Novel liquid cement grinding aid and preparation method thereof

A cement grinding aid and liquid technology, which is applied in the field of new liquid cement grinding aid and its preparation, can solve the problems of urgent triethanolamine substitutes and high price of triethanolamine, so as to improve powder efficiency, save power consumption and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

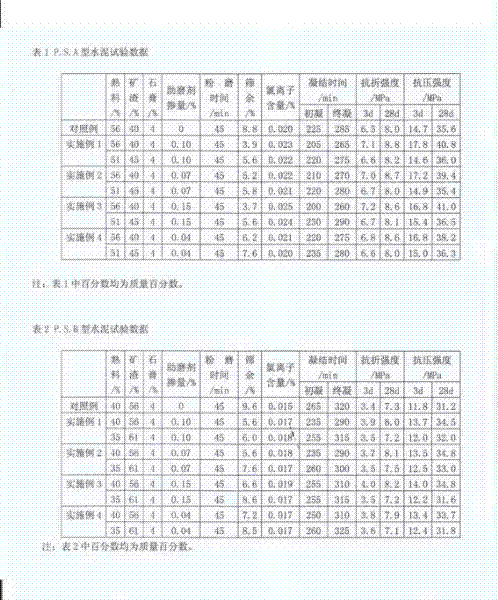

Image

Examples

Embodiment 1

[0016] First, add 15 kg of molasses to 38 kg of water, heat and stir slightly at a temperature of 30°C, and after it is completely dissolved, successively add 20 kg of triisopropanolamine, 15 kg of glycerin, 4 kg of diethylene glycol, and 5 kg of diethylene glycol. Propylene glycol and 5 kg of ethylene glycol are added therein and stirred evenly, after cooling and filtering.

Embodiment 2

[0018] First, add 10 kg of molasses to 45 kg of water, heat and stir slightly at a temperature of 30°C. After it is completely dissolved, successively add 25 kg of triisopropanolamine, 10 kg of glycerin, 2 kg of diethylene glycol, and 8 kg of diethylene glycol. Propylene glycol and 10 kg of ethylene glycol are added therein and stirred evenly, after cooling and filtering.

Embodiment 3

[0020] First, add 20 kg of molasses to 30 kg of water, heat and stir slightly at a temperature of 30°C. After it is completely dissolved, successively add 10 kg of triisopropanolamine, 20 kg of glycerin, 6 kg of diethylene glycol, and 2 kg of diethylene glycol. Propylene glycol and 3 kg of ethylene glycol are added therein and stirred evenly, after cooling and filtering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com