniated calcium superphosphate and potassium chloride and pulverize them to less than 1 mm with a chain pulverizer respectively. Take ammonium chloride and pulverize it with a hammer mill to less than 1 mm.

[0138] Set the batching amount of each raw material on the automatic computer batching machine (first mixing B 154kg, ammonium chloride 400kg, ammoniated calcium superphosphate 150kg, potassium chloride 290kg), and crush ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com