Method for manufacturing microcrystalline glass utilizing smelting waste slag and CRT (Cathode Ray Tube) waste glass

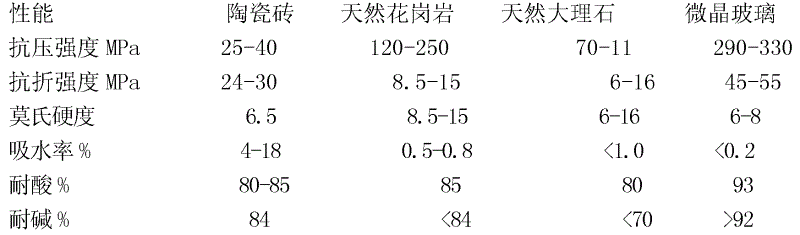

A technology of waste glass and glass-ceramics, which is applied in the field of building materials, can solve problems such as waste of state-owned resources, excessive consumption, and land occupation, and achieve the goal of avoiding environmental damage, excellent performance, high wear resistance and chemical corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

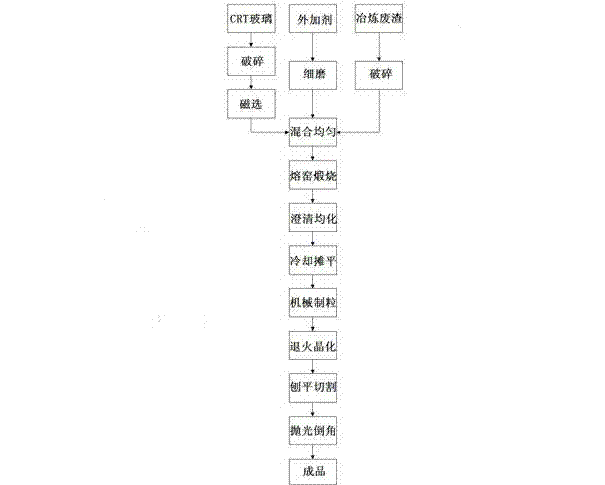

[0028] Raw materials are used according to weight ratio: smelting waste slag: 45% of waste slag from oxygen-enriched side-blown smelting low-nickel matte, 45% of CRT waste glass, 4% of calcite, 1% of cobalt oxide admixture, 5% of quartz sand, according to the following process Process manufacturing:

[0029] 1) CRT waste glass is crushed by a vertical crusher first, and after magnetic separation and iron removal, it is mixed evenly and the particle size is controlled at 2-3mm;

[0030] 2) Smelting waste slag is crushed into granules by ball mill, and its fineness is controlled at 2-3mm;

[0031] 3) Calcite, quartz sand and admixture are preprocessed into powder or pellets with a ball mill, with a fineness of 0.2-0.3mm;

[0032] 4) After mixing the above three materials 1), 2) and 3 evenly, they enter the industrial kiln through the conveyor belt;

[0033] 5) A special industrial kiln made of refractory materials such as high-alumina bricks or zirconia fused products. The abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com