Building hollow brick using industrial tailings and preparation method thereof

A technology for industrial tailings and hollow bricks is applied in the field of building hollow bricks to achieve good compressive strength, realize resource utilization and protect the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

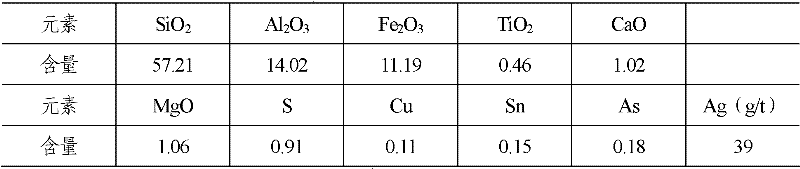

Method used

Image

Examples

Embodiment 1

[0035] The present embodiment utilizes the building hollow brick of industrial tailings, and by weight percentage, its raw material composition comprises: iron tailings (grain size greater than 180 mesh particle weight accounts for 20% of total weight) 40%, fly ash 10%, ceramsite 30% %, water glass 13% (water glass modulus 2.8), polyaluminum phosphate accounts for 3% of water glass weight, sodium sulfate accounts for 1% of water glass weight, commonly used polycarboxylate water reducer (solid content is 40wt%) 0.5%, the balance in water.

[0036] The method for preparing building hollow bricks by using industrial tailings, the process steps of the method are: raw material metering and mixing-vibration (or pressure) molding-curing-demolding-curing-finished product; after the above-mentioned raw materials are fully mixed, the mixture Put it into a hollow brick mould, vibrate and compact it, and cure it at 20°C for 24 hours, demould after curing, and continue curing at room tempe...

Embodiment 2

[0038]The present embodiment utilizes the building hollow brick of industrial tailings, and by weight percentage, its raw material composition comprises: Copper tailings (grain size is greater than 180 order particle weight accounts for 25% of total weight) 40%, fly ash 15%, coarse sand 25% %, water glass 9% (water glass modulus 2.6), sodium sulfate accounts for 2% of the weight of water glass, commonly used lignin water reducer 0.5%, water balance.

[0039] The method for preparing building hollow bricks by using industrial tailings, the process steps of the method are: raw material metering and mixing-vibration (or pressure) molding-curing-demolding-curing-finished product; after the above-mentioned raw materials are fully mixed, the mixture Put it into a hollow brick mould, vibrate it compactly, cure it at 20°C for 2 days, demould after curing, and continue curing it at room temperature for 28 days to obtain a finished product with a porosity of 45% and a compressive strengt...

Embodiment 3

[0041] The present embodiment utilizes the construction hollow brick of industrial tailings, by weight percentage, and its raw material composition comprises: iron tailings (particle size greater than 180 mesh weight accounts for 30% of total weight) 45%, slag 18%, pebble 20%, boric acid Sodium 5%, commonly used naphthalene-based water reducer 0.3%, aluminum sulfate 1%, water balance.

[0042] The method for preparing building hollow bricks by using industrial tailings, the process steps of the method are: raw material metering and mixing-vibration (or pressure) molding-curing-demolding-curing-finished product; after the above-mentioned raw materials are fully mixed, the mixture Put it into a hollow brick mould, vibrate and compact it, and cure it at 50°C for 10 hours, demould after curing, and continue to cure it at room temperature for 28 days to obtain a finished product with a porosity of 50% and a compressive strength of 11.5 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com